Hazardous Area Lighting – Emergency Lighting & Luminaires (3 Essential Factors)

Published 09 Jul 2019

Hazardous Area Lighting – Emergency Lighting & Luminaires (3 Essential Factors)

-

uploaded by Chris Dodds - Thorne & Derrick Sales / Marketing Manager

Emergency Lighting For Hazardous Areas

Emergency Ex lighting plays an important role in maintaining the safety of hazardous area zones and locations, and the well-being of those who work in them, by providing back-up illumination and lighting when the primary power source fails.

In this article, attributed to Raytec SPARTAN, we take a closer look at how the latest ‘intelligent’ emergency hazardous area lighting can improve performance of emergency systems, ultimately increasing safety and reducing risk on-site.

Emergency Lighting & Luminaires Zone 1 & Zone 2

What Is an Intelligent Emergency Lighting?

‘Intelligent’ emergency lighting features a built-in microprocessor which automatically cycles the emergency batteries, checks the health status of the hazardous area lighting and communicates it via an LED indicator. The entire process is automated, unlike conventional emergency lighting where checks and battery cycling are a manual process.

- Commissioning test

Three charge and discharge cycles are carried out automatically at the point of the initial installation. This is essential in ensuring the battery maintains its full capacity.

- Functional test

Occurring every seven days, this is a shorter test lasting just a few minutes which checks the function of the battery, luminaire and power supply.

- Self-test

A random test occurring every three months, this more rigorously tests the battery’s capacity and the lighting overall condition. Critically, if the battery is not operating at full capacity, the light fitting can also perform self-recovery to restore optimum performance.

Without the light fittings ability to automate testing, these processes would otherwise have to be carried out manually. As well as using up time and resource, this could also potentially cause disruption to site.

To improve ease of inspection, the new lighting communicate the current health of the luminaire via a tri-colour LED indicator. This system communicates when the unit is going through one of the testing procedures and highlights the health of the lighting.

Hazardous Area Lighting

| LED Indication | Condition |

| Battery charged and PSU OK | |

| Emergency mode activated | |

| Function Test | |

| Self-test | |

|

Commissioning |

|

Fault – further troubleshooting required |

Why Do I Need

Intelligent Emergency Lighting?

To operate effectively (by providing optimum levels of light and duration in emergency scenarios), an emergency lighting’s battery must be regularly checked and tested to ensure there is no degradation in its capacity. Further conditioning is also required to maintain its optimum performance.

Given that conventional emergency lighting rely on human intervention in the process of routinely monitoring, checking and testing, there is an associated risk of human error or neglect. If the luminaire is not properly tested and maintained there could be serious implications on the performance of the hazardous area lighting when an emergency scenario occurs.

Automating the process by introducing intelligent emergency lighting effectively eliminates this risk, increasing reliability of the emergency network and improving overall site safety. A reduction in the time and cost of maintenance is another associated benefit.

Hazardous Area Emergency Lighting

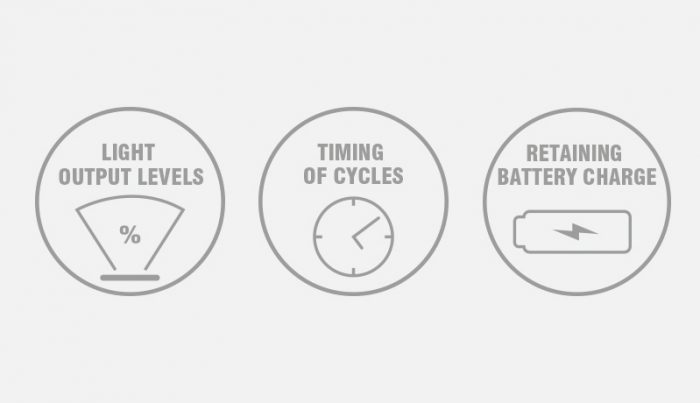

3 Things to Consider When Choosing an Intelligent Emergency Lighting

1. What level of light output will your intelligent emergency lighting provide once an automatic test begins?

This is an important consideration. If the emergency lighting can only operate in the hazardous area at a reduced output during testing procedures or battery cycling, parts of the site could unexpectedly lose significant levels of light, albeit for a temporary period.

If this occurs at a critical moment it could cause disruption or create a serious safety risk. In contrast, a lighting capable of maintaining 100% light output during testing will continue to provide the same constant level of performance.

2. When will the automatic testing occur?

As batteries are cycled, their charge is drained and then recharged to ensure they are operating at full capacity. It is important to consider when and how these cycles will occur, and the impact the timing of them could have.

If all lighting on-site were to enter a testing cycle at roughly the same time, performance of the entire network would be compromised if an emergency scenario occurred while this was ongoing; with battery charge levels depleted, output duration is stunted.

An intelligent emergency lighting should therefore conduct testing randomly to ensure there is never a significant proportion of luminaires undergoing a testing cycle at one time. This will help to avoid any unexpected duration shortages should an emergency scenario occur.

3. What happens if an emergency scenario occurs when a test is taking place?

Even if testing does occur randomly, having even one lighting on-site which is completely discharged could present a safety risk. Allowing a battery to discharge completely presents a risk of total light loss if an emergency scenario occurs at the end of a discharge cycle; with no charge in the battery, there is no power to the luminaire in emergency mode.

Crucially, if some reserve capacity is retained, and the batteries are only discharged to around a third of their capacity, at worst the lighting will still be able to provide around one hour of light in emergency mode (depending on the power / % output).

Opting for a luminaire which retains reserve capacity during testing is therefore an important consideration.

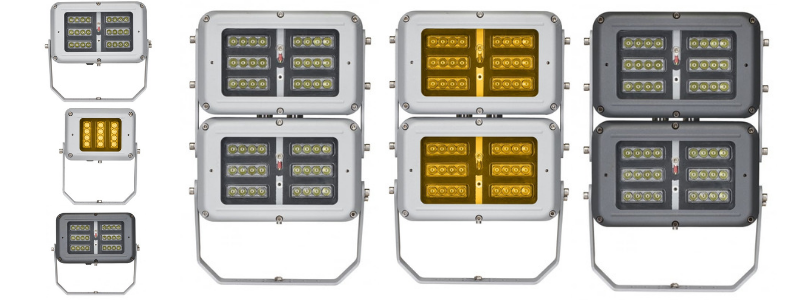

Raytec Performance Advantage

The new range of Raytec SPARTAN intelligent emergency lighting incorporate all the key features which you need to consider when upgrading to an intelligent system.

100% light output is maintained during all testing procedures, while discharge cycles occur randomly every 3 months and always retain around a third of the battery’s charge, so you’re never left with a total loss of light.

ELECTRICAL & PROCESS INSTRUMENTATION EQUIPMENT

FOR EXPLOSIVE ATMOSPHERES

Thorne & Derrick are Specialist Distributors of Hazardous Area & Explosion Proof Equipment with IECEx & ATEX Certifications to the onshore and offshore oil, gas, petrochemicals and process industries.

Key Product Categories: Control Panels | Plugs & Sockets | Isolators | Enclosures & Junction Boxes | Lighting | Control Stations | Motor Starters | Heat Trace Cables & Systems | Gas Detection & Detectors | Fire Detection & Detectors | Heat Detectors | Electrical Heating & Heaters

Trace Heating | System Design & Supply