Spartan Linear Generation II | Performance Upgrades Explained

Published 16 Mar 2022

Spartan Linear Generation II Lighting By Raytec

Hazardous Area Lighting

Spartan Linear Generation II By Raytec

UK Stocks | International Delivery | Zone 1 (21) & Zone 2 (22) Hazardous Area Light Fittings From Stock

Raytec have recently launched their Linear Generation II – an upgrade on the original SPARTAN Linear where they’ve been able to increase power, performance, and durability across the Linear range. The upgrade has a host of new features and variants to suit all your hazardous area lighting requirements in a range of different applications.

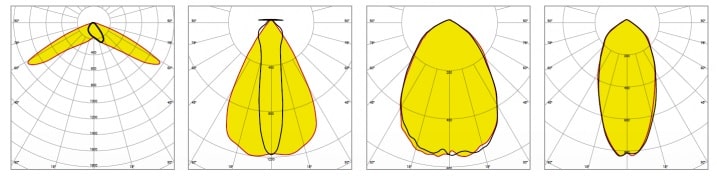

The Spartan Linear is now delivering up to 7,000lm / 142 lumens per watt, and for the first time is available with a choice of beam angles (see below) which are ideal for a wide range of applications.

Choice of Optics – More beam angles = fewer luminaires per installation

Performance Upgrades?

What Do They Really Mean?

While this all sounds great on paper, what do these performance upgrades mean in the real world? In this article, Raytec use their award-winning lighting design service to demonstrate the improvements; We’ll look at three different scenarios and compare the existing Linear (Gen 1) products side-by-side with the new Linear Generation II (Gen II).

Utilise Fewer Luminaires

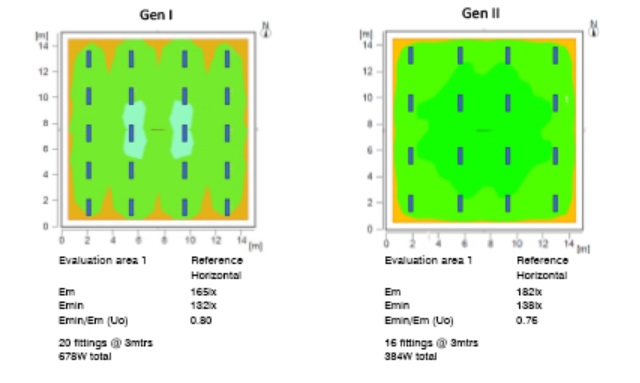

The first design we’ll look at is a basic 14x14m square internal room, where we’ll be aiming to achieve an average of 150lx.

The Gen I design (left) requires an installation of 20 luminaires to achieve the target light levels, with the result coming out at 165lx. If we compare this to the Gen II design (right), for the same installation we only need 16 luminaires – and despite using fewer fittings, there’s actually more light on the ground, with an average of 182 lux.

In addition to the improved performance, there’ll also be a significant reduction in energy consumption – a 45% saving, largely thanks to a new, more efficient driver. With fewer luminaires required, there’s also a capital saving to be made of around 17.

For larger installations, the extent of these savings will grow exponentially and help end-users to significantly reduce both their initial outlay and ongoing running costs.

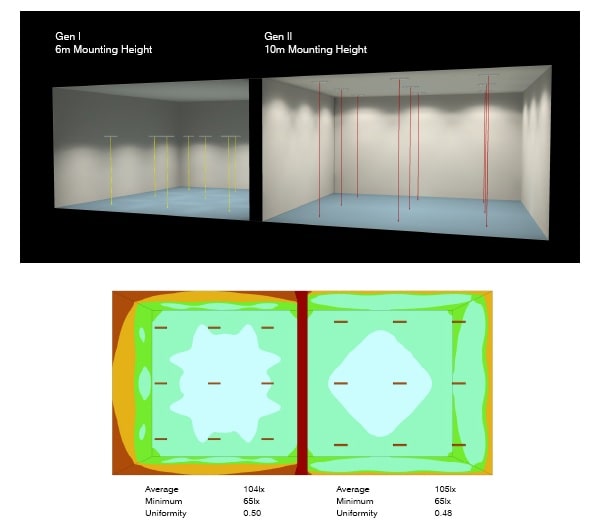

Mount Higher

In the next example, we’ll look at the impact of Linear Gen II’s improved performance has on mounting heights. Below, the Gen I design (left) has the luminaires mounted at 6m, whereas the Gen II design (right) which has the mounting height increased to 10m.

Despite being mounted 4m higher, Linear Gen II is delivering almost identical results to the Gen I luminaires mounted at 6m.

In short, Linear’s increase in power means it’s now possible to significantly increase the height in which the luminaire is mounted. It also brings the performance of the luminaire into the territory of low-bay style fittings, but with the advantage of being far more cost effective, and being available with emergency battery back-up. This brings lots of new opportunities to end-users.

Greater Flexibility

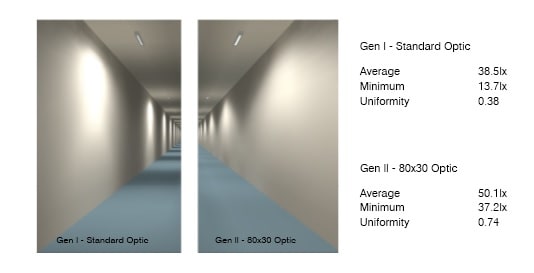

Linear is now available with a choice of different beam patterns thanks to a range of secondary optics. While this is beneficial to a host of applications, the new 80×30 beam angle is particularly beneficial for aisle or walkway applications, offering big improvements over the single beam angle available with the existing Linear;

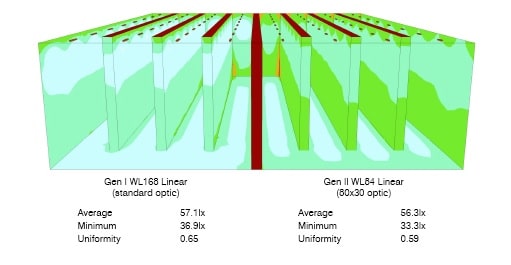

Gen I & Gen II Optic Comparison

In the Gen I design (left) the results are noticeably patchy. A lot of the light is being wasted against the side wall, leaving dark areas along the floor as you continue down the corridor. If we compare that with the same design using the new Linear Gen II (utilising the 80×30 optic), we can see that the floor has a much more even light distribution with far less light wasted against the wall.

This is reflected by a big improvement in the average and minimum lux levels, as well as a far better uniformity rating when using Linear Gen II and it’s 80×30 beam angle.

Use Smaller Luminaires

In some scenarios, Linear’s performance upgrade and new optics can even allow end-users to utilise a smaller sized variant.

Below are two identical scenarios; a warehouse installation where the lighting goal is to illuminate the aisles between the racking. On the left is a design using a Linear WL168 Gen I luminaire (designed as a direct replacement for a traditional 4ft/2x36W fluorescent), and on the right is the same design using Gen II Linear, but a smaller SPARTAN WL84 fitting (designed to replace a traditional 2ft/2x18W fluorescent).

While the larger Gen I fitting has a greater light output on paper, within this application we can see a lot of the light is being wasted against the racking either side of the aisle (especially towards the top of the racking). In contrast, looking at the Gen II (right), the beauty of the new optics means that more of the light can be targeted straight down to the ground, between the aisle, exactly where it’s needed.

The upshot of this is, despite using a smaller sized Linear on the Gen II design, both are delivering the same performance on the ground. Both solutions deliver an average of 57 lux from the same 12-meter mounting height.

While end-users looking to ATEX retrofit existing fluorescents may still have to consider existing infrastructure, such as cabling and bracketry, the ability to use a smaller luminaire could be particularly beneficial for new installations. Utilising a smaller Linear will again help to reduce the initial capital outlay as well as ongoing running costs.

As we’ve demonstrated, the performance upgrade to Linear Generation II brings significant benefits when it comes to real-world applications. It provides end users with greater levels of flexibility in terms of the types of applications and the areas where the luminaire can be used effectively, all while helping to reduce costs and energy consumption.

How Can T&D Help?

Lighting Designs & Surveys

Thorne & Derrick hold large UK stocks of ATEX light fittings, ensuring fast overnight delivery to your plant.

Using latest software our FREE Lighting Design Service supports the upgrade from fluorescent to LED lighting focussed on maximised light output, optimised energy consumption with reliable and safe certification for explosion protection concepts in Zone 1 and Zone 2 hazardous area zones and workplaces.

Contact our technical sales team today who will assist with all your winter lighting requirements.

Raytec SPARTAN

Thorne & Derrick International, based in the UK, are Preferred Distributors and Stockists for the Raytec SPARTAN range of ATEX lighting using LED technology for the illumination of hazardous area locations and potentially explosive atmospheres.

SPARTAN is a full range of Ex LED luminaires and lighting approved for all ATEX and IEC Ex Zone 1 and Zone 2 hazardous area environments, including UL /CSA C1D2 installations. The hazardous area lighting products are designed for the most extreme environments – Flood, Linear, Bulkhead, Bay and Crane luminaires with emergency and industrial lighting versions are also available from Thorne & Derrick International.

EXPERTS IN EQUIPMENT FOR EXPLOSIVE ATMOSPHERES

leaders in ATEX Innovation To The Hazardous Area Industries

Thorne & Derrick are leaders in the development and distribution of Product Innovations that deliver significant improvements to clients plant, people and operational safety in the explosive atmosphere industries.

Your proactive problem solvers experienced in succession planning for the replacement of obsolete, non-conformant and legacy equipment in hazardous areas.

Your first-choice provider of innovative and competitive solutions to ensure ATEX & IECEx Compliance for Hazardous Area Electrical, HVAC & Process Instrumentation Equipment to UK and international projects.

Control Panels | Plugs | Isolators | Enclosures & Junction Boxes | Lighting | Control Stations | Motor Starters | Heat Trace | Gas Detection | Flame Detection | Process Instrumentation | Process Heating | Ventilation Fans | Security Access Control | ATEX Enclosures