LED Light Fittings | Hazardous Area Lighting Zone 2 22 | ATX MLEDNA70P5BU

hazardous area LED light fitting

Mercmaster

Appleton ATX MLEDNA70P5BU

Zone 2 (Gas) | Zone 22 (Dust) Hazardous Areas

Mercmaster LED light fittings, manufactured by Appleton ATX, deliver exceptional performance, efficiency and advanced engineering in hazardous area lighting. Designed to light hazardous areas such as parking garages, storage areas, oil refineries, chemical plants, water and sewage treatment and paper mills, using as little as 32 Watts of power.

The ATX Mercmaster LED light fitting can lower energy consumption while providing 60,000+ hours of running lamp life. The MLEDNA Mercmaster light fitting is suitable for use in wet and marine locations, making it an ideal choice for coastal locations.

In areas requiring better visibility and instant-on illumination, the range of Mercmaster LED light fittings provide a low maintenance, energy efficient solution.

Mercmaster is certified as NEC/CEC Class I, Division 2 and ATEX/IECEx Zone 2 and Zone 22 locations to provide safe and reliable lighting for hazardous area zones and explosive atmospheres.

- Category: Hazardous Area Lighting

- Product: LED Light Fitting

- Light Fitting Type: LED

- Manufacturer: Appleton ATX

- Range: Mercmaster – MLEDNA

- Technology: LED Lighting

- Lumen Output: 2300 lumens

- Voltage Range: 120-277Vac, 50/60Hz

- Input Power: 35/33 Watts

- Ambient Temperature: -40°C up to +65°C (-40°F up to +149°F)

- LED Light Fitting Weight: 8.8 kg (19.4 lbs)

- Colour Temperature CCT: 5650

- Colour Rendering Index CRI: 70

- LED Light Fitting Lamp Life: 60,000+ Hours

- NEMA Type: V

- Cable Entry: M20

- ATX MLEDNA70P5BU is ideal for use in Zone 2 Zone 22 hazardous area locations

- Hazardous Area Certified: ATEX & IECEx

- Floodlights ATEX Zone 1 | Floodlights ATEX Zone 2

- Light Fittings ATEX Zone 1 | Light Fittings ATEX Zone 2

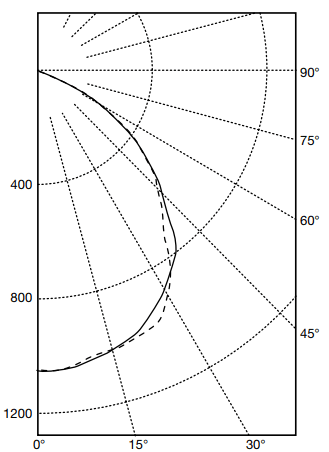

Photometric Data

LED Light Fittings: Lamps: ATX Mercmaster LED, Class I, Division 2, Polycarbonate Optic

Candela Distribution

| 0.0 | 22.5 | 45.0 | 67.5 | 90.0 | Flux | |

| 0 | 1054 | 1054 | 1054 | 1054 | 1054 | – |

| 5 | 1048 | 1047 | 1051 | 1047 | 1048 | 100 |

| 15 | 1016 | 1014 | 1016 | 1014 | 1016 | 287 |

| 25 | 977 | 961 | 941 | 961 | 977 | 442 |

| 35 | 805 | 779 | 824 | 779 | 805 | 497 |

| 45 | 583 | 607 | 603 | 607 | 583 | 465 |

| 55 | 408 | 425 | 411 | 425 | 408 | 358 |

| 65 | 185 | 146 | 139 | 146 | 185 | 133 |

| 75 | 5 | 5 | 4 | 5 | 5 | 9 |

| 85 | 1 | 0 | 0 | 0 | 1 | 1 |

| 90 | 0 | 0 | 0 | 0 | 0 | – |

Zonal Lumen Summary

| Zone | Lumens | % Fixture |

| 0-30 | 829 | 36.1 |

| 0-40 | 1326 | 57.7 |

| 0-60 | 2149 | 93.5 |

| 0-90 | 2292 | 99.7 |

CIE Type – Direct

| Plane | Spacing Criteria |

| 0-Deg | 90-Deg |

| 1.2 | 1.2 |

Flameproof & Explosion Proof – What Is the Difference?

The terms flameproof and explosion proof have the terminological meaning in that the electrical equipment intended for installation into a hazardous area zone is constructed using a such a design that an internal ignition (sparking) of a flammable atmosphere (gas, vapour or dust) will not be transmitted outside of the equipment and thereby preventing the ignition of surrounding flammables in potentially explosive atmospheres.

➡ More Hazardous Area Lighting: LED Light Fittings | Increased Safety Floodlights | Zone 1 Zone 2 Fluorescent Light Fittings | Explosion Proof Lighting Fittings | Flameproof Lighting Exd

Thorne & Derrick | Hazardous Area Lighting Specialists | Explosive Atmosphere Experts