September 2022 VISION!

Published 28 Oct 2022

Welcome to our industry bulletin – VISION.

So what is VISION?

VISION is our monthly round-up of industry news, projects, videos, technical tips, training information, webinars and career opportunities from Thorne & Derrick. Take a moment to Follow Us on LinkedIn to receive future VISION.

In The News

UK’s North Sea emissions down more than 20% since 2018

The UK’s North Sea oil and gas industry is on track to meet early emissions reduction targets after posting cuts of more than a fifth between 2018-21, according to new analysis. The latest Emissions Monitoring Report from the North Sea Transition Authority (NSTA) shows that greenhouse gas emissions were cut by an estimated 14.6% to 14.3 million tonnes of CO2e last year, adding up to an overall reduction of 21.5% since 2018.

According to The NSTA:

-

The UK needs secure and stable energy supplies, produced as cleanly as possible

-

Industry makes encouraging progress on emissions reductions

-

NSTA committed to holding sector to account on targets

-

Platform electrification vital to surpassing goals

Emissions are a by-product of extracting oil and gas, but industry is working hard to reduce them by investing in more energy-efficient equipment and technologies which minimise flaring.

This action, backed by the NSTA’s robust regulation, a reduction in offshore activity amid the Covid-19 pandemic and the permanent shutdown of several platforms with high emissions contributed to the decreases recorded in recent years.

The large number of platform maintenance shutdowns, timed to coincide with temporary pipeline closures, contributed to a substantial fall in production and associated emissions last year.

Encouragingly, NSTA projections indicate the sector is on track to meet interim emissions reduction targets – of 10% by 2025 and 25% by 2027 – which were agreed in the North Sea Transition Deal (NSTD) between the sector and UK government in 2021.

However, bold measures will be needed to hit the 2030 goal of halving emissions. Upgrading platforms to run on clean electricity, instead of gas or diesel, is essential – the NSTD will not be delivered without it, the NSTA said. At least two electrification projects should be commissioned by 2027, the authority added.

The NSTA will continue driving further reductions by robustly managing performance, including through the annual stewardship survey, monitoring and benchmarking, tier reviews and publishing new and updated guidance.

INDUSTRY EVENTs

Tank Storage 2022

Thorne & Derrick exhibited at Tank Storage 2022 for the first time this month! The event was well attended and we really enjoyed meeting with clients to discuss future projects.

T&D’s Terry McDonald & Laura McCabe showcased a variety of products and solutions to enable the smooth operation of bulk liquid storage; including a range of specialised equipment such as lighting, power, heat, ventilation & portable gas detection – providing protection for workers in a range of different applications.

Thorne & Derrick are now servicing further portable requirements, including the supply of heat light and ventilation products.

Special thanks to Andy and Miles from Wolf for meeting with us for dinner and celebrating another successful year of partnership.

Terry returned happy as his favourite drink was available on tap at the hotel; although he was stuck with the worst room again!

➡ See our full range | Heat | Power | Light | Ventilation | Gas Detection

A VIEW FROM SITE

INSTALLING WITH A VIEW!

Another series of beautiful photos from Peter Horne, National Field Manager at Hydro-Logic Services, of a VEGA installation with a fantastic view. We look forward to seeing more pictures with a view like this!

VEGAPULS radar level sensors manufactured by VEGA, providing non-contact level measurement of liquids and bulk solids.

PROJECTS & NEWS

WHY GAS DETECTION IS CRUCIAL IN ANAEROBIC DIGESTION

Thorne & Derrick are thrilled to release a NEW WHITEPAPER developed in partnership with Crowcon.

➡ Read The Full Whitepaper Here | Anaerobic Digestion

Anaerobic digestion consists of a series of processes that use microorganisms to decompose organic or biodegradable waste. It is applied intentionally as a method of waste disposal, sewage treatment and to produce biogas fuels.

The process of anaerobic digestion is growing in popularity as it is viewed as an environmentally friendly way to deal with waste and also produces an organic fuel source.

As you would expect with the production of biogas, there are a number of dangers associated with anaerobic digestion that need to be addressed. The application of robust safety measures and risk mitigation are necessary for any business or organisation involved in anaerobic digestion.

Written by Crowcon in conjunction with Thorne & Derrick, this whitepaper, takes a closer look at the hazards that arise during anaerobic digestion, including those posed by dangerous gases, and how the risks can be carefully controlled and reduced.

ILLUMINATING YOUR WORKSPACES

Thorne & Derrick have been assisting an electrical distribution company with compliant lighting for their application. The project involved the outfitting of a freezer which was set to reach up to -35°C . Due to the hazardous classification of this particular area, Zone 2 compliant hazardous area lighting was required.

We specified and supplied a Zone 2 Raytec Spartan Hazardous Area Light Fitting for the project, which is now being trialled with the client before they proceed with further Raytec fittings.

T&D were also approached for a large quantity of both emergency and standard light fittings to illuminate a large ammonia plant during the darker nights. Performing our lighting design service in partnership with Raytec, we identified the required light fittings to deliver the most efficient solution.

An Ammonia Plant

Does your plant have a lighting requirement this Winter? Using the latest software, Thorne & Derrick can provide a FREE LIGHTING DESIGN SERVICE for the specification and supply of ATEX & IECEx Certified light fittings to provide safe and reliable lighting in explosive atmospheres and hazardous area locations.

Prevent Your Drum & IBC Containers From Freezing This Winter

With winter now fast approaching, Thorne & Derrick have been assiting with heating requirements to prevent the contents of drums and IBCs freezing during the colder months. We supply a wide range of electrical heating jackets from stock to heat up drums and IBC containers from 25L-1000L, with bespoke options for non-standard containers.

Electrical Heating Jackets Customised for Hazardous Area Vessel Heating

Our heating jacket technology can be adapted to suit non-standard containers and bespoke applications – suitable for both harsh industrial and hazardous areas.

Thorne & Derrick can also supply Radar Level Sensors to deliver highly accurate non-contact measurement of liquids stored in containers.

We recently delivered a measurement solution to a client who was using IBC’s filled with a methanol mix, and therefore required a product suitable for use in hazardous areas. T&D specified the VEGAPULS 21 radar level sensor manufactured by VEGA which is ex approved and is certified to the current ATEX & IEC standards.

VEGA radar level sensors deliver non-intrusive measurement, which refers to the use of devices or measurement procedures that induce minimal impact on the person involved. The VEGAPULS 21 is also maintenance-free due to non-contact 80 GHz radar technology, which is able to give exact measurement results independent of medium properties and process conditions.

LEt’s Celebrate!

Hazloc Heaters are pleased to announce that they are celebrating their 18th Birthday!

“We would like to thank all our Employees, Representatives, Distributors and Suppliers for their hard work and dedication to bring Hazloc Heaters to the forefront as a leading manufacturer of Industrial Heating equipment.

Also thank you to our customers for your ongoing commitment and loyalty. We are happy to serve you.”

Terminology Explained

Every industry has its own language, terms and acronyms. Below is a selection of the common terms in use in the Explosion industry today and how they are employed in current directives.

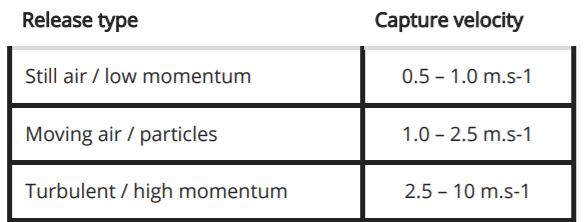

This month we focus on Dust Extraction and the risks involved.

Dust extraction is important to limit fugitive emissions and it should be routinely monitored to ensure satisfactory performance. In addition, the level of ventilation should ensure that the dust-air concentration does not routinely exceed 25 % of the lower explosive limit LEL or minimum explosible concentration MEC). The ‘capture velocity’ is also important and this depends on the level of air movement in the region of interest.

Dusts, which are not removed by mechanical extraction ventilation, settle out, at a rate depending on properties such as particle size, into layers or accumulations and account has to be taken of the fact that dilute or small continuous sources of release (in time) may produce a potentially hazardous dust layer.

Principally, three risks are presented by dust layers:

Risk 1: A primary explosion within a building may raise dust layers into clouds, and cause secondary explosions more damaging than the primary event. Dust layers should always be controlled to reduce this risk.

Risk 2: Dust layers may be ignited by the heat flux from equipment on which the layer rests. The risk is of fire, rather than explosion, and this may be a slow process.

Risk 3: A dust layer may be raised into a cloud, ignite on a hot surface and cause an explosion. In practice, dust cloud ignition temperatures are often much higher than layer ignition temperatures. For example, Paper fines have a layer ignition temperature of 210 – 275 °C, but a cloud ignition temperature of > 450°C.

These risks depend on the properties of the dust and the thickness of layers, which is influenced by the nature of the housekeeping. The likelihood of a layer catching re should be controlled by the correct selection of equipment and effective housekeeping.

VISION! BY,

EXPERTS IN EQUIPMENT FOR EXPLOSIVE ATMOSPHERES

LEADERS IN ATEX INNOVATION TO THE HAZARDOUS AREA INDUSTRIES

Thorne & Derrick are leaders in the development and distribution of Product Innovations that deliver significant improvements to clients plant, people and operational safety in the explosive atmosphere industries.

Your proactive problem solvers experienced in succession planning for the replacement of obsolete, non-conformant and legacy equipment in hazardous areas.

Your first-choice provider of innovative and competitive solutions to ensure ATEX & IECEx Compliance for Hazardous Area Electrical, HVAC & Process Instrumentation Equipment to UK and international projects.

Control Panels | Plugs | Isolators | Enclosures & Junction Boxes | Lighting | Control Stations | Motor Starters | Heat Trace | Gas Detection | Flame Detection | Process Instrumentation | Process Heating | Ventilation Fans | Security Access Control