Hazardous Area Lighting | Upgrading Fluorescent To LED Light Fittings With ATEX Certification

Published 09 Jul 2019

-

uploaded by Chris Dodds - Thorne & Derrick Sales / Marketing Manager

Hazardous Area Lighting

Upgrading Fluorescent To LED Light Fittings – ATEX Certified

Zone 1, 21 & Zone 2, 22 Gas & Dust Applications

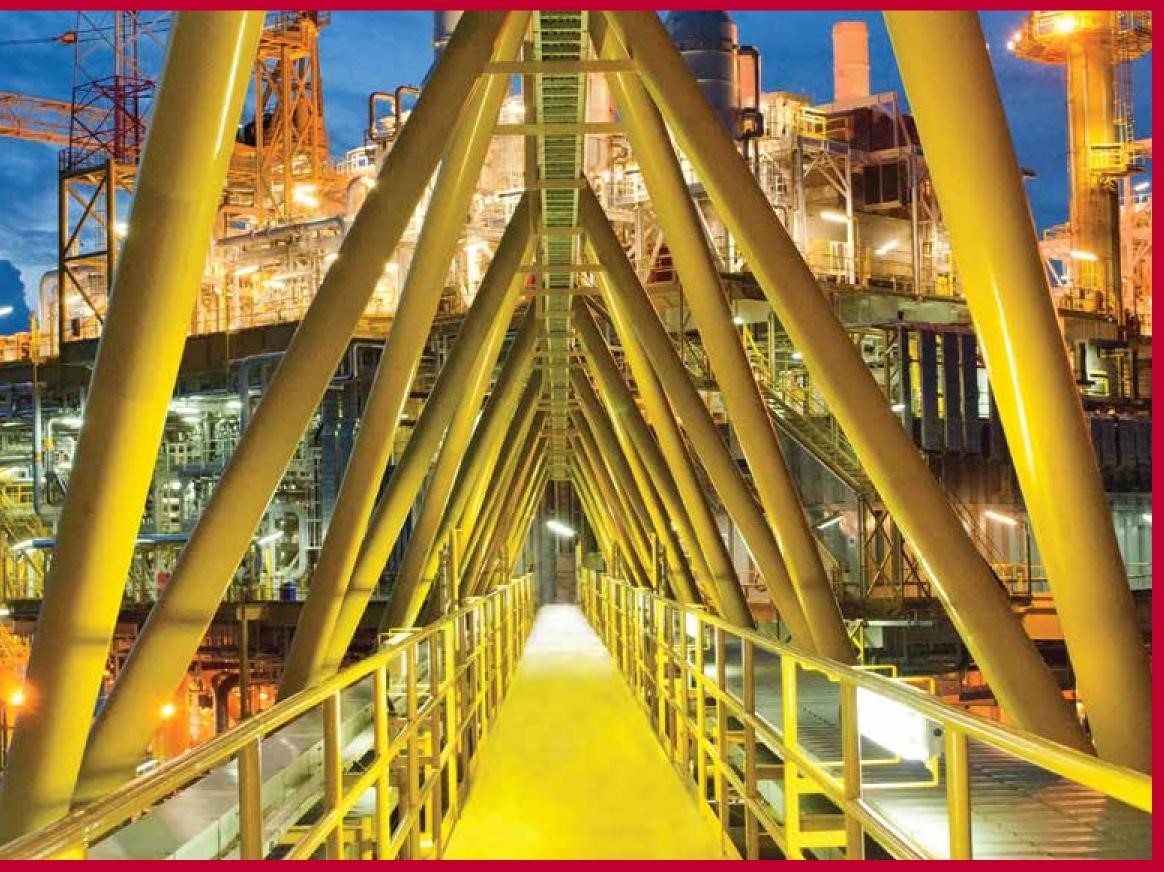

The hazardous area lighting you choose to install today will make the difference in plant safety, worker comfort and maintenance costs for years to come.

Emerson lights your way forward with the Appleton ATX FELED Series of linear LED lighting for hazardous areas with luminaires and light fittings for onshore and offshore Zone 1 and Zone 21 potentially explosive atmospheres.

Certified for use in IECEx and ATEX installations, these nonmetallic explosion proof lighting fittings equal or exceed the lighting output, quality and distribution of the Appleton FE Series fluorescent light fittings, already the proven industry standard.

Using the same footprint and mounting hardware as the Appleton FE Series, with a wide range of lumen outputs that allow for an easy retrofit of any hazardous area fluorescent light fitting installation, the FELED Series’ low profile design and functional simplicity suit practically any task or general purpose application requirement and mounting height.

For best-in-class corrosion resistance, durability and performance, look to the light fitting you can trust. Appleton FELED Series light fittings, distributed in the UK by Thorne & Derrick International.

LED Light Fittings

FELED lighting make it easy to replace existing fluorescent fixtures because they feature the same housing and mounting accessories as original FE fluorescent fittings.

Light fittings are available in light output from 2,500 to 7,000 lumens. In the rare event maintenance is needed, the lens can be quickly removed to access the internal components, while the specially designed hinged cover speeds up the process of replacing drivers, or diffusers when carrying out hazardous area lighting inspections and routine maintenance.

Appleton ATX FELED Series Nonmetallic LED Lighting – Zone 1, 21 & Zone 2, 22

|

|

|

| Fixture easily accessed with a standard hex key | Latch assembly and elastomer gasket seals against water and dust ingress (IP66) | Hinged polycarbonate lens for easy maintenance |

Easy To Specify Light Fittings

FELED fittings are available in a wide range of lumen outputs to suit a variety of hazardous area Zone 1 and Zone 21 task and general purpose lighting requirements. Compared to fluorescent fittings, the lights deliver increased energy efficiency, lower maintenance costs and greater operational uptime. With a 3-hour emergency option available on the FELED5 versions, the FELED Series of light fittings provides assurance that your hazardous locations will be safely illuminated.

Easy To Install

For sites that already have Zone 1 fluorescent fittings, the FELED Series retrofits into the existing mounting hardware. Light fittings can be mounted vertically or horizontally, using pole, wall, ceiling, hinged or chain mount options. The terminal block provides ample working room, with screw type terminals for simple, secure wiring.

Easy To Maintain

Maintenance access requires only a hex key and straight blade screwdriver. The patented release mechanism and hinged cover are designed to ensure hassle-free maintenance and installation. Positive safety switch disconnects power to LED’s and driver upon unlocking the lens to allow maintenance in hazardous area locations. The LEDs are rated for 60,000 hours of operation at 55 °C (131 °F), and last far longer at lower temperatures. Field-replaceable parts are available to extend hazardous area lighting performance even further.

Retrofitting Made Easy

The FELED Series of light fittings includes units that provide lighting distribution comparable to the Appleton FE Series fluorescent fittings, with additional models that offer even more application possibilities. Choose the diffuser option for the greatest uniformity, least amount of glare, best vertical illumination and safest photobiological rating.

LED Hazardous Area Light Distribution Comparison

The hazardous area lighting simulation below compares three rooms, each with a single light fitting mounted at 4.5 m (15 ft); a fluorescent 1.39 m (4.56 ft), a 0.79 m (2.58 ft) FELED4, and a 1.39 m (4.56 ft) FELED5. The photometric simulated colour rendered images below demonstrate the seamless transition with either size light fitting.

Light Distribution Comparison

The FELED Series of fittings saves energy while maintaining equivalent required illuminance levels and uniformity to the FE Series fluorescent light fittings

Hazardous Area Lighting Performance

| Hazardous Area Lighting Part Number | Size (Meters) | Size (Feet) | Power Consumption (Watts) | Light Output (Lumens) | Eav (Lux) Floor | Emin (Lux) Floor | Emax (Lux) Floor | Emin / Emax |

| FEB236BUSA | 1.39 | 4.56 | 72 | 4423 | 31 | 16 | 55 | 0.53 |

| FELED4CBDSAD | 0.79 | 2.58 | 32 | 3600 | 28 | 11 | 73 | 0.40 |

| FELED5CBDSAD | 1.39 | 4.56 | 38 | 4650 | 30 | 12 | 77 | 0.41 |

The table below provides a cross reference between the FE Series fluorescent fittings and the FELED Series light fittings.

Fluorescent to LED Retrofit Guide

| FE Series Fluorescent Fittings | Lamp Used | Lamp Output (Lumens) | System Efficiency | System Output (Lumens) | Effective LED Output Required for Replacement (Lumens) | Normalized Output (Lumens) | FELED Series | FELED Series LED Light Fittings (Lumens) |

| FEB218BUSA | 2X 18 W | 2400 | 85% | 2040 | 1836 | 1800 | FELED3C | 2850 |

| FEB318BUSA | 3X 18 W | 3600 | 68% | 2448 | 2203 | 2200 | FELED3C | 2850 |

| FEB136BUSA | 1 X 36 W | 2750 | 89% | 2448 | 2203 | 2200 | FELED3C | 2850 |

| FEB236BUSA | 2 X 36 W | 5500 | 80% | 4400 | 3960 | 4000 | FELED4C / FELED5C | 3600 / 4650 |

| FEB158BUSA | 1 X 58 W | 4325 | 87% | 3763 | 3386 | 3300 | FELED5C | 4650 |

| FEB258BUSA | 2 X 58 W | 8650 | 77% | 6661 | 5994 | 6000 | FELED7C | 7050 |

| FEB358BUSA | 3 X 58 W | 12975 | 66% | 8564 | 7707 | 7500 | FELED7C | 7050 |

Fluorescent To LED

The Smart Upgrade

Energy Savings

LED lighting provide far greater lighting efficacy compared to traditional hazardous area lighting sources, including fluorescent light fittings, the previous efficiency leader.

Maintenance Savings

Fluorescent lamps last an average of 13,000 hours, or 1.48 years, in continuous use. By contrast, LED light fittings are rated for 60,000 hours and can exceed 200,000 hours depending on ambient temperature.

Safety

LED lighting provide instant-on and cold-start capabilities without end-of-life degradation or premature failures due to frequent cycling, with a photobiological safety rating of RG0.

Energy Comparison

Compared to the FE Series fluorescent fittings, the FELED Series of LED linear type light fittings saves as much as 57% in energy costs.

FE Series Fluorescent to FELED Series LED Lighting Energy Comparison

| FE Series Fluorescent Light Fittings | Lamp Used | Power Consumption (Watts) | FELED Series LED Light Fittings | Power Consumption (Watts) | % Energy Savings |

| FEB218BUSA | 2 x 18 W | 36 | FELED3 | 27 | 25% |

| FEB318BUSA | 3 x 18 W | 54 | FELED3 | 27 | 50% |

| FEB136BUSA | 1 x 36 W | 36 | FELED3 | 27 | 25% |

| FEB236BUSA | 2 x 36 W | 72 | FELED5 | 38 | 47% |

| FEB158BUSA | 1 x 58 W | 58 | FELED5 | 38 | 34% |

| FEB258BUSA | 2 x 58 W | 116 | FELED7 | 63 | 46% |

| FEB358BUSA | 3 x 58 W | 174 | FELED7 | 63 | 64% |

Dramatically Reduce Your Hazardous Area Lighting Costs

When retrofitting a 2 lamp FEB236BUSA light fitting, you can achieve break even on your investment in approximately 8 months. When evaluating lighting systems for hazardous area locations, consider both the total system power consumption and the expected lighting life, in order to evaluate energy and maintenance costs and savings.

5 Year Cumulative

| Light Fitting | Power Consumption (Watts) | Light Output (Lumens) | Yearly Energy Costs | Lamp Life (Hours) | Yearly Maintenance Costs | Yearly Total Costs | Yearly LED Savings | Yearly Savings Percentage |

| FEB236BUSA | 72 W | 4423 | 35 € | 13,000 | 23 € | 58 € | — | — |

| FELED5 | 38 W | 4650 | 18 € | 100,000 | 0 € | 18 € | 40 € | 69% |

Energy Costs = Watts x 24 (hr / day) x 365 (days / yr) / 1000 (kWh / yr) x 0.055 (Euro / kWh)

Maintenance Costs = [{2 (fluorescent lamps) x 8 (euro each)} + 22.5 (euro for installation cost for one worker)] x 3 (replacements in 5 years) / 5 (years)

Labor cost = 45 euro / hour/worker

-

Lighting ♦ Plugs & Sockets ♦ Control Stations ♦ Junction Boxes

Appleton ATX Hazardous Area Electrical Equipment

Full range of Appleton ATX Hazardous Area Products available from Thorne & Derrick stock and 5 Day Express Service:

-

- Plugs & Sockets | Zone 1 & Zone 2 Hazardous Area Plug & Sockets EX ATEX Certified

- Isolators & Safety Switches | Zone 2 Isolators & Safety Switches EX ATEX Certified

- Lighting | Zone 1 & Zone 2 Hazardous Area Lighting EX ATEX Certified

- Junction Boxes | Zone 1 & Zone 2 Hazardous Area Junction Boxes EX ATEX Certified

- Control Stations | Zone 1 & Zone 2 Hazardous Area Control Stations EX ATEX Certified

ELECTRICAL & PROCESS INSTRUMENTATION EQUIPMENT

FOR EXPLOSIVE ATMOSPHERES

Thorne & Derrick International, based in the UK, are Specialist Distributors of Hazardous Area & Explosion Proof Equipment with IECEx & ATEX Certifications to the onshore and offshore oil, gas, petrochemicals and process industries.

Key Product Categories: Control Panels | Plugs & Sockets | Isolators | Enclosures & Junction Boxes | Lighting | Control Stations | Motor Starters | Heat Trace Cables & Systems | Gas Detection & Detectors | Fire Detection & Detectors | Heat Detectors | Electrical Heating & Heaters

Trace Heating | System Design & Supply

Further Reading

-

Appleton ATX FELED Hazardous Area Lighting Zones 1 2 & Zone 21 22

Size: 648.76 KB

Appleton ATX FELED Hazardous Area Lighting Zones 1 2 & Zone 21 22

Size: 648.76 KB

-

Appleton ATX FELED – Data Sheet

Size: 538.83 KB

Appleton ATX FELED – Data Sheet

Size: 538.83 KB