Flanged Immersion Heater For Mildly Corrosive Solutions – Chromalox TMS

Chromalox TMS Flanged Immersion Heater

flanged immersion heaters

chromalox tms

Chromalox TMS flanged immersion heaters are suitable for heating gases and liquids such as water, oil, heat transfer fluid and corrosive solutions.

They are designed for use in tanks and pressurised vessels, they are easy to install as well as to maintain and provide heat for many processes. The direct immersion method is easily monitored and controlled and also energy efficient.

The Chromalox TMS immersion heater comes with a general purpose, moisture resistant or moisture resistant/explosion resistant terminal enclosure, stainless steel Thermowell and sheath elements.

The TMS immersion heater provides a power outputs up to 23W/In², 3-50 kW for use with 240V and 480V 1 & 3 phase supplies and has the following certifications for use in hazardous areas: UL Listed, CSA, cCSAus.

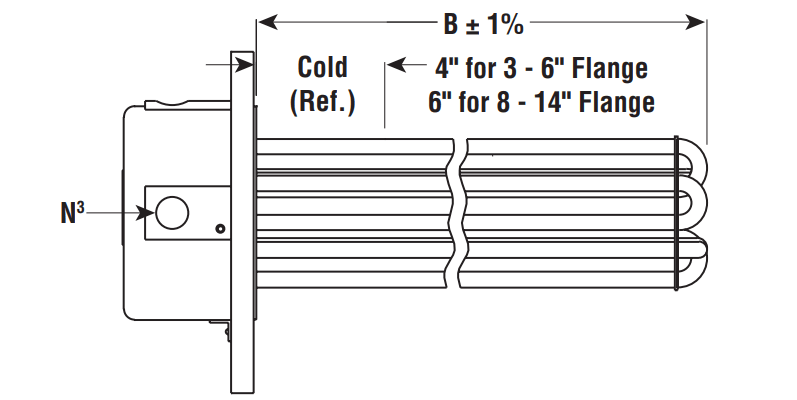

Chromalox TMS Dimensions

Chromalox TMS flanged Immersion Heater

Technical Information

| kW | Volts | CKT & Phase | DIM B (In) | DIM N (In) E1 : E2 : E4 |

Wt (lbs) |

| 3 Inch – 150 lb Steel Flange – 3 Stainless Steel Sheath Elements – 23 W/In² | |||||

| 3 | 240 | 1-1 | 18-1/16 | 1 : 3/4 : N/A | 16 |

| 3 | 240 | 1-3 | 18-1/16 | 1 : 3/4 : N/A | 16 |

| 3 | 480 | 1-1 | 18-1/16 | 1 : 3/4 : N/A | 16 |

| 3 | 480 | 1-3 | 18-1/16 | 1 : 3/4 : N/A | 16 |

| 4.5 | 240 | 1-1 | 25-3/16 | 1 : 3/4 : N/A | 17 |

| 4.5 | 240 | 1-3 | 25-3/16 | 1 : 3/4 : N/A | 17 |

| 4.5 | 480 | 1-1 | 25-3/16 | 1 : 3/4 : N/A | 17 |

| 4.5 | 480 | 1-3 | 25-3/16 | 1 : 3/4 : N/A | 17 |

| 6 | 240 | 1-1 | 33-1/16 | 1 : 3/4 : N/A | 18 |

| 6 | 240 | 1-3 | 33-1/16 | 1 : 3/4 : N/A | 18 |

| 6 | 480 | 1-1 | 33-1/16 | 1 : 3/4 : N/A | 18 |

| 6 | 480 | 1-3 | 33-1/16 | 1 : 3/4 : N/A | 18 |

| 7.5 | 240 | 1-3 | 40-9/16 | 1 : 3/4 : N/A | 19 |

| 7.5 | 480 | 1-3 | 40-9/16 | 1 : 3/4 : N/A | 19 |

| 9 | 480 | 1-1 | 48-1/16 | 1 : 3/4 : N/A | 21 |

| 9 | 480 | 1-3 | 48-1/16 | 1 : 3/4 : N/A | 21 |

| 9 | 240 | 1-3 | 48-1/16 | 1 : 3/4 : N/A | 21 |

| 5 Inch – 150 lb Steel Flange – 6 Stainless Steel Sheath Elements – 23W/In² | |||||

| 9 | 240 | 1-3 | 25-3/16 | 1 : 1 1/2 : 1 | 32 |

| 9 | 480 | 1-3 | 25-3/16 | 1 : 1 1/2 : 1 | 32 |

| 12 | 240 | 1-3 | 33-1/16 | 1 : 1 1/2 : 1 | 33 |

| 12 | 480 | 1-3 | 33-1/16 | 1 : 1 1/2 : 1 | 33 |

| 15 | 240 | 1-3 | 40-9/16 | 1 : 1 1/2 : 1 | 35 |

| 15 | 480 | 1-3 | 40-9/16 | 1 : 1 1/2 : 1 | 35 |

| 20 | 240 | 1-3 | 52-1/16 | 1 : 1 1/2 : 1 | 38 |

| 20 | 480 | 1-3 | 52-1/16 | 1 : 1 1/2 : 1 | 38 |

| 25 | 240 | 2-3 | 65-1/16 | 1 : 1 1/2 : 1 | 42 |

| 25 | 480 | 1-3 | 65-1/16 | 1 : 1 1/2 : 1 | 42 |

| 30 | 240 | 2-3 | 78-1/16 | 1 : 1 1/2 : 1 | 46 |

| 30 | 480 | 1-3 | 78-1/16 | 1 : 1 1/2 : 1 | 46 |

| 6 Inch – 150lb Steel Flange – 12 Stainless Steel Sheath Elements – 23W/In² | |||||

| 18 | 240 | 1-3 | 25-1/8 | 1 : 1 1/2 : 1 1/2 | 67 |

| 18 | 480 | 1-3 | 25-1/8 | 1 : 1 1/2 : 1 1/2 | 67 |

| 24 | 240 | 2-3 | 33 | 1 : 1 1/2 : 1 1/2 | 76 |

| 24 | 480 | 1-3 | 33 | 1 : 1 1/2 : 1 1/2 | 76 |

| 30 | 240 | 2-3 | 40-1/2 | 1 : 1 1/2 : 1 1/2 | 84 |

| 30 | 480 | 1-3 | 40-1/2 | 1 : 1 1/2 : 1 1/2 | 84 |

| 36 | 240 | 2-3 | 48 | 1 : 1 1/2 : 1 1/2 | 111 |

| 36 | 480 | 1-3 | 48 | 1 : 1 1/2 : 1 1/2 | 111 |

| 8 Inch – 150 lb Steel Flange – 18 Stainless Steel Sheath Elements – 23W/In² | |||||

| 30 | 240 | 3-3 | 32-7/8 | 1 : 3/4 : 1 1/2 | 112 |

| 30 | 480 | 3-3 | 32-7/8 | 1 : 3/4 : 1 1/2 | 112 |

| 40 | 240 | 3-3 | 43-11/16 | 1 : 3/4 : 1 1/2 | 125 |

| 40 | 480 | 3-3 | 43-11/16 | 1 : 3/4 : 1 1/2 | 125 |

| 50 | 240 | 3-3 | 51-7/8 | 1 : 3/4 : 1 1/2 | 130 |

| 50 | 480 | 3-3 | 51-7/8 | 1 : 3/4 : 1 1/2 | 130 |

| E1 – General Purpose Terminal Enclosure E2 – Moisture Resistant/Explosion Resistant E4 – Moisture Resistant for weights: A. For Wt. of 3″ flange with E2 enclosure add 3 lbs. to Wt. of E1 enclosure heater. B. For Wt. of 5 and 6″ flange with E4 enclosure add 7 lbs. to Wt. of E1 enclosure heater. C. For Wt. of 8″ flange with E4 enclosure add 10 lbs. to Wt. of E1 enclosure heater. |

|||||

Contact Thorne & Derrick for excellent customer service, competitive quotations and delivery from stock for Chromalox heaters

Explosion Proof Exd Flameproof Heaters | Exd Radiators | Exe Increased Safety Heaters | Explosion Proof Convection Heaters | Exd Flameproof Heaters | Distributed by Thorne & Derrick | Experts in Equipment for Explosive Atmospheres

Experts in Equipment for Explosive Atmospheres

Learn more about our ATEX & IECEx Product Innovations and how we deliver significant improvements to clients plant, people and operational safety in the explosive atmosphere industries – we service UK and international projects with a comprehensive range of certified Electrical, HVAC and Process Instrumentation equipment for the hazardous area industries.

Hazardous Area ELECTRICAL, MECHANICAL & PROCESS INSTRUMENTATION Specialists

Thorne & Derrick International distribute Electrical, Mechanical, Process & Instrumentation Equipment to the global hazardous area industries and are approved vendors to most leading oil, gas and petrochemical companies and their EPC’s.

T&D supply ATEX & IECEx Certified equipment for the detection, metering, flow measurement and heat tracing of potentially explosive gases in hazardous areas Zone 1 and Zone 2 (Explosive Gas) and Zone 21 and Zone 22 (Explosive Dust).

Hazardous Area Equipment | Gas Detection | Metering | Lighting | Process Instrumentation | Plugs & Connectors | Trace Heating

Chromalox Product Range | Hazardous Area Heating | Immersion Heaters | Trace Heating Cables