Ex d Radiators | Flameproof Space Heaters for Hazardous Area Zone 1 & Zone 2 | Chromalox RHEX

Ex d Flameproof Radiators | Chromalox RHEX

Please note this product has been discontinued contact T&D for an alternative.

Ex d Radiators

Chromalox RHEX

Chromalox RHEX liquid filled Ex d radiators provide flameproof hazardous area certified heating for harsh, industrial applications within Zone 1, Zone 2, Zone 21 and Zone 22.

The Chromalox RHEX liquid filled radiator has a rugged, corrosion resistant, painted aluminium shell which can withstand wet, corrosive environments. Stainless steel heating elements are fitted with an integral safety thermostat and thermal fuse in order to prevent overheating. Liquid filled Ex d radiators are certified to meet ATEX equipment directive standards and have an ingress protection rating of IP66. The RHEX is supplied with a wall mounting bracket and a 2 metre (6.5 ft) power cable.

Hazardous Area Certification

ATEX certified Ex d radiators:

- Explosive Gas: II 2G Ex d IIC T4 Gb

- Explosive Dust: II 2D Ex tD IIIC T130°C Db

- Rated for ambient operating temperatures: -20°C to 40°C (14°F to 104°F)

- Ingress Protection Rating: IP66

Electrical Heaters | Thorne & Derrick distribute from stock the most extensive range of Explosion Proof Electrical Heating products for both Ex e Increased Safety & Ex d Flameproof concepts – this includes both flammable gas (Zone 1/2) and dust (Zone 21/22) atmospheres according to ATEX & IECEx classifications

FLAMEPROOF EX D

What Does Flameproof Mean?

Principle: Flameproof is a type of protection in which the parts which could ignite an explosive atmosphere are located inside an enclosure which is able to withstand the pressure of an explosion of the explosive mixture inside. It also prevents the transmission of the explosion to the explosive atmosphere surrounding the enclosure. Technically unavoidable gaps are so long and narrow that hot gases jetting out will have lost their power to cause ignition by the time they reach the outside of the enclosure, or, alternatively, if the gaps are only required for the manufacturing process they may be sealed with an adhesive.

Important design parameters:

- Mechanical strength in accordance with a defined safety factor to withstand internal explosion pressure.

- As an orientation value, it may be assumed that inside the sphere approx. 0.8 MPa (8 bar) can be generated and that this sphere used as an Ex d enclosure must be able to withstand a pressure of 1.2 MPa (12 bar).

- Any gap between two parts of the enclosure must be kept so narrow and long that hot gas flowing out will not be able to ignite any explosive atmosphere which may be present in the potentially explosive atmosphere.

- The parameters for the gaps preventing the transmission of the ignition, width/length, are different for the explosion subgroups IIA, IIB and IIC. The most stringent requirements with regard to the gap parameters apply to enclosures in explosion subgroup IIC.

➡ Ex d Motor Starters | Ex d Enclosures & Junction Boxes | Ex d Lighting | Ex d Plugs & Sockets | Ex d Control Panels

Chromalox rhex

ex d radiators – specification

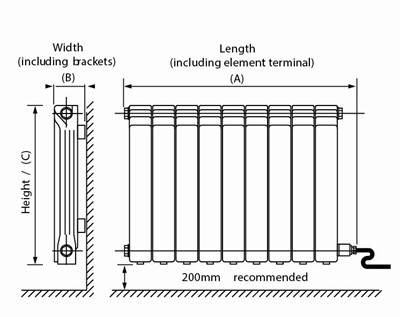

Chromalox RHEX Liquid Filled Radiators – Dimensions

Flameproof Ex d Radiators | Product Range

| Radiator Model | Power Output | Nominal Voltage | Length (mm) A |

Width (mm) B |

Height (mm) C |

Weight (kg) |

| RHEX 010 | 1000W | 230V / 1 ph | 550 | 118 | 880 | 19 |

| RHEX 020 | 2000W | 230V / 1 ph | 950 | 118 | 880 | 35 |

Contact Thorne & Derrick for excellent customer service, competitive quotations and delivery from stock for Chromalox heaters

Explosion Proof Exd Flameproof Heaters | Exd Radiators | Exe Increased Safety Heaters | Explosion Proof Convection Heaters | Exd Flameproof Heaters | Distributed by Thorne & Derrick | Experts in Equipment for Explosive Atmospheres

Experts in Equipment for Explosive Atmospheres

Learn more about our ATEX & IECEx Product Innovations and how we deliver significant improvements to clients plant, people and operational safety in the explosive atmosphere industries – we service UK and international projects with a comprehensive range of certified Electrical, HVAC and Process Instrumentation equipment for the hazardous area industries.

Hazardous Area ELECTRICAL, MECHANICAL & PROCESS INSTRUMENTATION Specialists

Thorne & Derrick International distribute Electrical, Mechanical, Process & Instrumentation Equipment to the global hazardous area industries and are approved vendors to most leading oil, gas and petrochemical companies and their EPC’s.

T&D supply ATEX & IECEx Certified equipment for the detection, metering, flow measurement and heat tracing of potentially explosive gases in hazardous areas Zone 1 and Zone 2 (Explosive Gas) and Zone 21 and Zone 22 (Explosive Dust).

Hazardous Area Equipment | Gas Detection | Metering | Lighting | Process Instrumentation | Plugs & Connectors | Trace Heating

Chromalox Product Range | Hazardous Area Heating | Immersion Heaters | Trace Heating Cables