Trace Heating EL-Rail | Network Rail Solution

Published 20 Oct 2023

Trace Heating | EL-Rail

Network Rail

Ensuring safe railway traffic is crucial, especially during winter months. Railway tracks and switch points must be free from ice and snow to avoid any potential hazards. That’s why Network Rail, the British Operator, tested electrical heat tracing on 29 km of track in Kent and Sussex.

The EL-Rail system by Eltherm was installed on entry and departure tracks at all railway stations, delivering reliable results. Due to its success, the test project was extended to include 106 km of heated tracks throughout the country. Passenger safety is a top priority, and this innovative solution ensures a safe and efficient railway system for all.

The EL-Rail system uses electrical heat tracing cables embedded into the rail track which are activated when temperatures drop below a certain threshold. The cables are powered by a control panel that enables remote monitoring and adjustments to ensure optimal performance.

The system proved to be more efficient and cost-effective than traditional snow clearing methods such as ploughing and gritting. It also reduced the risk of track damage from snowploughs and decreased the time needed for maintenance. Additionally, it provided more reliable and punctual train services during winter months, improving overall passenger experience.

Thorne & Derrick, the UK’s leading Specialist Distributor of Electrical Process & Trace Heating Solutions, earlier this year announced they have entered into a Strategic Partnership with Eltherm UK Ltd, the subsidiary of the Eltherm Group, a world-class manufacturer of Heat Tracing Cables & Systems for the commercial, industrial and hazardous area industries.

Eltherm Rail Trace Heating FAQs

What is the difference between EL-Rail, EL-Point and El-Track?

In summary, EL-Point is specifically designed for switch points, EL-Track is a fixed wattage solution for rail networks of varying lengths, and El-Rail is best suited for long distances and heating circuits up to 300 meters. The differences in their designs cater to the specific needs of different types of railway systems.

What do Eltherm engineers need to know to achieve an optimised design?

The engineers need to know the following parameters: radius and length of switch point or rail to be heated, the rail geometry, operating voltage and the required power output.

What can influence the design?

Various rail geometries and specifications for switch points involve a range of devices attached to the rail that may require special attention. The design engineer will check how to overcome these obstacles on the outside of the stock rail.

How do Eltherm solutions differ with different track geometries?

Custom designed solutions are often required to adapt the cover profile to the shape and design of the rail, combined with the holding bracket. The trace heating solution itself does

not vary.

When should you us Switch Point Lock heating?

Heating the switch point lock should be used wherever the quantity of snow and ice may interfere with the mechanical setting of the switch point. This is a valuable safety feature.

What benefits does a Switch Point Lock heating offer?

Heating the switch point lock with a power output of 500 – 900 W activates heat transfer to the switching mechanism through reflection from the black surface on the inside. The heat is thus distributed evenly. At the same time, the surface temperature of the switch point lock is limited to 60 °C. This avoids debris and leaves catching fire.

Which accessories are needed?

The heating system includes a cover profile and suitable holding brackets and may be extended to include junction boxes, protective hoses or complete power and control systems.

Which applications are not suitable for EL-Rail, EL-Point or EL-Track?

This may be the case when the heating system cannot be installed on the outside of the stock rail because of devices or obstacles that disrupt heat transfer for a long stretch.

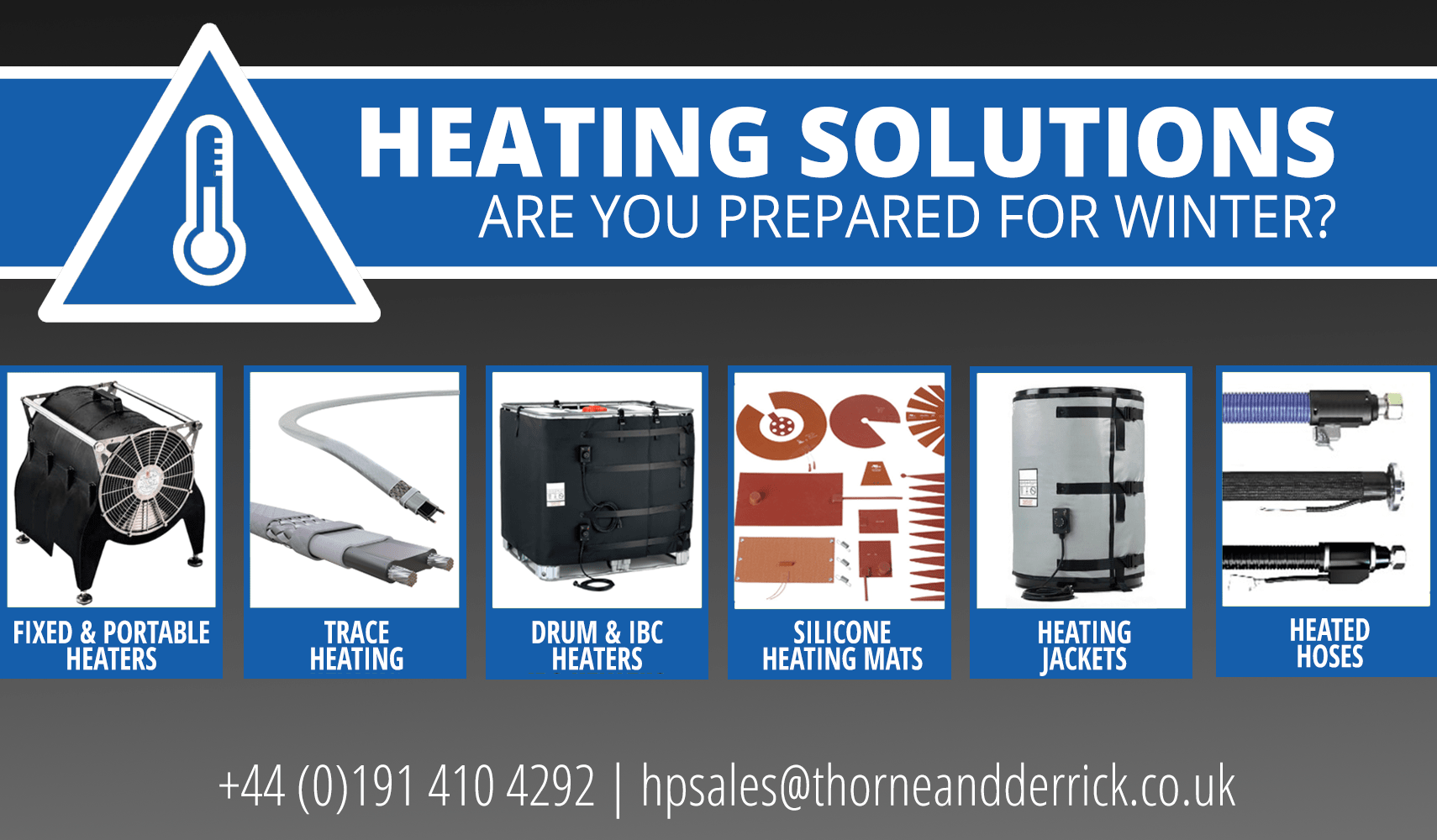

The Electrical Heating Package

Thorne & Derrick provide a complete portfolio of Electric Process & Trace Heating Solutions for Industrial, Hazardous Area & Explosive Atmospheres,

- Trace Heating Systems & Cables

- Serial Resistance Trace Heaters

- Parallel Resistance Trace Heaters

- Self-Regulating Parallel Trace Heaters

- Mineral-Insulated Trace Heaters

- Commercial |Ramp Heating & Gutter Heating

- Industrial | Explosive Proof ATEX & IECEx Certified for Hazardous Areas

- Zone 1 & 2 (Flammable Gas) or Zone 21 & 22 (Combustible Dust) | Class I, Division 1 & 2

- Process Heating

- Air, Immersion & Line Heaters

- Heated Hoses – Analytic & Pressure

- Heating Mats & Jackets

- Drum, IBC & Container Heaters

Specialist Distributors of Electrical Heating, Lighting, Power & Process Instrumentation Equipment to deliver significant safety and reliability improvements in the Industrial, Explosive Atmosphere & Energy sectors.

Your proactive problem solvers experienced in succession planning for the replacement of obsolete, non-conformant and legacy equipment in hazardous areas with ATEX & IECEx Certification & DSEAR Regulatory Compliance.

Industries Supplied | Process, Oil & Gas, Petrochemical, Utility (Water, Gas & Electricity), Food & Beverage, Pharmaceutical, Renewable, Rail, Datacentre, Battery Storage

Product Categories | Electric Heating | Lighting | Control Panels | Confined Space Safety | Plugs & Sockets | Isolators | Enclosures & Junction Boxes | Control Stations | Motor Starters Gas Detection | Security Access Control | Duct Seals | Cable Accessories LV HV | Earthing & Lightning Protection | Feeder Pillars | High Voltage Electrical Equipment | Joints Terminations Connectors MV HV