December 2022 VISION!

Published 08 Dec 2022

Welcome to our industry bulletin – VISION.

So what is VISION?

VISION is our monthly round-up of industry news, projects, videos, technical tips, training information, webinars and career opportunities from Thorne & Derrick. Take a moment to Follow Us on LinkedIn to receive future VISION.

A Record-Breaking Year!

Thorne & Derrick celebrate A Record Sales YEar!

We celebrate our most successful year to date at T&D with a fantastic night at the South Causey Inn. Thank you to our Managing Director, Richard Derrick and Business & Development Manager, Terry McDonald for organising the event.

Chris Dodds, Sales & Marketing Manager said: “What a year, what a night but most importantly what a TEAM. Special thanks to all of our Customers & Suppliers across the whole business for making this our most successful since 1985.”

CHEERS! Thorne & Derrick Celebrate Record Sales Year

We celebrated the occassion with a glass of champagne and a video call with our Bristol team; before heading out to a local restaurant for their outdoor dining option.

In The News

The UK government announced in November that businesses will be given an additional two years to apply new product safety marking. While business can already use the UK Conformity Assessed (UKCA) marking for their products, the government has said it will continue to recognise the CE marking until 31 December 2024.

The main updates:

- Government to continue to recognise the CE product marking in Great Britain for a further 2 years, allowing business to use either UKCA or CE markings

- move will cut costs for businesses and remove potential disruption

- future product marking plans to be reviewed to minimise costs and burdens for business in the longer term

The deadline for businesses to use the UKCA marking has been delayed several times, the latest of which had been set for the end of this year. However, the UK government has said the difficult economic conditions created by post-pandemic shifts in demand and supply, alongside the war in Ukraine and the associated high energy prices, means it does not want to burden business with the requirement to meet the 31 December 2022 deadline.

Business Secretary Grant Shapps said: “The government is determined to remove barriers to businesses so they can get on with their top priorities, like providing quality customer service, enabling growth and supporting their staff.

“This move will give businesses the breathing space and flexibility they need at this crucial time and ensure that our future system for product safety marking is fit for purpose, providing the highest standard for consumers without harming businesses.”

The government is also reviewing the wider product safety framework to support manufacturers, ensuring we minimise the burdens on business while keeping our system up to date with new innovative methods such as e-labelling.

This package will give thousands of businesses, including electronics and lift manufacturers, additional time to focus on delivering growth and creating jobs, while giving them flexibility in how they meet their legal obligations.

There will be different rules for medical devices, construction products, cableways, transportable pressure equipment, unmanned aircraft systems, rail products, and marine equipment. Government departments responsible for these sectors are making sector specific arrangements.

INDUSTRY EVENTs

Touring The Wilton International Chemical Site

Thorne & Derrick employees visited the Wilton Centre In November, to tour the chemical processing & manufacturing site and learn more about the Net Zero Teeside Project.

Wilton International is a 2,000 acre, multi-occupancy manufacturing site located within Teesside Freeport and in the heart of Teesside’s industrial area – home to one of the UK’s leading process manufacturing clusters. The Teeside region in the north of England has a proud industrial heritage and home to a diverse cluster of industrial, power and hydrogen companies. These businesses, employing thousands of people, all aim to decarbonize their operations to help the UK reach net zero by 2050.

It was interesting to see each plant in person, as well as the onshore converter station (currently under development) which will be used to power part of Dogger Bank and Sofia Wind Farms.

Visiting The Wilton International Chemical Processing Site

Net Zero Teesside Power (NZT Power) is a first-of-a-kind fully integrated gas-fired power and carbon capture project and a key driving force behind plans to make Teesside the UK’s first decarbonized industrial cluster. NZT Power’s proposed combined cycle gas turbine electricity generating station will have an electrical output of up to 860 megawatts (MW) of low carbon electricity, enough to power up to 1.3m homes per year.

Sembcorp Energy UK is a leading provider of sustainable solutions, supplying Wilton’s major industrial businesses with secure and reliable supplies of electrical power, steam, water, and other services, using greener, more sustainable power generating facilities. Sembcorp works in supporting the UK’s transition to Net Zero.

PROJECTS & NEWS

Thank you to Jamie Mann, product sales manager at Exheat, for visiting our offices for an end of year catch up and to introduce yourself to the newest members of our team. It was great to dicuss our working relationship and how Thorne & Derrick can work closer together with Exheat in the New Year to achieve further growth!

As winter comes into full swing, our range of commercial and industrial heating solutions are ideal to help protect your plant during the cold months.

In addition to the Exheat range of air warmers and fan heaters, Thorne & Derrick can service requirements for hazardous area immersion heaters for Zone 1 and Zone 2.

T&D recently supplied a selection of immersion heaters to a local specialist of the supply and maintenance of pressure washers and accessories. Exheat HBY rod-type industrial immersion heaters offer a cost effective heating solution for commercial and industrial hot water cylinders, process tank heating, cooling tower frost protection and other applications which are non-corrosive to the materials of construction.

The EXHEAT HB range of screwed or flanged immersion heaters can be supplied with an adjustable thermostat suitable for certain applications. Typical applications for the EXHEAT HB rod-type industrial immersion heater include hot water storage tanks, frost protection and boiler equipment.

For this application we supplied the following heater models:

- HBY-916-A-240/415V | 240/415v, 1/3Phase, 9kW, Immersion Heater

- HBY-616-A-240/415V | 240/415v, 1/3Phase, 6kW, Immersion Heater

Contact Thorne & Derrick for further information on our heater range | Fan Heaters | Immersion Heaters | Line Heaters | Electrical Heaters

Sub-Zero Temperatures are here ❄

Temperatures are now dropping rapidly in the UK, which can inevitably cause disruption to operations and cost thousands of pounds in lost down time.

The Met Office has issued a series of weather warnings across the UK this week, and advises us to brace for hazardous conditions as Arctic winds bring ice and sub-zero nights across the country.

Thorne & Derrick understand that prolonged periods of low ambient temperatures can bring operations to a standstill. As experts in heating solutions for use in industrial & explosive atmospheres, our team have the knowledge & expertise to help clients prevent unnecessary down time this winter.

Protect your plant from the effects of cold weather with a preventative action plan. Thorne & Derrick hold the largest UK stocks of frost protection & winterisation equipment to help keep your plant and personnel operational during the winter months.

We can provide overnight delivery of Trace Heating Cables at the most competitive prices to guarantee frost protection of your pipelines and mechanical services.| Ask About Our Heat Trace Design Service.

T&D also hold large UK stocks of a wide range of electrical heating jackets , to heat up drums and IBC containers from 25L-1000L protecting the contents from freezing or solidifying.

Contact us to design your custom heating solution

T&D Service A Global Energy Partner

Following several intense weeks of challenging technical qualification and specification support, Thorne & Derrick are delighted to have secured the Purchase Order for the supply of MV Cable Terminations, Cable Glands, Containment & Accessories for a new major Oil & Gas project to Petrofac.

Petrofac, are a world-leader in the design, build and construction of world-class energy facilities. As an Approved Vendor since 2014, the supply of this equipment adds to our excellent track-record and successful relationship with the company.

Thorne & Derrick stock and distribute a large portfolio of equipment for the Oil & Gas industries, including hazardous area certified equipment for heat, light, power and ventilation of your plant.

Repair & Joint Cables with ZONE 2 CABLE JOINTS

Pictured below: 400 cable joints passing out the warehouse, destined for Nigeria LNG Limited. These cable joints (type LVI3), manufactured by 3M and stocked by Thorne & Derrick, will be used to repair, extend and joint cables exhibiting a mix of sheath damage and armour corrosion.

Our Technical Submission was approved by the end-user on the basis of the Type Test Report from 3M Electrical, evidencing the ability of the Jointing System to withstand aggressive hydrocarbons in Zone 2 hazardous areas during normal service operations. The client also required cable joints that do not emit halogens in fire conditions. Demonstrable asset life of the joint is equal to that of the cable; so power distribution is reliable.

3M LVI-3 hazardous area resin cable joint kits are designed to be used for multi-core, armoured polymeric, LV energy cables in hazardous areas – the cable joints are suitable for both wire braided (galvanised steel wire braid GSWB) and wire armoured (galvanised steel wire armour SWA) cables, including XLPE and PILC cables with lead sheath.

The cable joint shell and resin is flame retardant, hydrocarbon resistant and halogen free.

Thank you again to Kate Palmer-Randle for the customer project support and world-class logistics.

Marechal Gain UKEX Certification

MARECHAL ELECTRIC IS NOW UKCA/UKEX CERTIFIED!

Following Brexit, moving industrial and explosion-proof Low Voltage (LV) products between the UK and countries still part of the EU is slightly complex. Although there have been further updates on UKCA requirments, manufacturers serving the UK market will still be required to place a UKCA marking which will be mandatory from the 1st of January 2025.

Marechal have anticipated and reacted to the changes, and can confirm that all products concerned by the new regulation are already certified!

As a worldwide provider of Low Voltage (LV) solutions, Marechal is directly impacted by these new requirements. Their approach to comply with the new UK regulation is detailed below.

Marechal has undertaken actions on two main topics: customs administrative formalities and regulatory requirements related to UKCA marking. What follows details how Marechal has fulfilled the regulatory requirements.

The Marechal group manufactures plugs and sockets-outlets as well as distribution boxes for industrial and Ex environments. For these two types of products, the group has worked on separate actions.

LV industrial electrical equipment requires:

- a UKCA marking

- a self-declaration of conformity

Ex-proof equipment requires:

- a UKCA & UKEX marking

- a self-declaration of conformity

- a UKEX certificate delivered by a UK certification body or a ATEX certificate (if issued before 2023)

DECONTACTOR™ is a MARECHAL® technology used on most plugs and sockets. It uses silver-nickel butt contacts and specific spring-loaded terminals to provide exceptional connection performance and disconnection under load up to 250 A in complete safety.

The certification of the quality system remains based on European ATEX certification. The UK product certification is a transfer of certification to the new UK requirements.

Terminology Explained

Every industry has its own language, terms and acronyms. Below is a selection of the common terms in use in the Explosion industry today and how they are employed in current directives.

This month we focus on Dust Extraction and the risks involved.

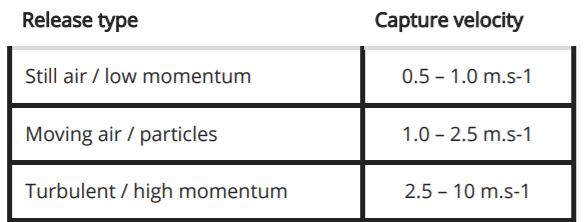

Dust extraction is important to limit fugitive emissions and it should be routinely monitored to ensure satisfactory performance. In addition, the level of ventilation should ensure that the dust-air concentration does not routinely exceed 25 % of the lower explosive limit LEL or minimum explosible concentration MEC). The ‘capture velocity’ is also important and this depends on the level of air movement in the region of interest.

Dusts, which are not removed by mechanical extraction ventilation, settle out, at a rate depending on properties such as particle size, into layers or accumulations and account has to be taken of the fact that dilute or small continuous sources of release (in time) may produce a potentially hazardous dust layer.

Principally, three risks are presented by dust layers:

Risk 1: A primary explosion within a building may raise dust layers into clouds, and cause secondary explosions more damaging than the primary event. Dust layers should always be controlled to reduce this risk.

Risk 2: Dust layers may be ignited by the heat flux from equipment on which the layer rests. The risk is of fire, rather than explosion, and this may be a slow process.

Risk 3: A dust layer may be raised into a cloud, ignite on a hot surface and cause an explosion. In practice, dust cloud ignition temperatures are often much higher than layer ignition temperatures. For example, Paper fines have a layer ignition temperature of 210 – 275 °C, but a cloud ignition temperature of > 450°C.

These risks depend on the properties of the dust and the thickness of layers, which is influenced by the nature of the housekeeping. The likelihood of a layer catching fire should be controlled by the correct selection of equipment and effective housekeeping.

Merry Christmas From T&D!

Thank you once again to our supply chain and customers for helping us to achieve a record-breaking year at Thorne & Derrick. We hope you have a fantastic Christmas and New Year, and we look forward to working together in 2023.

VISION! BY,

EXPERTS IN EQUIPMENT FOR EXPLOSIVE ATMOSPHERES

LEADERS IN ATEX INNOVATION TO THE HAZARDOUS AREA INDUSTRIES

Thorne & Derrick are leaders in the development and distribution of Product Innovations that deliver significant improvements to clients plant, people and operational safety in the explosive atmosphere industries.

Your proactive problem solvers experienced in succession planning for the replacement of obsolete, non-conformant and legacy equipment in hazardous areas.

Your first-choice provider of innovative and competitive solutions to ensure ATEX & IECEx Compliance for Hazardous Area Electrical, HVAC & Process Instrumentation Equipment to UK and international projects.

Control Panels | Plugs | Isolators | Enclosures & Junction Boxes | Lighting | Control Stations | Motor Starters | Heat Trace | Gas Detection | Flame Detection | Process Instrumentation | Process Heating | Ventilation Fans | Security Access Control