Detecting Gas | Duct Mounted SafEye Flammable Gas Detectors

Crowcon Duct Mounted SafEye Fixed Gas Detector

SafEye Duct Mounted Flammable gas Detectors

Detecting Gas

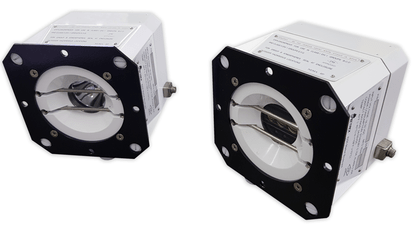

The Duct SafEye Open Path gas detector, from Crowcon, was specially designed and is widely used to monitor and alarm against ingress of hazardous gas concentrations into air intakes of turbine engines and HVAC air ducts. The formation and migration of gases and their possible penetration into safe places, control rooms, turbine engines, etc. is a substantial risk that must to be addressed.

Safety and operational engineers are required to provide adequate detection of these gas clouds in order to protect from these hazards.

For duct applications, over a small path across an air inlet, the SafEye system is designed to respond with a very high sensitivity. Full scale of 1 LEL.m for 2-6.6 ft. (0.6-2 m) wide inlet and full scale of 2.5 LEL.m for 6.6-23 ft. (2-7 m) wide inlet.

Due to the special design of the optics, the Duct SafEye range provides for a misalignment tolerance of 2° in all directions and is protected against false gas reading and alarms which are caused by partial obscuration and blocking, vibration, flexing or tilts.

The Duct Safeye system can be factory calibrated to detect specific gas mixtures that are associated with offshore production and processing and onshore installations.

Crowcon Duct Mounted SafEye Gas Detectors

Features

High Sensitivity

– Alarm up to 0.5 LEL.m

– 5 times more sensitive than the normal Open Path equipment

Fast Response

– Fast response time of 2 seconds (300 series) and ultra fast response of 1 second (200 series).

– 5 to 10 times faster than the commonly used Open Path detector and 20-50 times faster than the Point Detector.

Proven Technology Used in air ducts on FPSO’s and offshore rigs for British Petroleum (BP), Shell and ABB Lummus for turbines, air intakes, etc.

Low Maintenance High reliability, simple installation, alignment and maintenance, equipment not subject to poisoning.

Harsh Environment Specially designed to perform under extreme conditions such as high-speed airflows, high temperatures (up to 158˚F (70˚C)), humidity and corrosive gases, where point detectors may not be effective.

Standard Interface Options Standard 4-20 mA outputs or RS-485 output to allow networking (up to 64 detectors) to a central monitoring/PC system. This feature also enables easy maintenance, local and remote diagnostic tools.

Duct Mounted SafEye Gas Detectors

Specification

Electrical Specifications

- Power Supply: 24VDC nominal (18-32 VDC)

- Power Consumption: Detector: 150mA @ 24 VDC (200 mA Peak) | Source: 100mA @ 24 VDC (220 mA Peak)

- Electrical Connection: 2 x 3/4″ – 14NPT conduits or 2 x M25 x 1.5mm ISO

- Electrical Input Protection: Complete electrical interface protection against reversed polarity voltage, surges and spikes according to MIL-STD-1275

- Electromagnetic Compatibility: EMI/RFI protected CE Marked

General Specifications

| Duct Mounted SafEye Model | 202FD | 301FD | 302FD |

| Gas Detecting Range | 6.6 – 23ft | 2 – 11.5ft | 9.9 – 49.5ft |

| Detected Gases | Simultaneous detection of C1-C8 flammable gases | ||

| Response Time | 1 second | 2 seconds | |

| Immunity to False Alarm | Not influenced by solar radiation, hydrocarbon flames, other external IR radiation sources, high airflows and high loaded streams | ||

| Spectral Response | 3.0-4.0 μm | ||

| Sensitivity Range | 0-2.5 LEL.m Standard 0-1 LEL.m by dip-switch setting |

||

| Displacement/Misalignment Tolerance | 2º | ||

| Drift | Long-term ±5% of full scale | ||

| Temperature Range | -40˚F (-40˚C) to 131˚F (55˚C) for Series 200 -40˚F (-40˚C) to 158˚F (70˚C) for Series 300 |

||

Mechanical Specifications

| Dimensions | 5.2″ (132mm) x 5.2″ (132mm) x max. 4.7″ (120mm) |

| Weight | Aluminium Enclosure – Detector: max 8.8 lb (4 kg) Source: max 10.8 lb (4.9 kg) Stainless Steel Enclosure – Detector: max 14.3 lb (6.5 kg) Source: max 16.7 lb (7.6 kg) |

| Mechanical Design | The standard detector housing is heavy-duty, copper-free (less than 1%) Aluminium. The housing is finished in white epoxy enamel and is also available in 316 Stainless Steel* upon request. *Carries an additional charge. |

| Environmental Standards | Meets MIL-STD-810C for Humidity, Salt & Fog, Vibration, Mechanical shock, High Temp, Low Temp |

| Water and Dust Tight | IP66 and 67 per En60529 NEMA 250 6P |

| Hazardous Area Approvals | ATEX SIRA 00ATEX 1161, EX II 2G EEx d IIB + H2 T5 (70˚C), T6 (55˚C) SIRA 00ATEX 1165, EX II 2G EEx de IIB + H2 T5 (70˚C), T6 (55˚C) UL UL No. – E209870, Class I Groups C and D Hazardous Location FM (300 Series only) Class I, Division 1, Groups B, C and D, Dust Ignition proof for Class II, Division 1, Groups E, F and G |

Crowcon Duct Mounted Gas Detectors

Tried & Tested

In an offshore installation in the North Sea, the SafEye was tested over six winter months which included weather conditions such as very dense fog, snow and rain. The gas detector remained fully operational at all times.

The SafEye range is built for reliability and continued operation under all types of extreme environmental conditions.

Typical applications include Offshore Oil & Gas Exploration Oil Rigs and FPSOs; Onshore Oil & Gas Terminals; Storage Farms and Filling Stations; Petrochemical and Chemical Industries; Power Utilities and Turbines areas; Waste Processing and Treatment; Transportation Terminals; Automotive, Painting, Printing, Pharmaceutical Industries and many more.

Hazardous Area Equipment

Visit hazardous area gas detectors for explosion and flameproof gas monitoring and detection instruments with certification for potentially explosive atmospheres, including Zone 1 and Zone 2 (according to ATEX and IECEx) and Class/Division categories (according to North American standards).

T&D provide competitive prices and delivery for all Crowcon Gas Detectors, including the Crowcon Open Path Gas Detectors.

:arrow: Did you know? Crowcon fixed gas detectors protect plant; portable gas detectors protect people.

T&D Sales Team are Certificated by Crowcon to support the specification and supply of their flammable and toxic gas detectors. Additionally, T&D are CompEx Certificated and competent in understanding hazardous area classifications and site requirements for the sale of explosion and flameproof equipment.

Flame, Heat, Gas Detectors & Detection Systems

![]()

Hazardous area industries including offshore oil/gas platforms and FPSOs, onshore oil refineries, processing plants, pipelines, storage farms and LPG/LNG plants all utilise or produce a wide range of hazardous flammable liquids and gases that can be detected using correctly specified flame and gas detectors.

Detecting toxic and flammable gases requires the detectors to be classified and certified according to the specific IECEx or ATEX standard – we distribute flame and fire detectors manufactured by Spectrex to operate in the harshest environmental conditions including self-contained stand-alone devices designed for direct connection to control and alarm systems or automatic fire extinguishing systems.

Our range of Hazardous Area Fire & Gas Detection System products also includes Explosion Proof Warning Systems & Hazardous Area Lighting – comprehensive range of intrinsically safe, flameproof and explosion proof alarm sounders, sirens, bells and horns, loudspeakers and beacons.

♦ LV Power Products | Junction Boxes & Enclosures ATEX | Plugs ATEX | Control Stations ATEX | Isolators ATEX

Thorne & Derrick | Detecting Flame | Heat | Gas