Marechal Plugs & Sockets | Self Ejecting Systems

Published 18 Nov 2022

Marechal Plugs & Sockets

Self Ejecting Systems

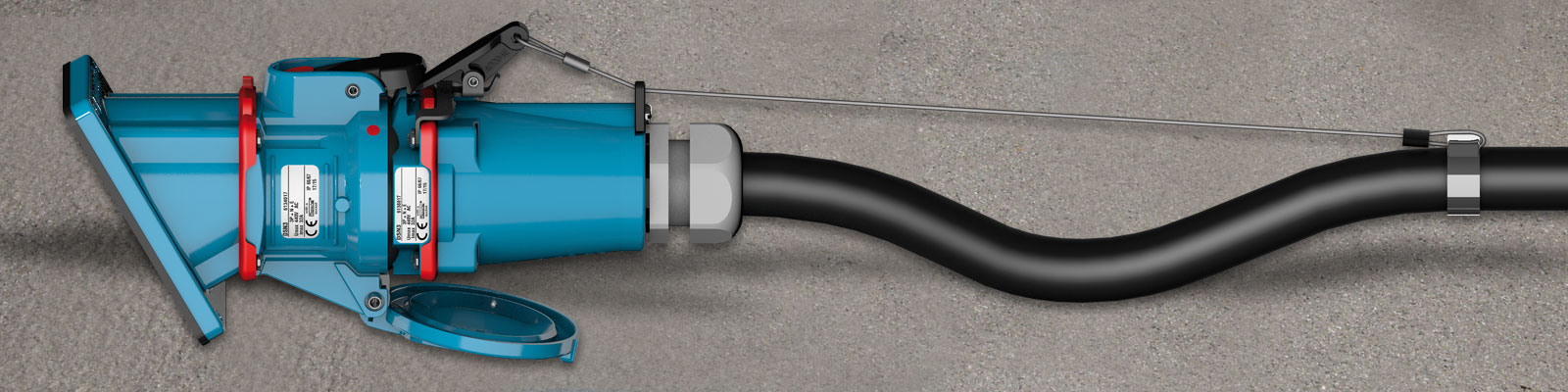

Marechal plugs & sockets are available with a self-ejecting option this ensures that they are safely disconnected when a vehicle or portable equipment is moved. As a result workers are protected from electrical hazards, equipment damage is prevented and maintenance costs are reduced.

Marechal, a world leading manufacturer of Electrical Safety Plugs & Sockets have innovated self-ejecting plugs and power connector systems designed to protect people and plant from electrocution caused by accidental or intentional disconnection of power supply.

Self-ejecting plugs & sockets avoid the need to disconnect electrical equipment, allowing a mobile device to be moved without unplugging it, or where equipment is located in high-risk areas.

Marechal Self Ejecting Plugs. B = box, Sl = sleeve, S = socket outlet, I = inlet, Me = mechanism, H = handle and C = cord.

How Do Self Ejecting Systems Work?

A Marechal plug can be ordered with self-ejecting features. When a self-ejecting female connector is ordered, the standard pawl on the connector is replaced by a shark’s fin pawl. When the device is installed, the pawl is attached to the power cable via a tension cord. Then if the connected equipment is moved, the tension cord lifts the shark’s fin pawl and the connector is ejected before damage can occur.

When a self ejecting male plug is ordered a shark’s spin mechanism is added to the plug. During installation, a tension cord is attached from the shark’s fin to the power cable. When tension develops in the power cable, the shark’s fin mechanism lifts the standard pawl on the female socket and the plug is safely ejected.

Self-ejecting connections are commonly used on truck hook-ups, cranes, railroad cars, refrigerated food carts, delivery vehicles, and other portable equipment.

Please note: That the self-ejecting feature requires modification to the socket that allows straight insertion and disconnection. Plugs and sockets modified for straight-insertion or self-ejecting are not Switch-Rated.

There are many applications where Self Ejecting Systems are a valuable asset:

- Emergency vehicles

- Road transport vehicles

- Electric boats

- Rolling heating or cooling in the food industry/canteens

- Hospitals

- Switch boards located at vulnerable places (a toll terminal for example)

Benefits

|

|

|

|

Minimise Equipment Damage

Self-ejecting plugs and sockets are designed to protect electrical system equipment from damage in the event of drive-away or drive-by snagging of a power cable. The ejection of the connector ensures there is no damage to the inlet, trailer, power cord or control panel.

Protect User: Safety First

Drive-away damage can leave trailer/mobile equipment inlets in an unsafe condition and result in live conductors being exposed on supply side/loading dock equipment, posing unexpected shock or arc flash hazards for subsequent users.

Improved Reliability & Uptime

Drive-away damage not only puts loading docks, supply trailers and other equipment out of commission until necessary repairs can be made, but may also affect the production or supply operations they are intended to serve.

Cost Reduction

One drive-away event can destroy the trailer inlet and mounting, the connector and power cable and the control panel, resulting in thousands of pounds of equipment damage and significant maintenance work for repairs.

UK HSE

Guidance Notes On Workplace Electrical Safety

“Cables, plugs, sockets and fittings must be robust enough and adequately protected for the working environment. Ensure that machinery has an accessible switch or isolator to cut off the power quickly in an emergency.”

MOBILE APPLICATIONS

| 20A / 32A RETTBOX® ONE WITH OR WITHOUT AIR |

|

|

20A / 32A RETTBOX® S WITH OR WITHOUT AIR |

| 20 A > 150 A SELF-EJECTION DECONTACTOR™ |

|

OPERATION SEQUENCE

Self-ejection systems avoid damage to the electrical installation when the mobile equipment is moved without removing the supply connection. They are designed to automatically release the mobile socket outlet or inlet thanks to a cord attached to the locking latch and the power supply cable.

DSN/DS/DXN RANGES

MECHANICAL SELF-EJECTING Systems

Fixed Electric Power Supply

Step 1: Self-ejection system at rest.

Step 2: The traction acts on the electrical cable and the rope. The ejection lever gradually raises the latch.

Step 3: The latch is fully raised by the ejection lever, causing the automatic ejection of the plug.

Thorne & Derrick, Experts in Equipment for Explosive Atmospheres, are Specialist Distributors of Marechal plugs & sockets in the UK including ATEX and IECEx certified decontactors for LV electrical power distribution.

The range of Marechal plugs and sockets are available in a range of current ratings, switching capabilities, voltage supply and hazardous area certifications (according to ATEX & IECEx) for safe use in potentially explosive atmospheres – this includes Zone 1 & Zone 2 (Gas) and Zone 21 & Zone 22 (Dusts).

Panels | Plugs | Isolators | Enclosures | Lighting | Control Stations | Motor Starters | Heat Trace | Gas Detection | Flame Detection | Process Instrumentation | Process Heating | Fans | Security Locking & Access Control