Flanged Immersion Heaters For Oil | ATEX Hazardous Areas

Chromalox ATEX Flanged Immersion Heaters For Oil

ATEX Flanged Immersion Heaters For Oil

Chromalox

This range of flanged immersion heaters, manufactured by Chromalox, are suitable for oil heating applications within ATEX certified hazardous areas. The term oil, in this case, covers a variety of viscous fluids which require a particular watt density in order to avoid damage.

Flanged immersion heaters for oil offer a watts density between 1.2 and 3.9 W/cm² and feature sheathed removable heating elements, but “monotubular” type, set in pockets, to allow the sheath to be removed without emptying the tank. This is particularly useful for large tanks or processes where removing the complete immersion heater would mean the oil would need to be transferred to another tank, leading to unnecessary downtime.

Standard products in this range have PN16 or 150 Ibs ANSI flange, but can be supplied on request, with every standard flanges up to 2500 Ibs.

Chromalox Flanged Immersion Heaters – Features

- ATEX Certifications for Hazardous Locations

- IEC/CE Certification

- IP55, IP66, & IP42 ingress protection ratings

- DN or ANSI flange connections

- 400V 3ph

- Gland Plates

- Sensor well for thermostat, sensor or cutout

- 316 Stainless or Incoloy 800 heating sheath

- Removable heating elements

- Terminal housing standoffs

- Contact our expert sales team for more information

- Also Immersion Heaters for Heating Water

Flanged Immersion Heaters

product range

chromalox TRHGB 080 / 100

TRHGB 080 and TRHGB 100 are flameproof immersion heaters with metric flanges, used for medium viscosity oil heating within hazardous areas.

- ATEX Certification: ATEX II 2 G – Ex d II C

- Temperature Class: T1 to T6

- PN16 DN80 or DN100 mild steel flange

- AISI 321 sheathed elements

- Watts Density : 2 W/cm²

- Built in pocket for optional sensor, thermostat, or cutout

- Stood off painted, IP55 mild steel terminal enclosure, supplied with 2 cable glands

- Voltage 400 V / 3ph

Immersion Heater Specification

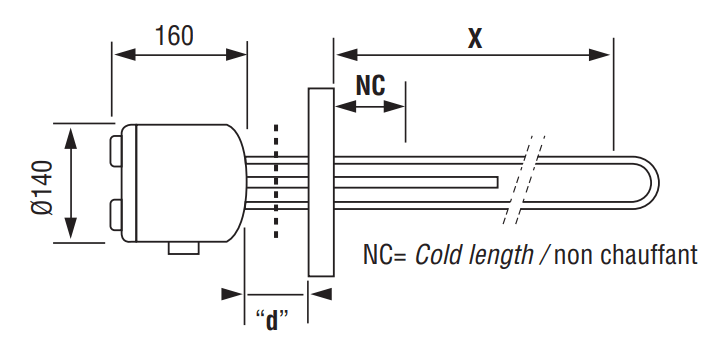

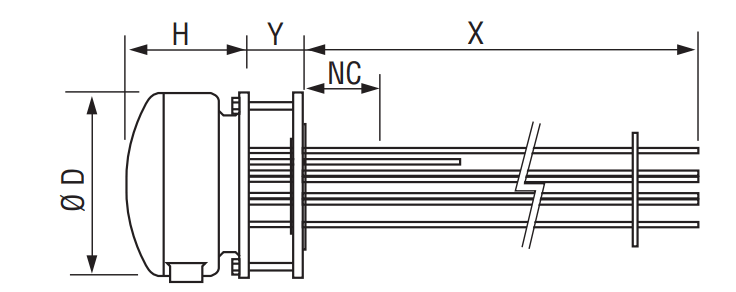

TRHGB 080 | TRHGB 100 Dimensions

Immersion Heater Product Guide

On request:

• Flanges according to standard PN10 / 20 / 25 / 40 / or 50

• Variation with Watts density 1.2 W / sq.cm for heavy oils, or 4.0 W / sq.cm for light oils

• Other sheath materials

➡ Add your required temperature class (T1, T2, T3, T4, T5, or T6) at the end of the order code.

| Chromalox Order Codes |

Immersion Heater Specification | |||

| Flange Size | Output | Length ‘X’ |

Cold ‘NC’ |

|

| DN80 | DN100 | |||

| TRHGB080A002I02 | TRHGB100A002I02 | 2 kW | 465 mm | 100 mm |

| TRHGB080A003I02 | TRHGB100A003I02 | 3 kW | 630 mm | |

| TRHGB080A004I02 | TRHGB100A004I02 | 4 kW | 795 mm | |

| TRHGB080A006I02 | TRHGB100A006I02 | 6 kW | 1130 mm | |

| TRHGB080A008I02 | TRHGB100A008I02 | 8 kW | 1460 mm | |

| TRHGB080A010I02 | TRHGB100A010I02 | 10 kW | 1790 mm | 120 mm |

| TRHGB080A012I02 | TRHGB100A012I02 | 12 kW | 2130 mm | |

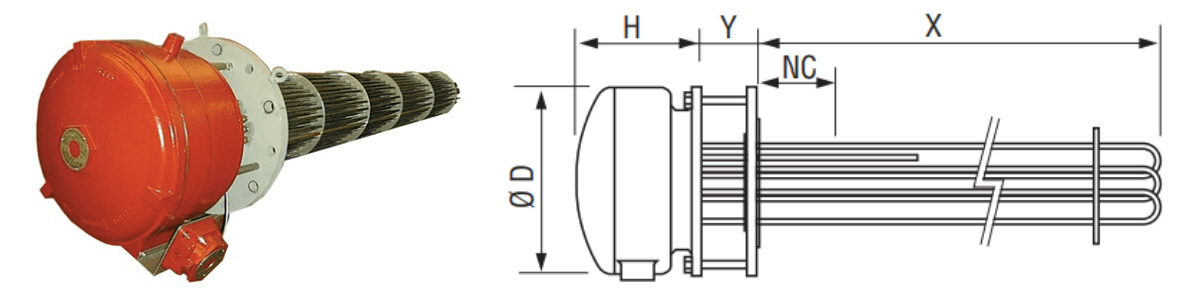

chromalox TRHGb

TRHGB are flameproof immersion heaters with sheathed elements on the flange, used to heat oil within hazardous areas.

- ATEX Certification: ATEX II 2 G – Ex d II C

- Temperature Class: T1 to T6

- Stood off stainless steel or mild steel enclosure, Ø 8″ /12″ / 14″ / 16″ / 18″ / 20″ / 26″ / 28″ / or 30″

- Flanges from DN125 up to NB30

- Mild steel or AISI 321 sheathed elements Ø 16mm

- Watts Density: 1.2 / 2 / or 4 W per sq.cm

- Feasible output up to 1350 kW

chromalox TRHC/TRHCC

TRHC and TRHCC are flameproof immersion heaters with removable sheathed elements on the flange, used to heat oil within hazardous areas.

- TRHC ATEX Certification: ATEX II 2 G – Ex d II B

- TRHCC ATEX Certification: ATEX II 2 G – Ex d II C

- Temperature Class: T1 to T6

- Version with Ø 16 mm removable sheathed elements set in pocket Ø 20 mm

- Designed with sheathed heating elements to allow their removal without draining tanks or vessels

- Feasible output up to 1350 kW (TRHCC) or 950 kW (TRHC)

- Maximum Watts Density : 4 W/cm²

chromalox TDG / TDG-S / TDG-SC

TDG, TDG-S and TDG-SC are flameproof immersion heaters with ceramic core elements, used to heat oil within hazardous areas.

- TDG/TDG-SC ATEX Certification: ATEX II 2 G – Ex d II C

- TDG/TDG-S ATEX Certification: ATEX II 2 G – Ex d II B

- Temperature Class: T1 to T6

- Version with pockets Ø 42.2 mm and removable ceramic core elements Ø 32 mm

- Feasible output up to 40 kW

- Maximum Watts Density : 4 W/cm²

chromoalox FPF

The Chromalox FPF range are ATEX immersion heaters with ANSI flanges, used to heat medium viscosity oil within hazardous areas. These heaters feature both increased safety and flameproof types of explosion protection.

- ATEX Certification: ATEX II 2 G – Ex de II C

- Temperature Class: T1 to T6

- For ambient temperature -50°C +40°C (+60°C with a longer stand off)

- Stood-off painted terminal enclosure in cast iron

- Built in pocket for optional sensor, thermostat, or cutout

- 150Ib ANSI Carbon steel flange 2½” or 3”

- Ø 11mm Incoloy 800 sheathed elements

- Watts density: 1.9 W/cm²

- Voltage: 400V / 3ph

Immersion Heater Specification

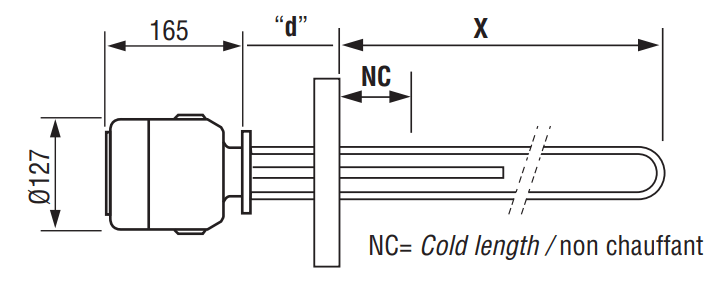

Chromalox FPF | Dimensions

Immersion Heater Product Guide

➡ Add your required temperature class (T1, T2, T3, T4, T5, or T6) at the end of the order code.

| Temperature Class | T6 | T5 | T4 | T3 | T2 | T1 |

| ‘d’ | 90 mm | 90 mm | 90 mm | 125 mm | 190 mm | 240 mm |

| Flange Size | Output | Length ‘X’ | |

| NB 2.5″ | NB 3″ | ||

| FPF 00203/12 | FPFA 00203/12 | 2000 W | 700 mm |

| FPF 00303/12 | FPFA 00303/12 | 3000 W | 965 mm |

| FPF 00403/12 | FPFA 00403/12 | 4500 W | 1375 mm |

| FPF 01603/12 | FPFA 01603/12 | 6000 W | 1780 mm |

| FPF 00903/12 | FPFA 00903/12 | 9000 W | 2585 mm |

Chromalox FPF range of hazardous area immersion heaters are also available with 5”, 6”, 8”, 10” or 12” 150 Ib ANSI carbon steel flange.

On request:

• Standard design on 14” and 16” flanges (output up to 297 kW)

• 300 to 2500 Ib ANSI flanges

• Stainless steel terminal enclosure

Option:

• Safety thermostat with automatic or manual rest

• Pt 100 safety sensor

• Thermocouple for skin temperature safety

Also available with the following watts density:

- 1.2 W/sq.cm for heavy viscosity oils (range from 4,5 up to 120 kW)

- 2.3 W/sq.cm for medium viscosity oils (range from 6 up to 180 kW)

- 3.9 W/sq.cm for light viscosity oils, ethylene glycol, (range from 12 up to 360 kW)

Chromalox FPF | Dimensions

Immersion Heater Product Guide

➡ Add your required temperature class (T1, T2, T3, T4, T5, or T6) at the end of the order code.

| Output | Length ‘X’ |

Flange Size | |||

| 5″ | 6″ | 8″ | 10″ | ||

| 4.5 kW | 720 mm | FPFA00406/12 | FPF00406/12 | – | – |

| 6 kW | 915 mm | FPFA00406/12 | FPF00606/12 | – | – |

| 9 kW | 1325 mm | FPFA00906/12 | FPF00906/12 | – | – |

| 12 kW | 640 mm | – | – | FPF01218/12 | – |

| 1730 mm | FPFA01206/12 | FPF01206/12 | – | – | |

| 15 kW | 915 mm | – | FPF01515/12 | – | – |

| 15.7 kW | 710 mm | – | – | FPF01521/12 | – |

| 18 kW | 905 mm | – | – | FPF01818/12 | – |

| 2535 mm | FPFA01806/12 | FPF01806/12 | – | – | |

| 21 kW | 505 mm | – | – | – | FPF02142/12 |

| 905 mm | – | – | FPF02121/12 | – | |

| 24 kW | 640 mm | – | – | – | FPF02436/12 |

| 905 mm | – | – | FPF02424/12 | – | |

| 1730 mm | – | FPF02412/12 | – | – | |

| 27 kW | 710 mm | – | – | – | FPF02736/12 |

| 1315 mm | – | – | FPF02718/12 | ||

| 2535 mm | FPFA02709/12 | FPF02709/12 | – | ||

| 30 kW | 905 mm | – | – | – | FPF03030/12 |

| 1730 mm | – | FPF03015/12 | – | – | |

| 31.5 kW | 1315 mm | – | – | FPF03121/12 | – |

| 36 kW | 1720 mm | – | – | – | FPF03636/12 |

| 2535 mm | – | FPF03612/12 | FPF03618/12 | – | |

| 42 kW | 1720 mm | – | – | FPF04221/12 | – |

| Output | Length ‘X’ |

6″ | 8″ | 10″ | 12″ |

| 45 kW | 890 mm | – | – | – | FPF04545/12 |

| 1315 mm | – | – | FPF04530/12 | – | |

| 2535 mm | FPF04515/12 | – | – | – | |

| 48 kW | 1720 mm | – | FPF04824/12 | – | – |

| 54 kW | 890 mm | – | – | – | FPF05454/12 |

| 1315 mm | – | – | FPF05436/12 | – | |

| 2525 mm | – | FPF05418/12 | – | – | |

| 60 kW | 1720 mm | – | – | FPF06030/12 | – |

| 63 kW | 1315 mm | – | – | FPF06342/12 | – |

| 2525 mm | – | FPF06321/12 | – | – | |

| 67.5 kW | 1300 mm | – | – | – | FPF06745/12 |

| 72 kW | 1300 mm | – | – | – | FPF07248/12 |

| 1720 mm | – | – | FPF07236/12 | – | |

| 2525 mm | – | FPF07424/12 | – | – | |

| 81 kW | 1300 mm | – | – | – | FPF08154/12 |

| 2525 mm | – | FPF08127/12 | – | – | |

| 84 kW | 1720 mm | – | – | FPF08442/12 | – |

| 90 kW | 1705 mm | – | – | – | FPF09045/12 |

| 99 kW | 2525 mm | – | – | FPF09933/12 | – |

| 102 kW | 1705 mm | – | – | – | FPF10251/12 |

| 108 kW | 1705 mm | – | – | – | FPF10854/12 |

| 2525 mm | – | – | FPF10836/12 | – | |

| 114 kW | 1705 mm | – | – | – | FPF11457/12 |

| 117 kW | 2525 mm | – | – | FPF11739/12 | – |

| 120 kW | 1705 mm | – | – | – | FPF12060/12 |

| 126 kW | 2525 mm | – | – | FPF12642/12 | – |

| 135 kW | 2510 mm | – | – | – | FPF13545/12 |

| 144 kW | – | – | – | FPF14448/12 | |

| 153 kW | – | – | – | FPF15351/12 | |

| 162 kW | – | – | – | FPF16254/12 | |

chromalox FPFr

Chromalox FPFR are ATEX immersion heaters with removable elements, used to heat medium viscosity oil, where heating elements need to be replaced with a minimum of down time and no need to drain down the system, within hazardous areas.

These heaters feature both increased safety and flameproof types of explosion protection.

- ATEX Certification: ATEX II 2 G – Ex de II C

- Temperature Class: T1 to T6

- For ambient temperature -50°C +40°C (+60°C with a longer stand off)

- Stood-off painted terminal enclosure in cast iron

- 150Ib ANSI Carbon steel flange 2½”

- Stainless steel sheathed heating elements in mild steel pocket

- Built in pocket for optional sensor, thermostat, or cutout

- Watts density: 1.9 W/cm²

Immersion Heater Specification

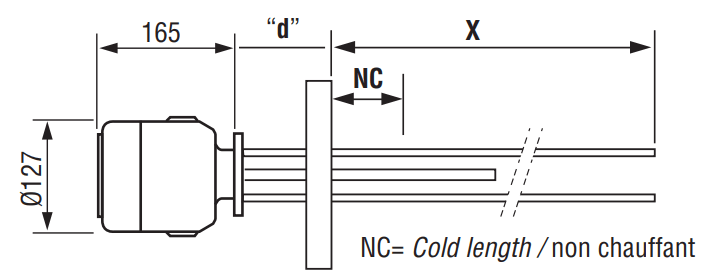

Chromalox FPFR | Dimensions

| Temperature Class | T6 | T5 | T4 | T3 | T2 | T1 |

| ‘d’ | 90 mm | 90 mm | 90 mm | 125 mm | 190 mm | 240 mm |

Immersion Heater Product Guide

➡ Add your required temperature class (T1, T2, T3, T4, T5, or T6) at the end of the order code.

| Chromalox Order Code | Output | Length ‘X’ |

| FPFR 00303/12 | 3000 W | 970 mm |

| FPFR 00603/12 | 6000 W | 1830 mm |

| FPFR 00903/12 | 9000 W | 2670 mm |

Like the FPF range, Chromalox FPFR range of hazardous area immersion heaters are also available with 5”, 6”, 8”, 10” or 12” 150 Ib ANSI carbon steel flange.

On request:

• Standard design on 14” flanges (output up to 172 kW)

• 300 to 2500 Ib ANSI flanges

• Stainless steel enclosure

Option:

• Safety thermostat with automatic or manual rest

• Pt 100 safety sensor

• Thermocouple for skin temperature safety

Chromalox FPFR | Dimensions

Immersion Heater Product Guide

➡ Add your required temperature class (T1, T2, T3, T4, T5, or T6) at the end of the order code.

| Output | Length ‘X’ | Flange Size | Weight | |||

| 6″ | 8″ | 10″ | 12″ | |||

| 6 kW | 970 mm | FPFR00606/12 | – | – | – | 21 kg |

| 9 kW | FPFR00901/12 | – | – | – | 25 kg | |

| 12 kW | FPFR01212/12 | – | – | – | 29 kg | |

| 15 kW | – | FPFR01515/12 | – | – | 40 kg | |

| 18 kW | 970 mm | – | – | FPFR01810/12 | – | 57 kg |

| 1830 mm | FPFR01801/12 | – | – | – | 37 kg | |

| 2670 mm | FPFR01806/12 | – | – | – | 41 kg | |

| 21 kW | 970 mm | – | – | FPFR02121/12 | – | 60 kg |

| 24 kW | 970 mm | – | – | FPFR02424/12 | – | 64 kg |

| 1830 mm | – | FPFR02412/12 | – | – | 53 kg | |

| 27 kW | 970 mm | – | – | FPFR02727/12 | – | 68 kg |

| 2670 mm | FPFR02709/12 | – | – | – | 40 kg | |

| 30 kW | 1830 mm | – | FPFR03015/12 | – | – | 60 kg |

| 33 kW | 970 mm | – | – | – | FPFR03333/12 | 93 kg |

| 36 kW | 970 mm | – | – | – | FPFR03636/12 | 96 kg |

| 1830 mm | – | – | FPFR03618/12 | – | 81 kg | |

| 2670 mm | – | FPFR03612/12 | – | – | 69 kg | |

| 39 kW | 970 mm | – | – | – | FPFR03939/12 | 100 kg |

| 42 kW | 970 mm | – | – | – | FPFR04242/12 | 104 kg |

| 1830 mm | – | – | FPFR04221/12 | – | 88 kg | |

| 45 kW | 2670 mm | – | FPFR04515/12 | – | – | 70 kg |

| 48 kW | 1830 mm | – | – | FPFR04824/12 | – | 96 kg |

| 54 kW | 1830 mm | – | – | FPFR05427/12 | – | 104 kg |

| 2670 mm | – | – | FPFR05418/12 | – | 117 kg | |

| 60 kW | 1830 mm | – | – | FPFR06030/12 | – | 111 kg |

| 63 kW | 2670 mm | – | – | FPFR06321/12 | – | 116 kg |

| 66 kW | 1830 mm | – | – | – | FPFR06633/12 | 137 kg |

| 72 kW | 1830 mm | – | – | – | FPFR07236/12 | 144 kg |

| 2670 mm | – | – | FPFR07224/12 | – | 128 kg | |

| 78 kW | 1830 mm | – | – | – | FPFR07839/12 | 152 kg |

| 81 kW | 2670 mm | – | – | FPFR08127/12 | – | 140 kg |

| 84 kW | 1830 mm | – | – | – | FPFR08442/12 | 160 kg |

| 90 kW | 2670 mm | – | – | FPFR09030/12 | – | 151 kg |

| 99 kW | – | – | – | FPFR09933/12 | 180 kg | |

| 108 kW | – | – | – | FPFR10836/12 | 192 kg | |

| 117 kW | – | – | – | FPFR11739/12 | 204 kg | |

| 126 kW | – | – | – | FPFR12642/12 | 216 kg | |

chromalox exf

Chromalox EXF range are increased safety immersion heaters which are used to heat medium viscosity oil within hazardous areas.

- ATEX Certification: ATEX II 2 G – Ex e

- Temperature Class: T1 to T6

- For Ambient Temperatures: -50°C +40°C (+55°C on request)

- Ingress Protection Rating: IP66

- Stood-off stainless steel terminal enclosure

- 150 Ib ANSI carbon steel flange, 4”, 6”, 8”, 10”, or 12”

- Ø11 Incoloy 800 sheathed elements

- Watts density 1.9 W /sq.cm

- Voltage 400V / 3Ph

Note: Also standardized ranges with Watts density:

– 1.2 W/sq.cm for heavy oils (range 3 to 72 kW)

– 2.3 W/sq.cm for medium oils (range 1.5 to 108 kW)

– 3.9 W/sq.cm for light oils, ethylene glycol (range 3 to 216 kW)

On request:

• Standard design on 14” and 16” flanges: output up to 180 kW (1.9 and 2.3 W / sq.cm), or 360 kW (3.9 W / sq.cm)

➡ Add your required temperature class (T1, T2, T3, T4, T5, or T6) at the end of the order code.

| Output | Length ‘X’ |

Flange Size | |||

| 4″ | 6″ | 8″ | 10″ | ||

| 3 kW | 980 mm | EXF00303/12 | – | – | – |

| 4.5 kW | 785 mm | – | EXF00406/12 | – | – |

| 1390 mm | EXF00403/12 | – | – | – | |

| 6 kW | 980 mm | – | EXF00606/12 | – | – |

| 1795 mm | EXF00603/12 | – | – | – | |

| 9 kW | 1390 mm | – | EXF00906/12 | – | – |

| 2600 mm | EXF00903/12 | – | – | – | |

| 12 kW | 975 mm | – | – | EXF01212/12 | – |

| 1795 mm | – | EXF01206/12 | – | – | |

| 13.5 kW | 1390 mm | – | EXF01306/12 | – | – |

| 15 kW | 975 mm | – | – | EXF01515/12 | – |

| 18 kW | 1385 mm | – | – | EXF01812/12 | – |

| 2600 mm | – | EXF01806/12 | – | – | |

| 21 kW | 975 mm | – | – | EXF02215/12 | EXF02121/12 |

| 22.5 kW | 1385 mm | – | – | – | – |

| 24 kW | 975 mm | – | – | EXF02412/12 | EXF02424/12 |

| 1790 mm | – | – | – | – | |

| 27 kW | 1385 mm | – | – | – | EXF02718/12 |

| 2600 mm | – | EXF02709/12 | – | – | |

| 30 kW | 1790 mm | – | – | EXF03015/12 | – |

| 31.5 kW | 1385 mm | – | – | – | EXF03121/12 |

| Output | Length ‘X’ |

6″ | 8″ | 10″ | 12″ |

| 36 kW | 970 mm | – | – | – | EXF03636/12 |

| 1790 mm | – | – | EXF03618/12 | – | |

| 2595 mm | – | EXF03612/12 | – | – | |

| 42 kW | 1790 mm | – | – | EXF04221/12 | – |

| 45 kW | 1380 mm | – | – | – | EXF04530/12 |

| 2595 mm | – | EXF04515/12 | – | – | |

| 48 kW | 1790 mm | – | – | EXF04824/12 | – |

| 54 kW | 1315 mm | – | – | – | EXF05436/12 |

| 2525 mm | – | – | EXF05418/12 | – | |

| 60 kW | 1785 mm | – | – | – | EXF06030/12 |

| 63 kW | 2595 mm | – | – | EXF06321/12 | – |

| 66 kW | 1785 mm | – | – | – | EXF06633/12 |

| 72 kW | 1785 mm | – | – | – | EXF07236/12 |

| 2595 mm | – | – | EXF02724/12 | – | |

| 81 kW | 1705 mm | – | – | EXF08127/12 | – |

| 90 kW | 1705 mm | – | – | – | EXF09030/12 |

| 99 kW | 2525 mm | – | – | – | EXF09933/12 |

| 108 kW | 1705 mm | – | – | – | EXF10836/12 |

Contact Thorne & Derrick for excellent customer service, competitive quotations and delivery from stock for Chromalox heaters

Explosion Proof Exd Flameproof Heaters | Exd Radiators | Exe Increased Safety Heaters | Explosion Proof Convection Heaters | Exd Flameproof Heaters | Distributed by Thorne & Derrick | Experts in Equipment for Explosive Atmospheres

Experts in Equipment for Explosive Atmospheres

Learn more about our ATEX & IECEx Product Innovations and how we deliver significant improvements to clients plant, people and operational safety in the explosive atmosphere industries – we service UK and international projects with a comprehensive range of certified Electrical, HVAC and Process Instrumentation equipment for the hazardous area industries.

Hazardous Area ELECTRICAL, MECHANICAL & PROCESS INSTRUMENTATION Specialists

Thorne & Derrick International distribute Electrical, Mechanical, Process & Instrumentation Equipment to the global hazardous area industries and are approved vendors to most leading oil, gas and petrochemical companies and their EPC’s.

T&D supply ATEX & IECEx Certified equipment for the detection, metering, flow measurement and heat tracing of potentially explosive gases in hazardous areas Zone 1 and Zone 2 (Explosive Gas) and Zone 21 and Zone 22 (Explosive Dust).

Hazardous Area Equipment | Gas Detection | Metering | Lighting | Process Instrumentation | Plugs & Connectors | Trace Heating

Chromalox Product Range | Hazardous Area Heating | Immersion Heaters | Trace Heating Cables