Wireless Technologies Take Personnel Safety In The Process Industries To A New Level

Published 21 Oct 2019

- By Chris Dodds : estimated reading time 18 minutes

T&D, Specialist Distributors of ATEX Certified Hazardous Area Equipment

Introduction

In modern times the Process Industries have implemented many strategies to improve the operational safety of plants to protect personnel and the surrounding environment, to the extent that accidents are thankfully few and far between.

However even within the relatively safe environments of today’s modern process plant the need to account for all personnel in the event of a dangerous incident and get them safely off the plant as quickly as possible is still of paramount importance.

In the event of an emergency alarm personnel are required to go to designated areas, often called “Muster Points” and until recent times the method to account for all personnel has been implemented by signing in and out of plant areas using a register or “T Cards.”

Manual methods were enhanced by the use of swipe cards or non contact close proximity card readers using the first generation of RFID technology. These methods are just electronic versions of the “T Card” or “Register” system requiring personnel to manually sign in or out of plant areas or at the “Muster Point”.

These basic methods have a major disadvantage as they require the person to remember to sign or swipe in and out of plant areas and are time consuming to tally that all the personnel that have assembled at the different “Muster Points” equates to the total number of people on the entire plant.

Not having accounted for the correct amount of people poses a nightmare scenario, especially in the event of a real emergency where emergency crews are tasked with locating the missing personnel. In real life emergencies minutes can mean the difference between life and death.

It is a common fact that on a plant with several hundred people spread over large areas manual mustering can take up to an hour which is far from satisfactory, considering these statistics have been established under ideal conditions where staff are aware that there will be a practice of the emergency evacuation procedures.

RFID Technologies

To overcome the problem of remembering to sign or swipe in and out of plant and to speed up the whole Mustering process modern RFID technology can be utilised. There are essentially three type of RFID technology available;

Figure 1. Passive RFID Tags

Passive: This type of tag typically works on LF (Low Frequency) 125KHz, HF (High Frequency) 13.56MHz or UHF (Ultra High Frequency) 868MHz and has no internal battery power source but induces current from the RF field to power the tiny radio transmitter built into the Tag.

These tags only transmit their identity when being read (in the RF field of a Reader) and do not have any other functions as they are effectively a wireless barcode. A point to note is that there are some versions that allow writing to the tag as well.

The typical read range of a LF or HF tag is up to a maximum a few tens of centimetres depending on the antennas and RF power used. The new EPC Class 1 GEN2 standard UHF tags can have a read range of up to 6 metres. The advantages of these tags are that they require no maintenance and are low cost.

Assisted Passive: This type of tag still is still a proprietary technology in that no international standard exists at the moment, although there are companies that are working towards one.

The tag has a small coin cell type battery which is used to help power the transmitter and thus read ranges of up to 50 metres line of sight may be achieved although in practice many do not perform anywhere near this range.

The tag still has very limited intelligence and offers no other functionality other than transmitting it’s ID. The cost is of course more than passive devices and once the battery has expired the tag must be replaced as the batteries are not replaceable.

Active: This type of tag is available in many variants and standards and typical frequencies they operate on are 868 MHz, 2.4 GHz or 3 to 6 GHz.

The power source is a much more substantial battery, typically a Lithium Ion primary cell which means the tag can incorporate a powerful microprocessor to provide many other intelligent functions such as motion detection, temperature measurement and emergency call button features.

The extra power for the radio transmitter means that the tag can transmit data up to 200 metres line of sight to a receiver at predetermined intervals or in the case of certain tags like the Extronics iTAG100 they also contain a LF 125KHz receiver so that the tag can be triggered to transmit a beacon to confirm its presence when it is in the field of a suitable reader called an Exciter.

Figure 2. iTAG100 Active WiFi & LF RFID Tag

Figure 3. iCITE100 LF Exciter

The read range of the tag in this case is up to 6 metres from the Exciter. These tags have to have the batteries replaced at certain intervals determined by the number of transmissions they make and of course they cost more than the other variants due to the enhanced features.

Battery life for these types of tags us up to 4 years but can be much less when making very frequent transmissions.

100% Read Reliability is Critical in a Mustering System Application

When utilising an RFID technology for Mustering applications the most important characteristic is the read reliability. It makes no sense to deploy a system where the read reliability is not 100% due to the fact this will mean that a person will be reported missing when they are not.

Passive and assisted passive tags do not have the read reliability to be considered for an Automatic Mustering System. The reason the read reliability is not 100% is due to the fact that the available power to transmit the RF signal is not sufficient to penetrate the human body due to the fact that the average adult body contains more than 70% water which attenuates the signal.

This is a major problem considering the tag must be worn by a person. There are possible solutions to this such as fitting a tag to the wearers Personnel Protection Equipment such as a hard hat and then fitting readers in ceilings above the choke point.

This is not an optimum solution and is a work around and even with such an approach in practice they still do not have a high enough read reliability.

Active tags on the other hand have much more powerful radio transmitters that allow the tag transmission to pass through the human body and can be programmed to send more than one transmission when in the RF field of a reader thereby achieving the near 100% reliability that is required for an Automatic Mustering System.

Mustering Stations and Entry/Exit into Zones

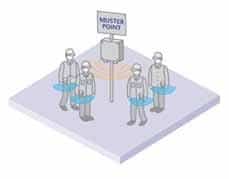

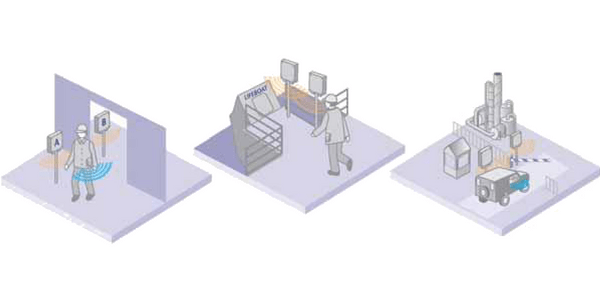

A Mustering Station usually consists of one or more readers at strategic locations around a plant where personnel go in the event of an emergency evacuation alarm.

Using two readers or antennas it is possible to determine the direction of movement of the person wearing the tag, so it is possible to count the numbers of people entering into certain areas or zones of the plant such as the site entrance and exit. Other benefits of this technology enable counting of people into life boats or across bridges etc on offshore platforms.

Figure 4. Muster Station using LF Exciter

Figure 5. Entrance and Exit Location Tracking using LF Exciters

Automatic Mustering Does not Solve all Problems

Once the Muster process is complete and it has been established that everyone is present then all is well. However it is a known fact that if an incident of some sort has occurred such as a fire or chemical spillage and someone is still unaccounted for the emergency services must try and find them.

So where does one search for the missing personnel after a muster procedure has identified they are missing?

Overcoming this problem is now a key objective for Health and Safety Managers in the Process Industries. The most obvious solution is to install large numbers of readers around the plant so that the last known location is determined by the last reader the person walked by.

This technique is often acceptable in mines where tunnels or sections of tunnels would be the likely location where a missing person/s could be found due to the fact they can only follow the tunnel.

On a process plant such as a refinery or chemical plant this method is not practical as there would have to be an uneconomical number of readers positioned across the site, as people can walk in any direction. The level of accuracy would also be poor and at best a zone or area of the plant could be determined.

The desire by plant operators to be able to track their work force and know their exact location to within a few metres accuracy is becoming more compelling due to increasing demand in legislation that is designed to protect the welfare of workers in industry.

Being able to pin point the location of a worker who has not made it to the “Muster Points” means emergency services can be deployed to the exact location and undertake a rescue in the fastest time possible. Using this technology minimises resources and limits the exposure of the rescue team to any dangers on site and increases the chances of a successful rescue.

Where are the Missing Persons?

Wireless technologies that have been in existence for the past decade are now well developed and mature enough to overcome the last hurdle in emergency evacuation procedures.

There are several Real Time Location Tracking technologies that can be applied based on one or more location principle, each with their own key benefits and disadvantages.

Be it proprietary hardware, will only work outdoors or indoors, accuracy may be affected by multi-path RF reflections or that the cost of the infrastructure is prohibitive. As is often the case, no one technology can resolve the problem in its entirety.

Real Time Location Principles

The basic principles used by most Real Time Location Systems (RTLS) are Received Signal Strength Indication (RSSI) and Time Difference of Arrival (TDOA).

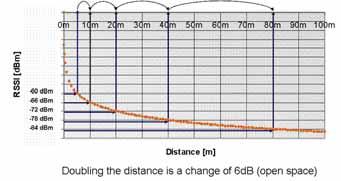

Received Signal Strength Indication is the strength of the signal from a transmitting device as measured by a receiver.

The RSSI value of a transmitter is measured by a receiver such as a WiFi Access Point and location is derived from the relationship of radio signal strength to distance. If the RSSI is measured by at least three receivers the position is calculated based upon the intersection of those distances from the receivers installed at known locations.

As the relationship is Non Linear the RSSI principle can only practically be used for shorter distances.

Figure 6. Location of tag using RSSI principle

The accuracy can also be affected by RF multipath, due to reflections from hard surfaces such as metallic structures.

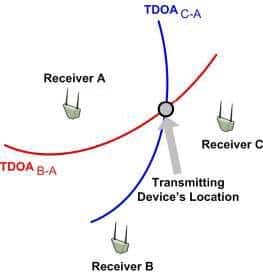

Another very common location principle is Time Difference Of Arrival (TDOA) which is the process of locating an object by accurately computing the time it takes for a transmitted radio signal (speed of light) to travel to a receiver at a known location.

The Time Of Arrival (TOA) of a transmitting devices signal is measured by at least three time synchronised receivers. The transmitting device’s position is determined by calculating the TDOA of the signal at these receivers and uses this information for triangulation.

Figure 7. Relationship of RSSI to distance

When a transmitting device sends a signal, it arrives at slightly different times at two spatially separated receivers. For given locations of the two receivers, a whole series of transmitter device locations would give the same measurement of TDOA.

Given two receiver locations and a known TDOA, the range of possible transmitting device locations creates a hyperbola. A receiver at a third location would provide a second TDOA measurement and therefore locate the device on a second hyperbola.

Assume an unknown transmitting device X and known receivers A, B and C. The TDOA between each pair of receivers is calculated as follows: TDOA(B-A) = |TB – TA| TDOA(C-A )= |TC – TA|

The hyperbolic plots representing all possible difference of distances of the transmitting device from each pair of receivers. The intersection of two or more hyperbolae defines the position.

The TDOA principle is much more tolerant to RF multipath problems that are experienced in the Process Industries due to the fact advanced algorithms in the location engine can be applied to this measurement principle.

Another principle that is worth mentioning is Angle of Arrival (AOA) whereby the location is determined by measuring the angle that a transmitted radio signal is measured at a receiver at a known location.

The method is not commonly used due to the fact that it does not really offer any tangible benefits over the TDOA and RSSI principles due to requiring special antennas and the overall hardware costs generally being higher.

Figure 8. Hyperbolic plots representing possible difference of distances

Real Time Location Technologies

One location technology we are all familiar with in our everyday lives is GPS which in outdoor areas will provide location accuracy to sub 10 metres by receiving signals from at least 3 satellites and using Time Difference Of Arrival (TDOA) algorithms to calculate the position of the receiver.

This technology does not work indoors as the RF signal is not powerful enough to penetrate though buildings and needs a wireless network of some sort to update the location tracking software with the last location due to the fact the GPS satellites only transmit and have no receive mode.

Figure 9. Location using the Global Positioning System

New products are now becoming available such as a mobile telephone with a GPS receiver, dead man sensor and emergency call button.

Figure 10. Ex Mobile Telephones with GPS

Another familiar technology is the WLAN or WiFi network that most of us have at home or in the office.

If there are a number of access points providing blanket coverage in cells across a site it is possible to use the Received Signal Strength Indication (RSSI) to calculate the position of the tag, again by using a triangulation calculation algorithm much like that used by GPS except based on signal strength.

This principle of location works indoors with an accuracy of sub 5 metres as well as outdoors but with much less accuracy.

The reason for this being the fact that the relationship between WiFi signal strength and distance becomes exponential after about 50 metres which means the cost of installing a high density matrix of access points would become prohibitive.

Such a high density matrix is much more than is needed for most mobile computing applications, where an access point every 100 to 150 metres will more often than not provide adequate outdoor connectivity and throughput.

Some vendors have also developed their own receiver that has a TDOA (Time Difference of Arrival) function as well and will work outdoors up to 200 metres with sub 5 metre accuracy.

The only downside with this is the proprietary infrastructure, which unlike a WiFi network cannot be used for any other purpose meaning the “Return On Investment” (ROI) takes much longer than a WiFi based location system.

Figure 11. Location using WiFi Networks

Figure 12. iWAP103 Access Point Enclosure System

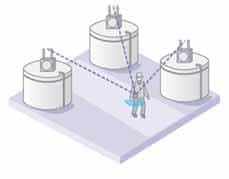

Some companies are demanding location accuracy of sub 5 metres for use in a very dense metal environments such as a processing unit on a refinery where it is impossible to visually spot someone from more than a few metres away.

In a 100 x 50 x 50 metre process unit consisting of metal pipes, vessels, walkways and stairs the only technology that can provide a solution with this degree of accuracy is Ultra Wide Band (UWB).

This location technology (similar in principle to radar) can perform to less than 1 metre accuracy, even better is some cases. The other advantage of this technology is that it is possible to calculate location in 3D with suitably placed location receivers.

The method of location calculation is both TDOA and also AOA (Angle of Arrival) However the density of the receiver infrastructure required makes this technology prohibitive to use over a complete site.

Providing an economical solution to mustering is now possible and practical to implement but what solution can provide economical location and tracking of people across a complete facility?

It is hard to imagine industry investing huge sums of money to locate personnel down to sub 1 metre accuracy when there is no need and especially as a very large investment in infrastructure that would be required.

It is a common convention now that WiFi is a good investment for industry and can improve working practices, overall efficiency and safety. The Process Industries are now starting to install blanket WiFi coverage in their plants for data and voice applications.

Using the WiFi network as the primary means of Location Tracking makes sense as it has already been installed for other reasons so the ROI is greatly improved.

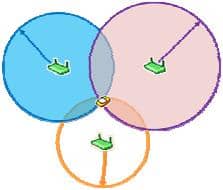

New tags are being developed that combine GPS and UWB technologies with WiFi and LFR provide an ultimate solution for plant wide location tracking.

Where the level of location accuracy is not adequate by using WiFi alone, such as in large open outdoor areas with a low density of installed Access Points, the GPS mode would be used.

In places where a sub 1 metre accuracy is required, such as in a processing unit where the mass of pipes, vessels and walkways make it necessary to have “pin point” location accuracy, UWB location receivers would be installed. The UWB transmitter in the Tag would then be used.

The most practical and cost effective approach to choosing an RTLS (Real Time Location System) is to adopt a granular approach to the location accuracy and to utilise the most appropriate location technology for the level of accuracy required for that particular area of plant which keeps the costs of the complete RTLS infrastructure to a minimum.

Figure 13. GPS, LFR & WiFi Tag Counting

Enhanced Safety Features

With active tags having a powerful processor it is possible to add advanced safety features to the location tracking functions offering a compelling solution to worker safety. A sensitive motion sensor is used to monitor for “man down” and will raise an alarm if not motion is detected for a defined period.

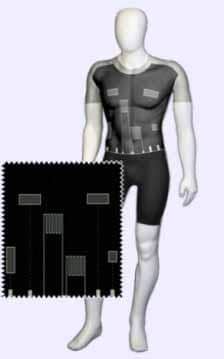

A local button on the Tag allows the worker to call for emergency assistance by raising an emergency call. Technology also exists such as the SmartLife® Technology wearable life signs monitor whereby the workers vital life signs such as ECG (Electro Cardiography) Respiratory Function, heart rate and body temperature are monitored continuously so that in the event of any abnormal measurements an alarm can be raised.

This new technology offers the possibility of the true “lone worker” whereby a “buddy” is not required as the lone workers safety is continuously monitored from a central location. The enhanced worker protection as well as dramatic cost savings offer a compelling argument for investment in such Automatic Mustering and Personnel Location systems.

Figure 14. Smartlife vest for monitoring vital life signs

More Reading

- Extronics iCAM502 – The Hazardous Area ATEX Camera

- Winterisation – Electrical Heating Mitigation Measures To Counteract Freezing Temperatures

ELECTRICAL & PROCESS INSTRUMENTATION EQUIPMENT

FOR EXPLOSIVE ATMOSPHERES

Thorne & Derrick are Specialist Distributors of Hazardous Area & Explosion Proof Equipment with IECEx & ATEX Certifications to the onshore and offshore oil, gas, petrochemicals and process industries.

Key Product Categories: Control Panels | Plugs & Sockets | Isolators | Enclosures & Junction Boxes | Lighting | Control Stations | Motor Starters | Heat Trace Cables & Systems | Gas Detection & Detectors | Fire Detection & Detectors | Heat Detectors | Electrical Heating & Heaters

Trace Heating | System Design & Supply