Gas Detection – 5 Points To Protect People & Plant Against Gas Hazards

Published 24 Jan 2017

- By Chris Dodds : estimated reading time 9 minutes

Gas Detection Systems

Gas detection systems have been used for centuries in various forms (from feathered to infrared) and today are an essential element of plant safety throughout industry – gas detectors save lives, protect workers and safeguard property.

However if they are not installed, commissioned or maintained properly they will not provide the protection against dangerous toxic and flammable gases.

The risks of not having adequate gas detection systems and procedures in place can be catastrophic resulting in serious harm or death to personnel and significant financial damage done to equipment.

How do you ensure that your gas detection system will respond as expected when you need it most? Do you know if it is working right now?

In many industries, the installation and correct placement of gas detection equipment is a key part of the safety plan for reducing risks to personnel – industries such as oil and gas are at the most risk from explosive gases due to the nature of the products they are transporting, storing and refining.

T&D look at the 5 main best practices that you should consider in the installation, commissioning and maintenance of your gas detection systems.

Once upon a time underground miners used canaries to test air quality in mines – today gas detection is provided by instruments manufactured by market-leaders

1. Adequate gas detection coverage

There is no legislation or specific standards governing gas detector location as there are for fire detection systems there are however general guidance documents including:

- BS EN 50073:1999: Guide for selection, installation, use and maintenance of apparatus for the detection and measurement of combustible gases or oxygen – replaced by BS EN 60079-29-2:2015

- IEC 60079-29-2 2015 : Explosive atmospheres – Part 29-2: Gas detectors – Selection, installation, use and maintenance of detectors for flammable gases and oxygen.

Ensuring the gas detector in use, whether it is portable or fixed, provides adequate gas detection coverage for the assets being protected. With fixed gas detectors this is often decided during the initial design and survey of the site to be monitored.

For portable gas detectors, this typically means ensuring the gas detector is located within the breathing space of the user. For retrospective installations, it is vital to ensure the gas detectors are given adequate space and will come into contact with any gas that may be present.

For the detection of heavier gases, such as hydrogen sulphide (H2S), it is essential to ensure the gas detector is placed close to ground as H2S gas is heavier than air – if the detector is located at high level then it will fail to detect gas.

Portable Gas Detection – Personal & Area Monitoring

Portable gas detectors are often subject to extremely diverse working conditions and environments – the many different applications require solutions tailored to the individual requirements and respective application conditions.

Portable gas detection can be distinguished between personal and area monitoring, confined space entry and leak detection:

- Personal Monitoring – the gas detection instrument should warn the wearer in his/her immediate working area. These detectors are typically worn on work clothing and therefore typical basic requirements include a high degree of comfort, robustness and reliability. The wearer will require continuous detection for single gases or multiple gases.

- Area Monitoring – area monitoring is the monitoring for gases in a specific working area with active workers present. The device is located in a central area to provide maximum gas detection coverage and monitor the whole working area. For area monitoring continuous measurement devices for multiple gases should be used.

- Confined Space Entry – in many working areas where maintenance or repair work is required to, access to confined spaces is needed. With limited space, often a lack of ventilation and the presence of harmful and dangerous gases, a clearance measurement is required before entry. After a successful measurement of the confined space, the same device can then continue to be used for ongoing confined space gas detection requirements.

- Gas Leak Detection – leakages can occur anywhere where gases or liquids are stored or transported. It is vital to identify these leakages immediately to reduce the risks to people and prevent as much as damage as possible. Detection instruments with corresponding pumps must have rapid response times in order to detect even slight changes in concentration.

2. Proper air flow to the gas detector

If the gas detector is being installed in a dock mount, it is vital to ensure there is adequate airflow so that it is not in a dead zone. Proper airflow to the gas detector ensures that new air that may contain harmful gas can be detected.

It also means any stagnant air that may set off the gas detector erroneously will not linger around the detector causing a false alarm. In addition, any air inlet filters should be clean to allow unrestricted air flow into the detector.

The height of the gas detector installation must be considered also as many gases are heavier than air and therefore if the gas detector is installed too high up, gases such as refrigerant or Freon gases will settle lower in the room and not be readable by the gas detector.

3. Proper device calibration

Gas detectors should be fully calibrated upon initial installation and then checked annually under a routine maintenance schedule. Some gases are sensitive to different conditions such as altitudes and therefore require calibration before use in a new environment.

Without adequate calibration, gas detector devices do not provide the protection and alert users as they should. Calibration is effectively a product reset against a known concentration of target gas, in a balance of synthetic air or nitrogen and is required for a number of reasons.

If the detector has been subjected to adverse conditions such as a change in temperature, sensor poisoning through exposure to contaminants like silicone and solvents, or exposure to high gas concentrations this can result in a change to which the detector responds to certain gases. In addition, mechanical shock or stress and sensor age can affect performance.

The calibration is a two step procedure:

- The instrument is zeroed in fresh air, synthetic air or a nitrogen background so the readings equal clean air.

- The second step is to expose the gas detector to calibration gas that contains known levels of the gases the detector is known to measure.

Calibration is not required as frequently as bump testing which should be carried out before each use.

4. Routine maintenance & bump testing

Routine maintenance of gas detectors can be classified as a full calibration, bump testing and a general inspection of the devices. The frequency of when each should be carried out varies.

Bump testing of gas detectors should be carried out regularly and ideally before each use. The bump test is a much shorter test than the full calibration and ensures the gas detection device is functioning as expected.

The OSHA defines the bump test as: “a qualitative function check in which a challenge gas is passed over the sensor(s) at a concentration and exposure time sufficient to activate all alarm settings.”

Put simply, this test verifies the performance of the of the gas detector and ensures the sensors are responding to their target gas as expected. The OSHA also confirms that the bump test should be carried out “before each day’s use in accordance with the manufacturer’s instructions”.

As portable gas detectors are an important part of a workers’ daily safety equipment, bump testing ensures that equipment is safe for use and performing at the standards expected. Only fully functioning gas detectors can provide detection and protection against deadly gases.

Eventually, all gas detector sensors will come to the end of their life and some can reach this point suddenly. The product longevity depends upon the application conditions and environmental influences.

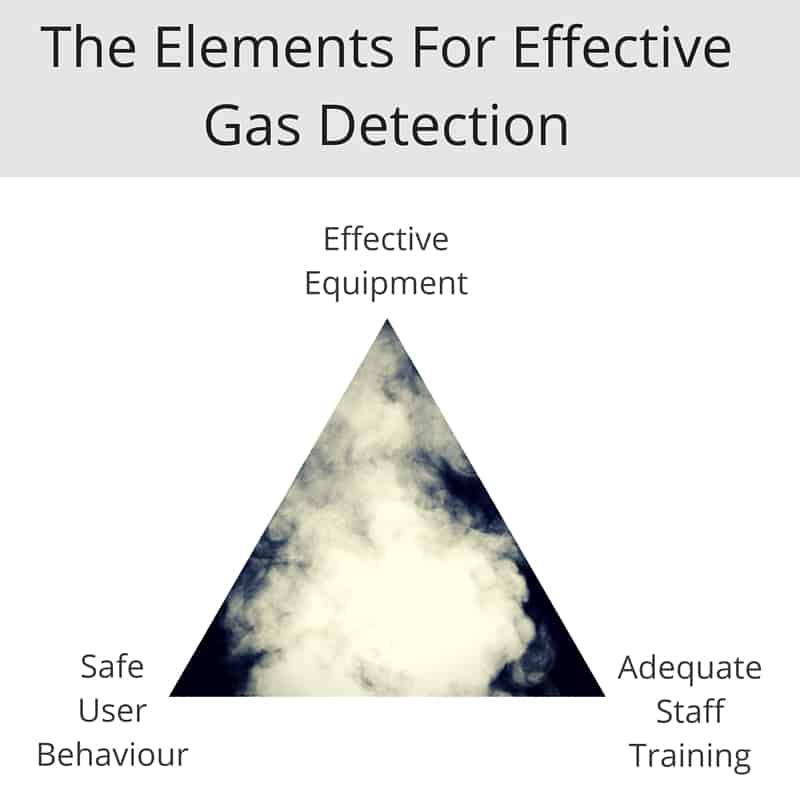

5. The Elements Of Effective Gas Detection

Reliable equipment, safe user behaviour and adequate training are the three components needed for effective gas detection. Staff training is just as important to gas detection as having the appropriate equipment. If staff are unaware of how to effectively and safely operate and calibrate their gas detection equipment then they put their own lives and colleagues well-being at risk.

Effective staff training is a key part of effective gas detector usage and maintenance which can often be overlooked. As a minimum, staff should have basic training and understanding of the nature of any likely gas hazards and how to minimise the chances of an encounter with these gases.

Gas monitors display information about the type of gas present and the levels of that gas. It is vital that personnel working around gases understand the information being shown, how to access it and what to do if a gas alert sounds.

Staff must also know the benefits of bump testing and calibration and how to carry out such servicing. Similarly, employees should be trained on how to fully service and maintain gas detectors and should always be carried out by someone who fully understands gas detection equipment and how to ensure safe operation in hazardous areas.

The effectiveness of any gas detection equipment is significantly impaired if it is not maintained properly and without adequate staff training the protection of personnel is always likely to be compromised.

The Three Elements Required For Effective Gas Detection

Hazardous Area Gas Detection

Many industrial processes and environments frequently involve flammable substances and particles including gases and vapours. For prevention purposes these areas are classified as Ex-areas or zones and are graded by the likelihood of gas being present.

ATEX European Hazardous Area Certifications

Only gas detection equipment that has been certified as suitable for use and is equipped with explosion protection in hazardous areas can be used. Explosion protection is regulated globally and the basic standards are are:

- IEC (International)

- CEN, CENELEC (Europe)

- NEC 505 (North America)

The ATEX 95 European directive is mandatory in the European Union and has been since 2003. This directive sets out the standards that equipment and protective systems for use in potentially explosive atmospheres need to fulfil in order to meet Essential Health and Safety Requirements (EHSR).

More Reading

- Methane CH4 Gas Detection – See How Crowcon Detects CH4 Gas Levels

- Gas Detection In The Food Processing Industry Using Portable Gas Detectors

Flame, Heat, Gas Detectors & Detection Systems

![]()

Hazardous area industries including offshore oil/gas platforms and FPSOs, onshore oil refineries, processing plants, pipelines, storage farms and LPG/LNG plants all utilise or produce a wide range of hazardous flammable liquids and gases that can be detected using correctly specified flame and gas detectors.

Detecting toxic and flammable gases requires the detectors to be classified and certified according to the specific IECEx or ATEX standard – we distribute flame and fire detectors manufactured by Spectrex to operate in the harshest environmental conditions including self-contained stand-alone devices designed for direct connection to control and alarm systems or automatic fire extinguishing systems.

Our range of Hazardous Area Fire & Gas Detection System products also includes Explosion Proof Warning Systems & Hazardous Area Lighting – comprehensive range of intrinsically safe, flameproof and explosion proof alarm sounders, sirens, bells and horns, loudspeakers and beacons.

♦ LV Power Products | Junction Boxes & Enclosures ATEX | Plugs ATEX | Control Stations ATEX | Isolators ATEX

Thorne & Derrick | Detecting Flame | Heat | Gas

Experts in Equipment

for Explosive Atmospheres

FOLLOW US

Follow our Showcase Page on LinkedIn to receive hazardous area product innovations, industry news, whitepapers, videos, technical tips and training webinars for professionals involved in the explosive atmosphere industries.