ASCO 551-553 Aluminium Valves | Ex m Encapsulated ATEX IECEx Solenoid Valves 5/2 5/3 (PV)

ASCO 551-553 Aluminium Valves | Ex m Encapsulated ATEX IECEx Solenoid Valves 5/2 5/3 (PV)

Ex m Encapsulated

Potentially Explosive Atmospheres

ASCO 551-553 5/2 5/3 solenoid Valves

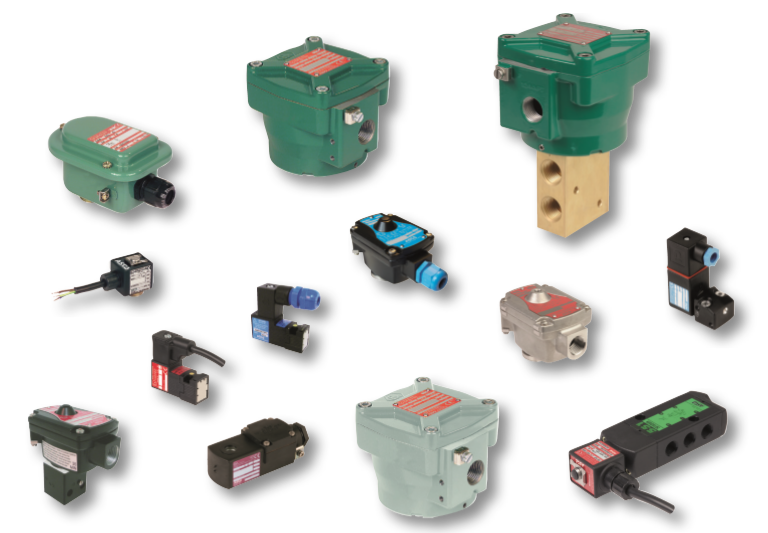

ASCO 551-553 Ex m encapsulated valves for use in potentially explosive atmospheres – in accordance with explosion protection concept type Ex m (Encapsulation). This series of solenoid valve operators are manufactured and certified for hazardous area use according to ATEX, IECEx and IEC regulations.

The monostable spool valves are manufactured and certified for hazardous area use according to IEC 61508 Standard (2010 route 2H version) and are TÜV (551 series) and EXIDA (551-553 series) certified with integrity levels: SIL 2 for HFT = 0 / SIL 3 for HFT = 1.

They are single/dual solenoid valves, which are pilot operated, have an aluminium body and are 1/4 and 1/2 tapped.

eX m encaspulated solenoid Valves

features

- The 5/2 and 5/3 spool solenoid valves have threaded port connections

- In order to provide better environmental protection against the ingress of liquids, dusts and other foreign matter, all of the exhaust ports are connectable. This is particularly recommended for sensitive areas, such as clean rooms, and applications within the pharmaceutical and food processing sectors

- The Ex m encapsulated solenoid valves can be externally piloted via an external air pilot supply, in order to convert the valve to zero minimum operation by flipping a gasket

- The solenoid valves can be mounted in any position without affecting operation

- Threaded pipe connection identifier is 8 = NPT (ANSI 1.20.3); G = G (ISO 228/1)

asco 551-553 solenoid valves

specification

Differential Pressure: 2 – 10,4 bar [1 bar =100 kPa]

Flow (Qv at 6 bar): 1/4 = 860 l/min (5/2) ; 760l/min (5/3) (ANR) | 1/2 = 3800 l/min (5/2, 5/3)

Fluids: air, inert gas, filtered

Temperature Range: -25°C to +60°C

Seal Materials: NBR (nitrile) + PUR (polyurethane)

Materials In Contact With Fluid

| Body | Aluminium, black anodised |

| End cover (spring return) | Glass-filled PA |

| Spool valve internal parts | Zamak, stainless steel, POM, aluminium |

| Pilot end covers | Aluminium |

| Core tube | Stainless steel |

| Core and plugnut | Stainless steel |

| Core spring | Stainless steel |

| Seals | NBR (Nitrile Butadiene Rubber) |

| Top disc | PA (Polyamide Nylon) |

| Disc holder | POM (Polyoxymethylene) |

| Cartridge (low power) |

Welded, stainless steel or aluminium |

| Seat |

Brass |

| Seat insert |

POM (Polyoxymethylene) |

| Shading coil |

Copper |

| Rider rings (low power) |

PTFE (NF/WSNF solenoids only) |

➡ The complete specification for the full range of ASCO 551-553 encapsulated solenoid valves is available in the Data Sheet.

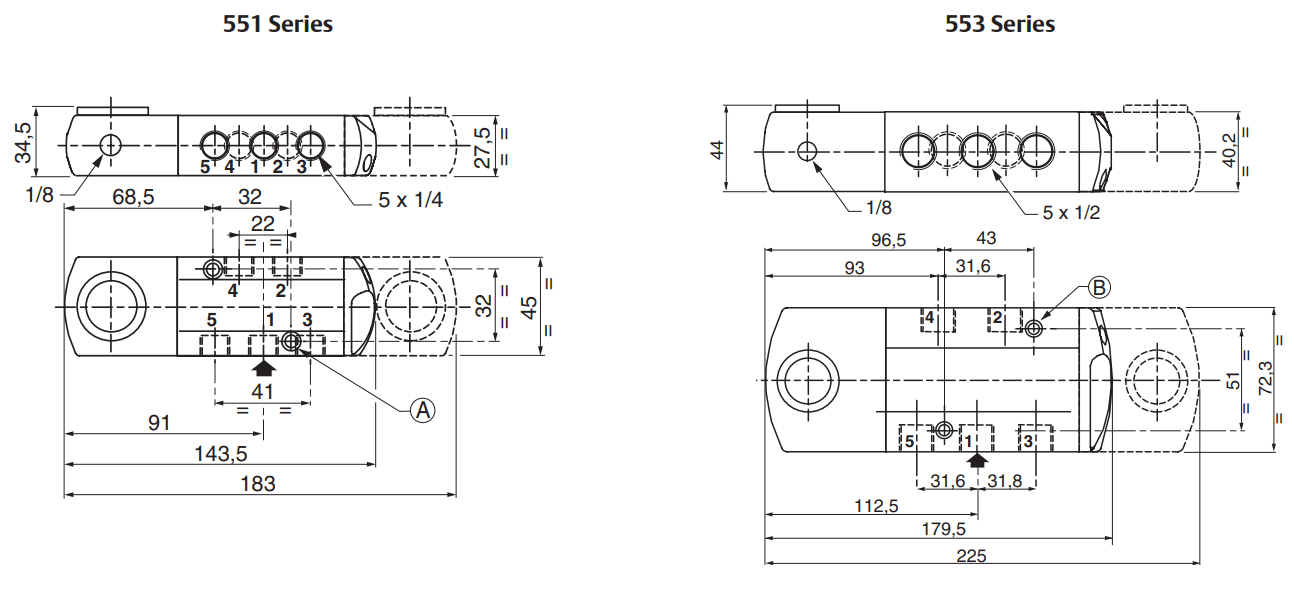

asco 551-553 valves – dimensions

Type ASCO 551 – 553

- A (551 Series) – 2 mounting holes: 5,3 mm dia.; Spotfacing: 9 mm dia., depth 5 mm

- B (553 Series) – 2 mounting holes: 6,5 mm dia.; Spotfacing: 11 mm dia., depth 6 mm

ASCO 551-553 Aluminium Valves | Ex m Encapsulated ATEX IECEx Solenoid Valves 5/2 5/3 (PV)

SOLENOIDS

Ordering Information: A solenoid valve with the explosion proof operator will be identified with the prefix ASCO PV before the catalogue number.

For example

ASCO PV E 210D095 230V/50Hz

Where:

- PV Solenoid Operator

- E Pipe Thread

- 210D095 Solenoid Valve | Operator Catalogue Number

- 230V Voltage

A valve supplied with the explosion proof operator will be identified with electrical interface A7 in the 15-digit product code.

For example

ASCO E 262 K 232 A7 V00 H1

Where:

- E Thread Connection

- 262 ASCO Solenoid Valve Series

- K Revision Letter

- 232 ASCO Solenoid Valves Version

- A7 Electrical Interface

- V00 Valves | Operators Options

- H1 Voltage Class

Explanation of Temperature Ranges of Solenoid Valves

- Valve Temperature Range – the valve temperature range (TS) is determined by the selected seal material, the temperature range for proper operation of the solenoid valve and sometimes by the fluid (e.g. steam).

- Valve Operator Ambient Temperature Range – the operator ambient temperature range is determined by the selected power level and the safety code.

- Total Temperature Range – the temperature range of the complete solenoid valve is determined by the limitations of both temperature ranges above.

Electrical Connections for Solenoid Valves

The following information displays the electrical connection options available for this range of explosion proof solenoid valves manufactured by ASCO:

| Prefix | Connection |

| SC | Spade plug connector with cable gland EN175301-803A (ISO 4400) for cables with an outer diameter from 6 to 10 mm |

| WP, WS, EM, WSEM | M20 plastics cable gland for cables with an outer diameter from 7 to 12 mm |

| NF, WSNF, LPKF, WSLPKF | 1/2″ NPT threaded cable entry. Enclosures are supplied without cable gland |

| PV | Moulded-in cable, standard length 2 m |

| LI, WSLI | 1/2″ NPT threaded cable entry. Enclosures are supplied without cable gland |

| EF | 1/2″ NPT conduits, standard length 35 cm |

- Valves configured for external pilot air supply, TPL 20547

- Other pipe threads are available on request

- Ex mb/mD (prefix “PV”) solenoid can be supplied with various cable lengths

- Compliance with “UL”, “CSA” and other local approvals available on request

Certified For Hazardous Area Flow Control | ATEX Valves

Flameproof | Encapsulated | Increased Safety | Intrinsically Safe | Non-Sparking Explosion Proof