SICK GM700 Gas Analyser – Laser Gas Analyser (Ammonia, Hydrogen Fluoride, Hydrogen Chloride)

In-Situ Gas Analysers

SICK GM700

The SICK GM700 in-situ laser gas analyser offers high reliability and precision as well as minimal response times. By using specific light absorption and Tunable Diode Laser Spectroscopy, or TDLS, the SICK GM700 is able to measure several gas components, such as NH3, HF, HCl or H2O.

In-situ gas analysers are ideal for quickly determining gas concentrations in process control and emission monitoring .

Fields of applications for the SICK GM700 include ammonia slip measurement in DeNox plants, emission monitoring of hydrogen fluoride in aluminium smelters, ammonia measurement in exhaust gas of combustion engines, ammonia measurement in composting or waste incineration plants, HCI measurement in combustion plants and HF measurement in the ceramics industry.

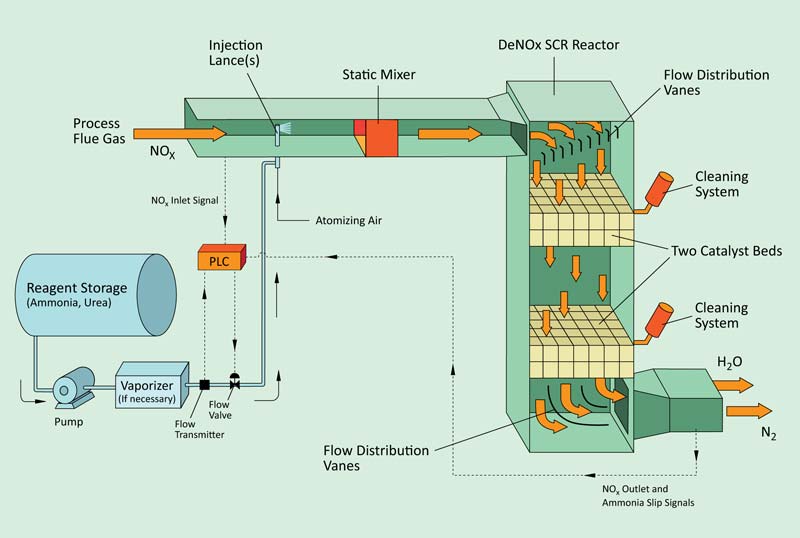

Image : McGill AirClean

DeNOx

Selective Catalytic Reduction (SCR) is the process of NOx gas reduction, or DeNOx, that occurs when a NOx source is mixed with ammonia and allowed to react at the surface of the proper catalyst – the liquid ammonia injected upstream immediately turns into gas, mixes with the NOx gas and the mixture then reacts at the catalyst.

SICK GM700 Gas Analyser – Features

- High selectivity due to high spectral resolution

- Short response times

- No calibration required

- No moving parts: minimal wear and tear

- No gas sampling or conditioning required

- Overpressure encapsulated design for ATEX Zone 2

➡ Did you know? T&D also distribute SICK level sensors, flow sensors, pressure sensors and temperature sensors.

Hazardous Area Gas Analysers

SICK GM700

Technical SPECIFICATION

GM700 Gas Analyser System – Standard Version

| Description | In-situ gas analyser for emission monitoring and process measurement |

| Measured Values | NH3, HF, HCl, H2O |

| Performance-Tested Measurands | HF |

| Measurement Principles | Diode laser spectroscopy (TDLS) |

| Ambient Temperature | –20 °C … +55 °C Depends on parameterization; temperature change max. ±10 °C/h |

| Storage Temperature | –40 °C … +55 °C |

| Ambient Humidity | ≤ 95 % Relative humidity; non-condensing |

| Conformities (Only for HF) | Approved for plants requiring approval 2001/80/EC (13. BImSchV) 2000/76/EC (17. BImSchV) 27. BImSchV TA-Luft (Prevention of Air Pollution) EN 15267 EN 14181 MCERTS GOST |

| Electrical Safety | CE |

| Test Functions | Automatic check cycle for zero and span point (only for NH3 and HCl) |

| Mounting | Mounting flange, DN125, PN6 |

| Mounting flange, ANSI, 5″ | |

| Options | SCU control unit (for non-hazardous areas only) |

| Accuracy | |

| Zero Point | ± 2 %: relative to measuring range end value |

| Reference Point | ± 2 %: within the maintenance interval (6 months), relative to measuring range full scale |

| Measuring Ranges (Measuring ranges refer to 1 m measuring path & depend on application and device version) |

|

| NH3 (up to 20% H2O by volume) | 0 … 25 ppm / 0 … 4,000 ppm |

| NH3 (up to 40% H2O by volume) | 0 … 25 ppm / 0 … 100 ppm |

| HCl | 0 … 10 ppm / 0 … 3,000 ppm |

| HF | 0 … 5 ppm / 0 … 2,000 ppm |

| Dual Measuring Ranges | |

| HCl / H2O | 0 … 10 ppm / 0 … 3,000 ppm (HCl) 0 … 50 Vol.-% / 0 … 100 Vol.-% (H2O) |

| NH3 / H2O | 0 … 25 ppm / 0 … 4,000 ppm (NH3) 0 … 20 Vol.-% / 0 … 20 Vol.-% (H2O) |

| NH3 / H2O | 0 … 25 ppm / 0 … 100 ppm (NH3) 0 … 40 Vol.-% / 0 … 40 Vol.-% (H2O) |

| Certified Measuring Ranges (Suitability-tested in the cross-duct type) |

|

| HF | 0 … 5 mg/m³ / 0 … 25 mg/m³ |

| Response Time (t90) | |

| Standard | 1 s … 360 s Adjustable, pre-set to 4 s |

| HF Measurement | 1 s … 180 s Adjustable, pre-set to 4 s, suitability-tested according to EN 15267 |

Gas Measurement Using SICK GM700 Laser Gas Analyser Applications

GM700 Gas Analyser System – Ex Version

| Description | In-situ gas analyser for emission monitoring and process measurement |

| Measured Values | NH3, H2O |

| Measurement Principles | Diode laser spectroscopy (TDLS) |

| Process Temperature | –20 °C … +200 °C |

| Ambient Temperature | –20 °C … +50 °C Depends on parameterization; temperature change max. ±10 °C/h |

| Storage Temperature | –20 °C … +50 °C |

| Ambient Humidity | ≤ 95 % Relative humidity; non-condensing |

| Response Time (t90) | 1 s … 360 s Adjustable, pre-set to 4 s |

| Hazardous Area Approvals | ATEX II 3/-G Ex pzc op is [ia] IIC T4 Gc/- |

| Electrical Safety | CE |

| Test Functions | Automated control cycle for zero and reference point (only for NH3) |

| Mounting | Mounting flange, DN125, PN6 |

| Mounting flange, ANSI, 5″ | |

| Accuracy | |

| Zero Point | ± 2 %: relative to measuring range end value |

| Reference Point | ± 2 %: within the maintenance interval (6 months), relative to measuring range full scale |

| Measuring Ranges (Measuring ranges refer to 1 m measuring path & depend on application and device version) |

|

| NH3 | 0 … 25 ppm / 0 … 4,000 ppm |

| Dual Measuring Ranges (Measuring ranges refer to 1 m measuring path & depend on application and device version) |

|

| NH3 / H2O | 0 … 25 ppm / 0 … 4,000 ppm (NH3) 0 … 20 Vol.-% / 0 … 20 Vol.-% (H2O) |

SICK GM700 Sender/Receiver Unit (Ex Version)

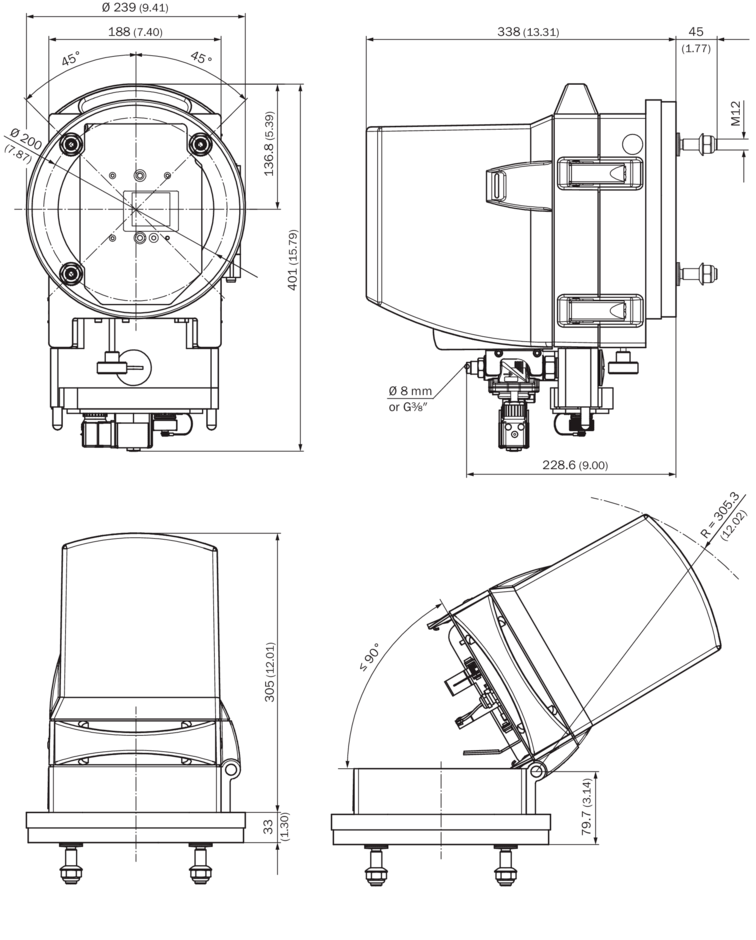

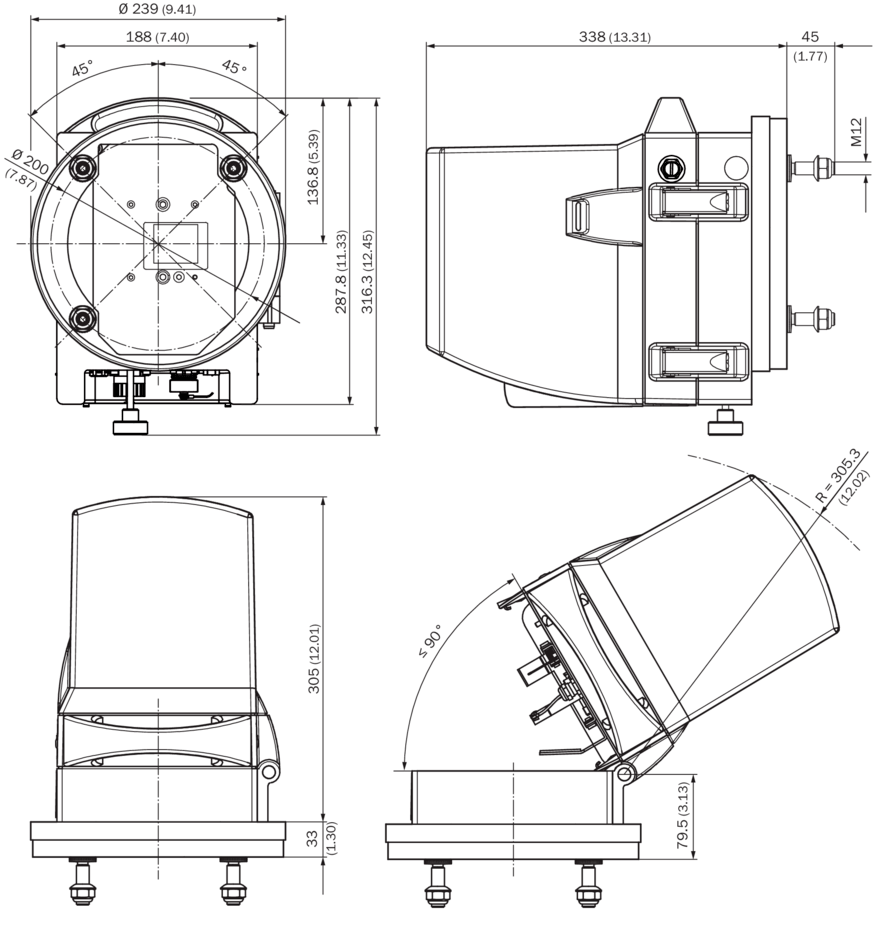

Sender/Receiver Unit – Standard & Ex Versions

| Description | Analyser unit of the measuring system |

| Electrical Safety | CE |

| Enclosure Rating | IP66 / NEMA 4x |

| Dimensions (W x H x D) | Standard Gas Analyser – 239 mm x 316 mm x 338 mm Ex-Rated Gas Analyser – 239 mm x 401 mm x 338 mm |

| Weight | Standard Gas Analyser – 13kg Ex-Rated Gas Analyser – 14kg |

| Power Supply | |

| Voltage | 24 V DC Supply via connection unit |

| Power Consumption | 36 W |

SICK GM700 – Sender/Receiver Unit (Standard Version)

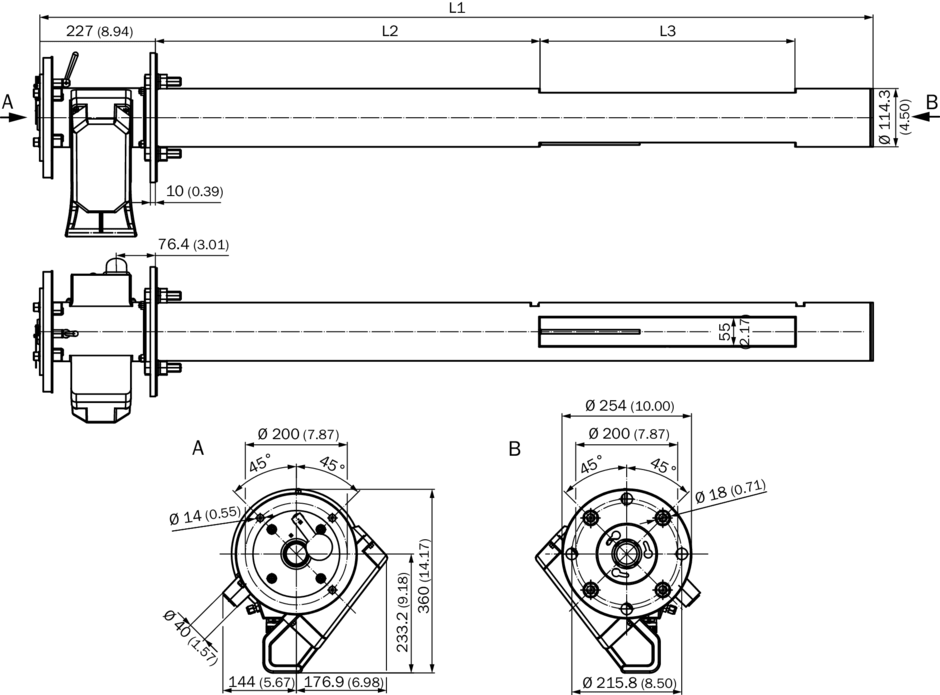

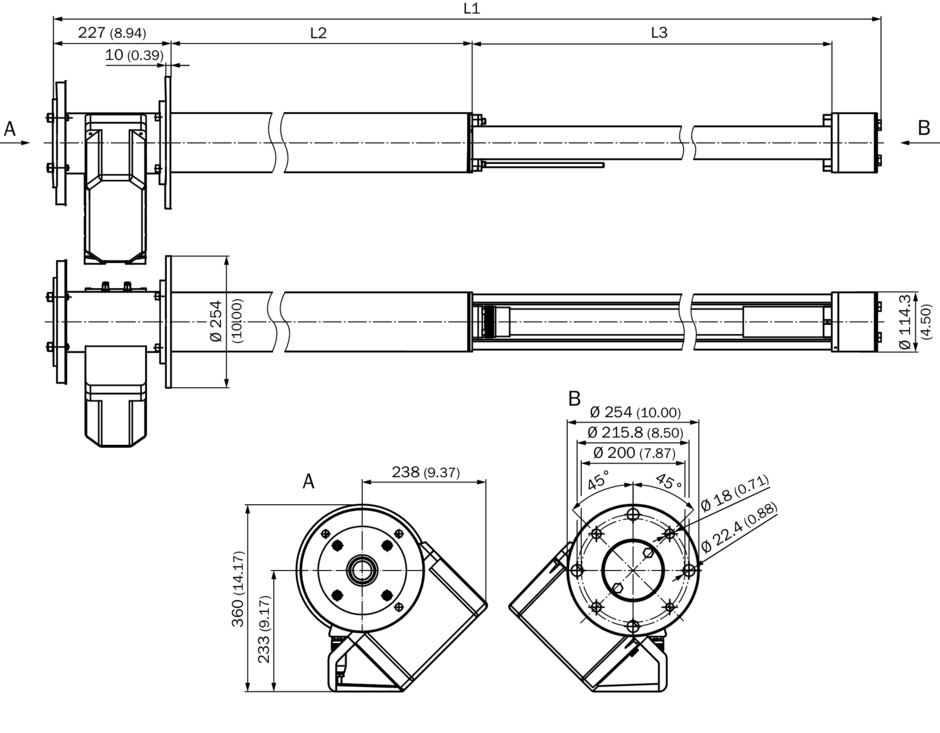

Open Measuring Probe (GMP)

| Description | Measuring probe in open design with integrated purge air control system |

| Measuring Distance | see Data Sheet |

| Accuracy | |

| Pressure Sensor | 1% |

| Temperature Sensor | 1% |

| Process Temperature | Standard Version – ≤ +250 °C (From 200 °C with heated purge air) Ex Version – ≤ +200 °C |

| Process Pressure | –60 hPa … 30 hPa Depending on purge air supply |

| Dust Load | ≤ 3 g/m³ Based on a 1 m measuring distance, depending on application |

| Enclosure Rating | IP66 |

| Electrical Safety | CE |

| Dimensions (W x H x D) | see Data Sheet |

| Weight | |

| Material in Contact with Media | Stainless steel 1.4571, stainless steel 1.4539 |

| Voltage | Supply via sender/receiver unit |

| Auxiliary Gas Connections – Purge Air | Hose nozzle 40 mm |

| Integrated Components | Pressure sensor (Not Ex version) PT1000 temperature sensor (Not Ex version) Flow monitor for purge air monitoring |

SICK GM700 IN-Situ Gas Analyser | Open Measuring Probe (GMP)

Gas-Testable Measuring Probe (GPP)

| Description | Measuring probe with gas permeable filter element for adjustment with test gas |

| Measuring Distance | see Data Sheet |

| Accuracy | Pressure Sensor: 1% |

| Temperature Sensor: 1% | |

| Process Temperature | HCl: +130 °C … +430 °C NH3: +300 °C … +430 °C |

| Process Pressure | –120 hPa … 200 hPa |

| Dust Load | ≤ 30 g/m³ |

| Electrical Safety | CE |

| Enclosure Rating | IP65 |

| Dimensions (W x H x D) | see Data Sheet |

| Weight | |

| Material in Contact with Media | Stainless steel 1.4571, stainless steel 1.4539, ceramics, PTFE |

| Integrated Components | Pressure sensor PT1000 temperature sensor Heating of optical surfaces |

| Power Supply | |

| Voltage | 150 V AC / 230 V AC |

| Frequency | 50 Hz / 60 Hz |

| Power Consumption | ≤ 150 W |

| Auxiliary Gas Connections | |

| Test Gas | Clamp connection 1/4″ |

SICK GM700 IN-Situ Gas Analyser | Gas-Testable Measuring Probe (GPP)

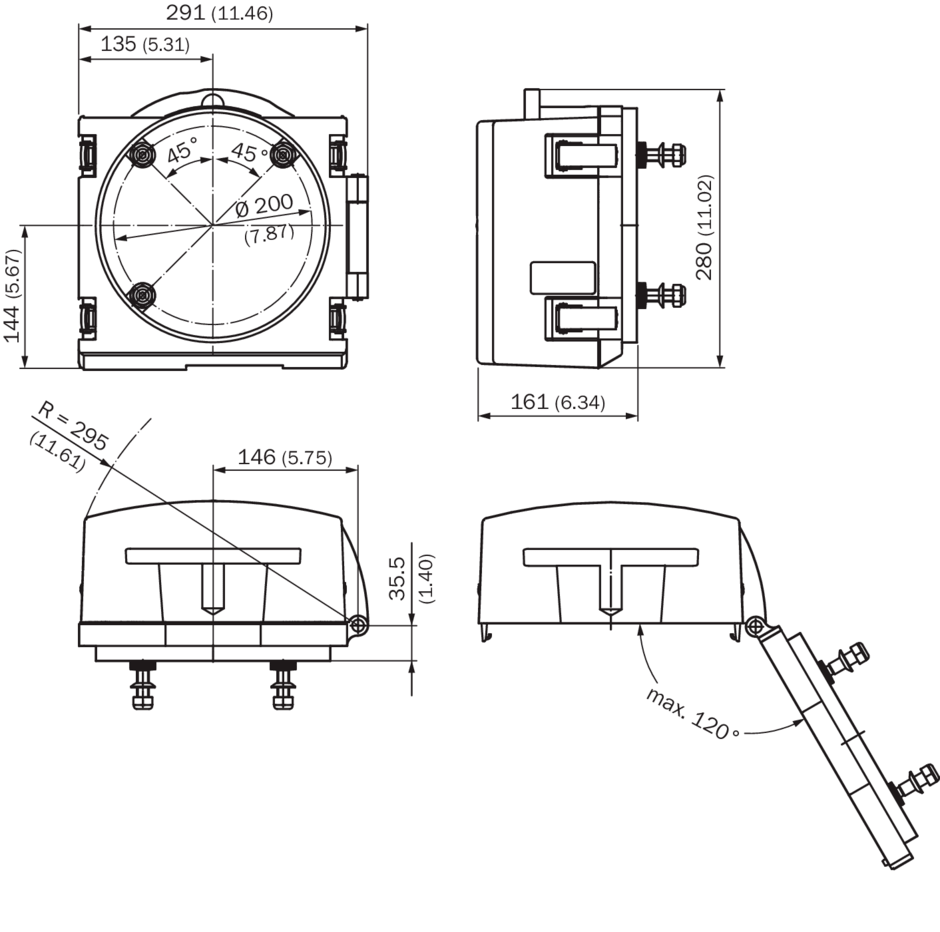

Reflector Unit (Cross-Duct Version)

| Description | Reflector unit with hollow triple reflector |

| Electrical Safety | CE |

| Enclosure Rating | IP65 |

| Dimensions (W x H x D) | 291 mm x 280 mm x 161 mm |

| Weight | 8.5 kg |

| Measuring Distance | 0.25 m … 6 m Flange – flange distance minus 2 x flange length |

| Process Temperature | ≤ +250 °C From 200 °C with heated purge air |

| Process Pressure | –60 hPa … 30 hPa Depending on purge air supply |

| Dust Load | ≤ 3 g/m³ Based on a 1 m measuring distance, depending on application |

SICK GM700 In-Situ Gas Analyser – Reflector Unit

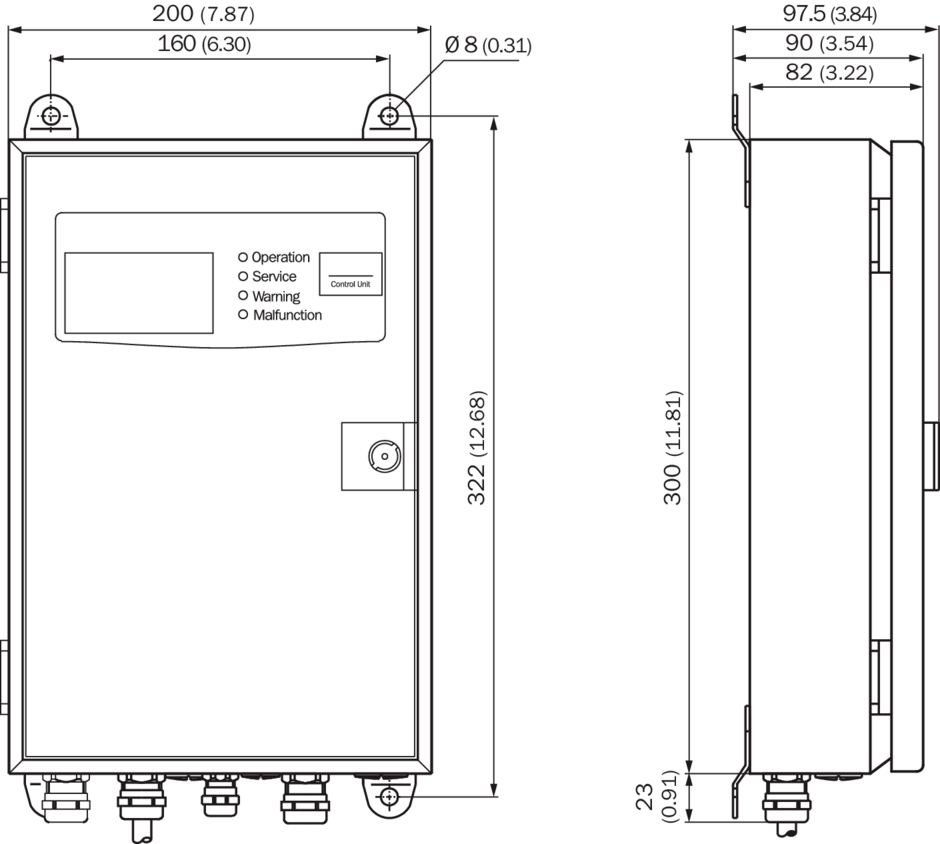

AWE Control Unit – Sheet Steel Housing

| Description | The control unit serves as the human machine interface and is responsible for data processing and output as well as control and monitoring functions. |

| Electrical Safety | CE |

| Enclosure Rating | IP65 |

| Indication | LC display Status LEDs: “Operation”, “Service”, “Warning” and “Malfunction” Arrow Keys |

| Analog Outputs | 3 outputs: 0/4 … 20 mA, 500 Ω – Electrically isolated |

| Analog Inputs | 2 inputs: 0 … 20 mA, 100 Ω – For gas temperature and gas pressure |

| Digital Outputs | 3 relay contacts: 48 V AC, 1 A, 60 W / 48 V DC, 1 A, 30 W Pre-set for failure, maintenance and functional control |

| Digital Inputs | 3 inputs: 24 V |

| Communication Interface (Only for HF) | Serial CAN bus PROFIBUS DP |

| Type of fieldbus integration | RS-232 |

| Function | Proprietary service interface & Internal system bus |

| Number | 1 |

| Operation | Menu driven operation via LC-display & membrane keyboard |

| Model | Steel sheet enclosure |

| Dimensions (W x H x D) | 200 mm x 346 mm x 97.5 mm |

| Weight | ≤4.7 kg |

| Voltage | 115 V / 230 V |

| Frequency | 50 Hz / 60 Hz |

| Power Consumption | ≤ 50 W |

| Input | Arrow keys Function Keys |

SICK GM700 In-Situ Gas Analyser | Control Unit (Sheet Steel Housing)

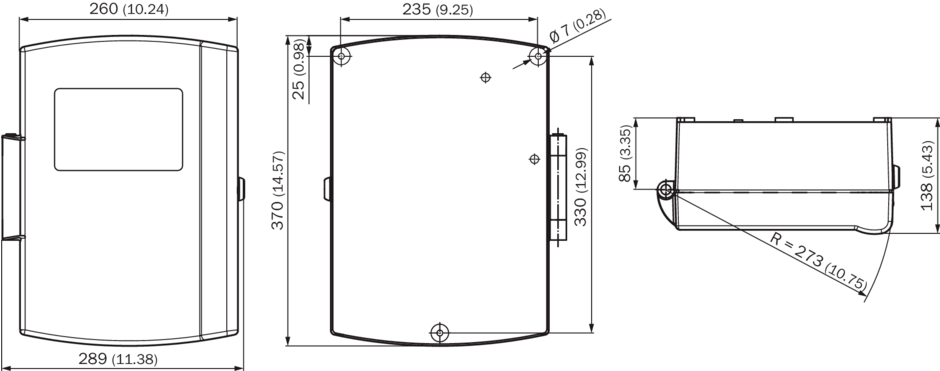

AWE Control Unit – Cast Metal Enclosure

| Description | The control unit serves as the human machine interface and is responsible for data processing and output as well as control and monitoring functions. |

| Electrical Safety | CE |

| Enclosure Rating | IP67 |

| Indication | LC display Status LEDs: “Operation”, “Service”, “Warning” and “Malfunction” Arrow Keys |

| Analog Outputs | 3 outputs: 0/4 … 20 mA, 500 Ω Electrically isolated |

| Analog Inputs | 2 inputs: 0 … 20 mA, 100 Ω For gas temperature and gas pressure |

| Digital Outputs | 3 relay contacts: 48 V AC, 1 A, 60 W / 48 V DC, 1 A, 30 W Pre-set for failure, maintenance and functional control |

| Digital Inputs | 3 inputs: 24 V |

| Communication Interface (Only for HF) | Serial CAN bus PROFIBUS DP |

| Type of fieldbus integration | RS-232 |

| Function | Proprietary service interface & Internal system bus |

| Operation | Menu driven operation via LC-display & membrane keyboard |

| Model | Cast metal enclosure |

| Dimensions (W x H x D) | 289 mm x 370 mm x 138 mm |

| Weight | 8.6 kg |

| Power Supply | |

| Voltage | 115 V / 230 V |

| Frequency | 50 Hz / 60 Hz |

| Power Consumption | ≤ 50 W |

| Input | Arrow keys Functional keys |

SICK GM700 In-Situ Gas Analyser Control Unit (Cast Metal Housing)

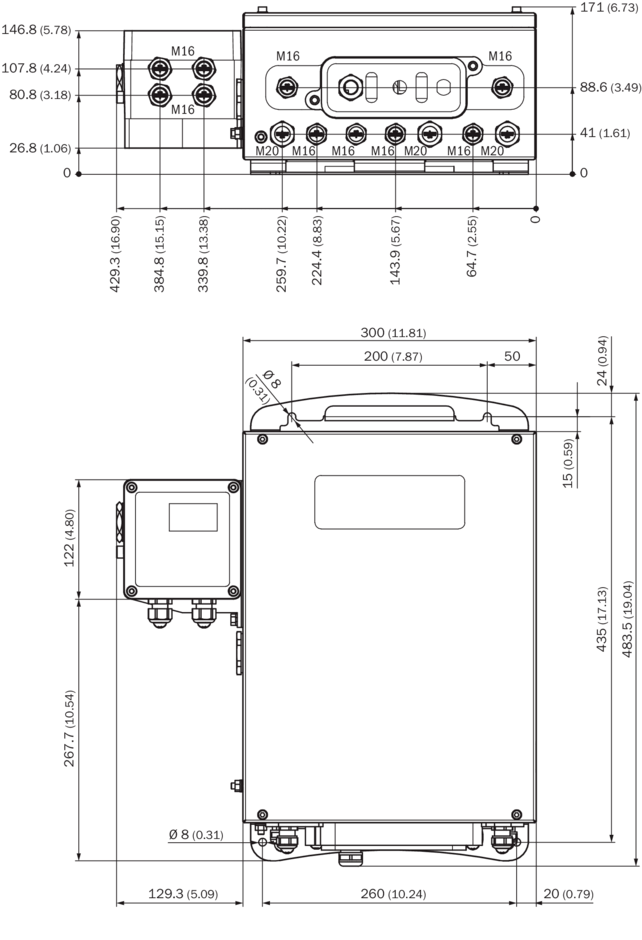

SICK GM700-EX3G control unit

| Description | The control unit serves as the human machine interface and is responsible for data processing and output as well as control and monitoring functions. |

| Electrical Safety | CE |

| Enclosure Rating | IP65 |

| Analog Outputs | 3 outputs: 0/4 … 20 mA, 500 Ω Electrically isolated |

| Analog Inputs | 2 inputs: 0 … 20 mA, 100 Ω For gas temperature and gas pressure |

| Digital Outputs | 3 relay contacts: 48 V AC, 1 A, 60 W / 48 V DC, 1 A, 30 W Pre-set for failure, maintenance and functional control |

| Digital Inputs | 3 inputs: 24 V |

| Communication Interface | Serial Type of fieldbus integration: RS-232 Function: Proprietary service interface |

| Number | 1 |

| Indication | LC Display Status LEDs: “Operation”, “Service”, “Warning” and “Malfunction” |

| Input | Arrow keys Functional keys |

| Operation | Menu-driven operation via LC-display and membrane keyboard |

| Model | Steel sheet enclosure |

| Dimensions (W x H x D) | Control unit: 300 mm x 483 mm x 138 mm Ex pz control unit FS840: 129 mm x 122 mm x 120 mm |

| Weight | ≤ 16 kg |

| Power Supply | Voltage: 230 V Frequency: 50 Hz Power Consumption: ≤ 75 W |

In-Situ Gas Analysers | SICK GM700-EX3G – Control Unit

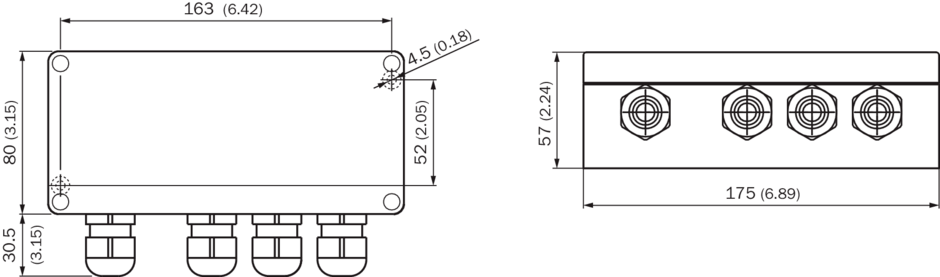

SICK GM-700 Connection Unit

| Description | For extending the internal CAN bus connection with a cable provided by the customer |

| Electrical Safety | CE |

| Enclosure Rating | IP66 |

| Dimensions (W x H x D) | 175 mm x 110.5 mm x 175 mm |

| Weight | 3 kg |

| Power Supply | Voltage: 115 V/230 V Frequency: 50 Hz/60 Hz |

| Integrated Components | On-board 24 V power supply for the sender/receiver unit |

SICK GM700 In-Situ Gas Analyser – Connection Unit

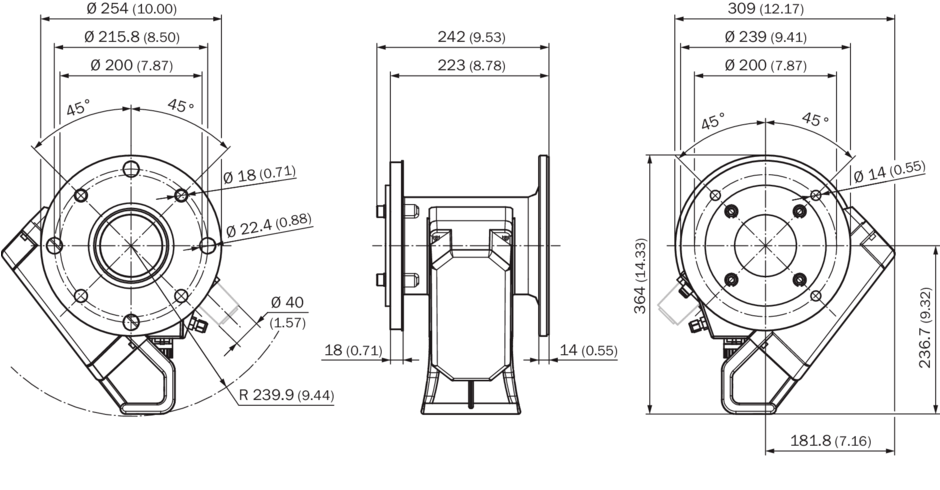

Purge Air Fixture

| Description | Flange fixture for connections for purge air hose, temperature and pressure sensor |

| Electrical Safety | CE |

| Dimensions (W x H x D) | 309 mm x 364 mm x 242 mm |

| Weight | 9.6 kg |

| Auxiliary Gas Connections: Purge Air | Hose nozzle 40 mm |

| Electrical Connections | PT1000 temperature sensor Flow monitor |

| Integrated Components | Flow monitor for purge air monitoring Pressure sensor (only for sender/receiver unit) Temperature sensor (only for sender/receiver unit) |

Sick GM700 Purge Air Fixture

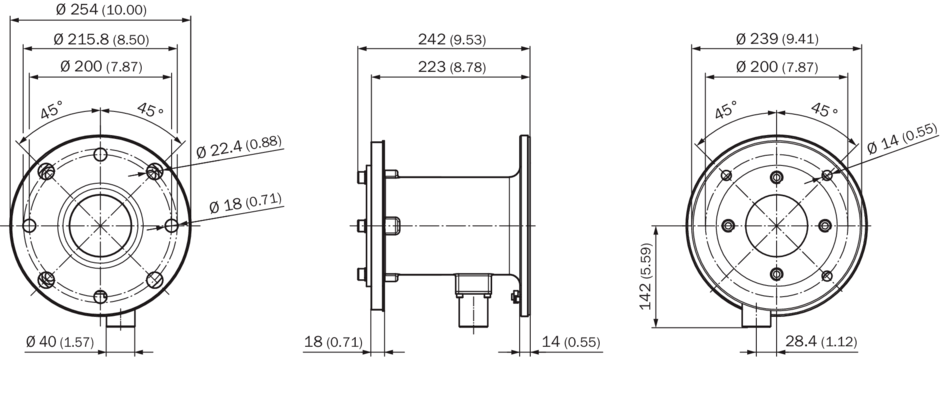

Purge air attachment – Ex version (passive)

| Description | Flange fixture for connections for purge air hose and purge air monitoring |

| Electrical Safety | CE |

| Dimensions (W x H x D) | 254 mm x 269 mm x 242 mm |

| Weight | 7 kg |

| Auxiliary Gas Connections: Purge Air | Hose nozzle 40 mm |

SICK GM700 In-Situ Gas Analysers Purge air attachment Ex Version (passive)

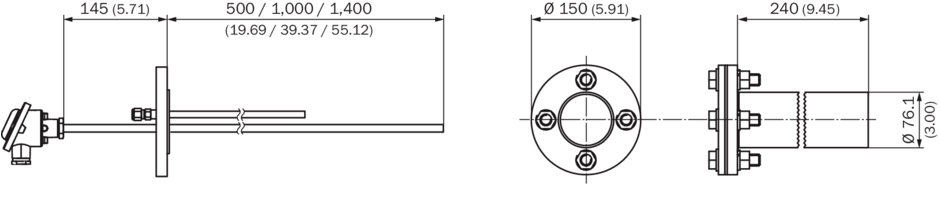

Pressure and Temperature Sensor (Cross-Duct Version)

| Description | Pressure and temperature sensor with DN40 / PN40 mounting flange |

| Accuracy | Pressure Sensor – 1% Temperature Sensor – 1% |

| Process Temperature | ≤ +500 °C |

| Electrical Safety | CE |

| Dimensions (W x H x D) | Dimensions may vary. see Data Sheet |

| Immersion Depth – PT1000 Temperature Sensor | 500mm 1000mm 1400mm |

| Material | Stainless steel 1.4571, steel ST37 |

| Scope of Delivery | Connecting cable for temperature sensor, 5m Connecting hose for pressure sensor, 5 m Flange cover, including seal and screws |

SICK GM700 In-Situ Gas Analyser Pressure and temperature sensor with DN40/PN40 Mounting Flange

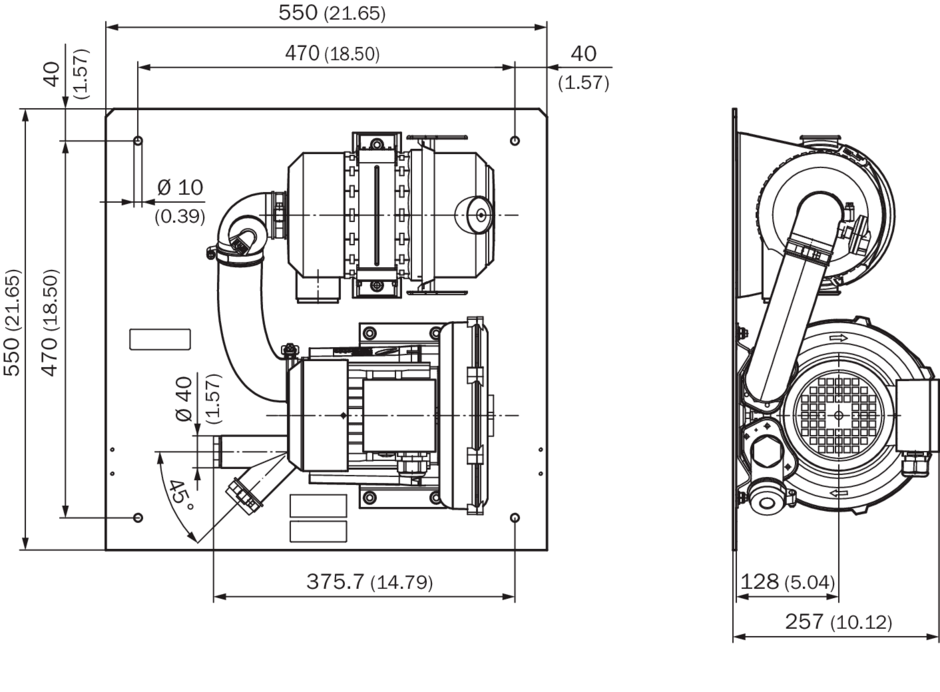

SLV4-2 Purge Air Unit, 2BH1300, 3-ph

| Description | Unit to provide dust-free air for flushing of optical surfaces |

| Gas Flow Rate | 38 m³/h … 63 m³/h At 30 hPa counter pressure, depending on low pressure inside the filter |

| Ambient Temperature | –40 °C … +55 °C |

| Electrical Safety | CE |

| Enclosure Rating | IP54 |

| Dimensions (W x H x D) | 550 mm x 550 mm x 258 mm |

| Weight | 18 kg |

| Power Supply – Three-Phase Current | Δ: 200 … 240 V, 50 Hz, 2,6 A, 400 W Y: 345 … 415 V, 50 Hz, 1,5 A, 400 W Δ: 200 … 275 V, 60 Hz, 2,6 A, 500 W Y: 380 … 480 V, 60 Hz, 1,5 A, 500 W Δ: 270 … 330 V, 50 Hz, 2,0 A, 400 W Y: 465 … 570 V, 50 Hz, 1,16 A, 400 W Δ: 290 … 360 V, 60 Hz, 2,1 A, 500 W Y: 500 … 600 V, 60 Hz, 1,26 A, 500 W Δ: 230 V, 50 Hz, 2,7 A, 370 W Δ: 115 V, 60 Hz, 3,0 A, 450 W Δ: 220 … 270 V, 50 Hz, 2,5 A, 400 W Y: 380 … 465 V, 50 Hz, 1,45 A, 400 W Δ: 240 … 290 V, 60 Hz, 2,6 A, 500 W Y: 415 … 500 V, 60 Hz, 1,55 A, 500 W |

| Auxiliary Gas Connections: Purge Air | Hose nozzle 40 mm |

| Test Functions | Pressure switch (switching point –35 hPa) |

| Integrated Components | 2-step air filter, type Europiclon, dust capacity 200 g |

SICK GM700 SLV4-2 Purge Air Unit, 2BH1300

Gas, Liquid & Bulk Solids Sensors, Analysers & Detectors from SICK

ELECTRICAL & PROCESS INSTRUMENTATION EQUIPMENT

FOR EXPLOSIVE ATMOSPHERES & Hazardous Areas

Thorne & Derrick are Specialist Distributors of Hazardous Area & Explosion Proof Equipment with IECEx & ATEX Certifications to the onshore and offshore oil, gas, petrochemicals and process industries.

Key Product Categories: Control Panels | Plugs & Sockets | Isolators | Enclosures & Junction Boxes | Lighting | Control Stations | Motor Starters | Heat Trace Cables & Systems | Gas Detection & Detectors | Fire Detection & Detectors | Heat Detectors | Electrical Heating & Heaters