Extractive Gas Analysers & Analysis Measurement | Zone 1 Zone 2 Hazardous Areas

Gas Analysis & Measurement

Extractive Gas Analysers

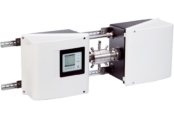

Extractive gas analysers can be used in a large number of applications, including those within certified hazardous areas.

The extractive measurement technology extracts a partial gas flow from the gas duct, conditions the extracted gas and feeds it to an analyser module under constant conditions.

Gas detection and analysis equipment manufactured by SICK, offers perfectly tailored technology from gas sampling and conditioning right through to the numerous analyser modules.

SICK Level Sensors – Continuous Level Measurement & Point Level Measurement

SICK eXTRACTIVE Gas Analyser rANGE

SIDOR

- Detector with high long-term stability

- Paramagnetic or electrochemical O2 measurement

- Automated adjustment with component-free ambient air

- Immune to contamination

S700

- 5 different measurement principles available

- More than 60 measuring components to choose from

- 3 different housing variants for different fields of application

- Up to 3 analyser modules in a single housing

MERCEM300Z

- Accurate measurement of “total mercury” directly in a thermal converter (patented)

- Measuring operation without using consumables

- Practically maintenance-free gas sampling using an ejector pump – no moving parts

- Integrated adjustment cell for automated drift checking

- Automated adjustment of the entire measuring system with a built-in test gas generator (optional)

- Completely modular system design

GMS800

- 6 different analyser modules: DEFOR (NDUV, UVRAS), MULTOR (NDIR), OXOR-E (electrochemical O2), OXOR-P (paramagnetic O2), THERMOR (TC), and UNOR (NDIR)

- 4 different types of enclosures

- Gas module with sample gas pump and/or control sensors

- New enclosure type for easy and quick integration in analyzer systems

- Remote diagnosis via Ethernet with SOPAS ET software

GMS800 FIDOR

- Standard 19” enclosure for easy integration into all industry-typical systems

- Space-saving wall housing (stand-alone)

- Nearly maintenance free ejector pump delivers sample gas to the analyser

- Integrated catalytic converter (option) provides very clean zero gas

- Automatic regulation and compensation of process pressure fluctuations

- Protective filter at sample gas inlet

- High degree of linearity (≤ 2 %) for very low and high measuring ranges

MCS300P

- Simultaneous measurement of up to 6 components

- Process cells up to 60 bar and 200 °C

- Automated sample point switching

- Integrated adjustment unit (optional)

- Safety devices for measurement of toxic or flammable mixtures

- Extended operation via PC and SOPAS ET software

- Flexible I/O module system

GME700

- High selectivity due to high spectral resolution

- No calibration required

- No moving parts: minimal wear and tear

- Heated multipath measurement cell

- Hot-wet measurement technology

SICK Gas Analysers provide accurate measurement and monitoring of gases on Flue Gas Desulfurization (FGD) projects. Image : GE.

GAS – MEASURE, ANALYSE & DETECT

To complement and support SICK Gas Analysers & Transmitters, T&D also distribute Crowcon Gas Detection Equipment to enable the safe detection of flammable and toxic gases in industrial and hazardous area industries.