Fisher Baumann 83000 Valve – Sanitary Control Valves

Fisher Baumann 83000 Sanitary Control Valves

Fisher Baumann 83000 valve is a sanitary control valve that is suitable for the control of high purity fluids or gaseous media.

83000 sanitary control valves have a low-friction-force amplification mechanism, comprised of a roller bearing linkage, produces high-positioning resolution suitable for direct operation from remote I/P signal converters.

Fisher Baumann 83000 valve is available for lab flow rates as low as 0.001 litres per minute (l/m) with a Cv range of 0.00001 to 1.02.

83000 valve has a unique packless design and can be used in CIP (Clean-in-Place) and SIP (Sanitize-in-Place) procedures.

Fisher Baumann 83000 Valve – Product Features

- Compact and light-weight design reduces installed piping costs.

- NPS 1/2 tri-clamp end connections standard with optional welded connections.

- Electropolished wetted interior finished to ≤ 30 Ra microinch (≤ 20 Ra microinch optional).

- Self-draining designed for Clean-in-Place (CIP) and Sanitize-in-Place (SIP).

- Closure diaphragm is polished 316 stainless steel; Quick-Disconnect bonnet aids closure diaphragm replacement.

- Epoxy powder-coated actuator with stainless steel fasteners for maximum corrosion resistance.

- Multi-spring field-reversible actuators with reduced deadband permits direct operation from remote signal devices.

- Fisher® FIELDVUETM digital valve controller for remote calibration and diagnostics in facilities utilizing the PlantWebTM.

- Elastomer seals meet FDA and USP CLVI requirements

FISHER BAUMANN 83000 VALVE

PRODUCT Specification

| Sanitary Control Valve Size | NPS 1/2 |

| Connections | Tri-Clamp or optional welding ends |

| Valve Body Material | 316L SS |

| Valve Body Rating | 275 psig CWP |

| Trim Material | Polished 316 SS, or N10276 Nickel Alloy |

| Trim Characteristic | Modified Equal % |

| Seat Leakage | ANSI/FCI 70-2 Class IV |

| Cv Ratings | 0.01 to 0.70 |

| Bonnet Type | Standard bolted |

| Packing Material | Packless |

| Temperature Range | -18°C to 149°C (0ºF to 300°F) |

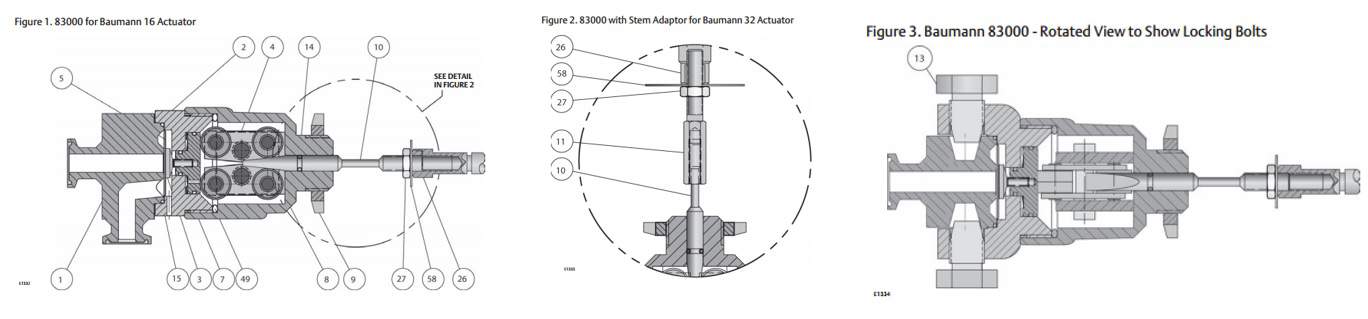

Fisher Baumann 83000 Valve – Sanitary Control Valves – Materials of Construction

Fisher Baumann 83000 Valve – Sanitary Control Valves

| Key Number | Description | Material |

| 1 | Valve Body | ASME A479 S31600/S31603 |

| 2 | Bonnet Yoke | S30400 SST |

| 3 | Piston Subassembly | S30300 SST and FKM (Fluorocarbon) |

| 4 | Bearing Cartridge Subassembly | Stainless Steel and PTFE (Polytetrafluoroethylene) |

| 5 | Closure Diaphragm | S31600 SST, standard / N10276 Nickel Alloy, optional |

| 7 | Wave Spring | S17700 SST |

| 8 | Bonnet | ASTM A743 CF8 |

| 9 | Drive Nut, Yoke | S30400 SST |

| 10 | Plunger | ASTM A276 S31600 Condition A |

| 11 | Actuator Stem Adapter for Baumann 32 | A582 S30300 Stainless Steel |

| 13 | Locking Bolt | S21800 SST |

| 14 | O-Ring, Plunger | FKM (Fluorocarbon) |

| 15 | O-Ring, Body | EPDM |

| 27 | Jam Nut, Baumann 16 Actuator | Stainless Steel (18-8 SST) |

| Jam Nut, Baumann 16 Actuator | S30400 SST | |

| 49 | O-Ring | FKM (Fluorocarbon) |

| 58 | Travel Indicator Disk | ASTM A240 S30400 |

See how Fisher Control Valves provide safe, efficient and intuitive flow control.

Sanitary Control Valves

Sanitary control valves, with valve bodies manufactured from 316 stainless steel, are specified throughout HVAC, life sciences, pharmaceutical, food and beverage, cosmetics, speciality chemical and R&D industries to provide fluid flow with minimised pressure drop.

The sales of valves to satisfy the stringent sanitation requirements of the pharmaceutical, food and other life science industries in 2015 will exceed $3.4 billion worldwide. This is the last forecast in Industrial Valves World Market published by the McIlvaine Company.

Fisher Rotary Valves: Flow Control For Power, Oil, Gas & Refining Pipelines.

➡ Did you know? Fisher was founded in 1880 by William Fisher. Today, Fisher valves are used throughout oil and gas, petrochemical, refining, power and paper industries – the company is now a subsidiary of the Emerson Process Industrial Group.