Constant Wattage Heat Tracing Cable | Eltherm ELP/Si-F 20 BOT Heat Tracing Cable up to 200°C

Constant Wattage heat tracing Cables

Industrial Heat Tracing Cable | Eltherm ELP/Si-F-20-BOT

Eltherm ELP/Si-F constant wattage heat tracing cables provide process temperature maintenance and frost protection to pipework, instrument lines, tanks and drums up to 200° Celsius.

These heat tracing cables manufactured by Eltherm offer flexibility in use as they can easily be cut to the required length off the roll, with the assurance of constant power output. There is no need for connecting cable and input can be unilateral. The constant wattage heat tracing cable is quick and easy to assemble, saving time and reducing operating costs.

Since the trace heater cable output of up to 40 W/m is possible for lengths laid to piping, Eltherm ELP/Si-F heat tracing cables are particularly suited for piping with high output requirements such as in industrial process technology. The following are applications are below:

- Chemistry & Petrochemistry

- Building Construction

- Food Processing Industry

- Paper Industry

- Process Industries

Heat tracing cables

SPECIFICATION

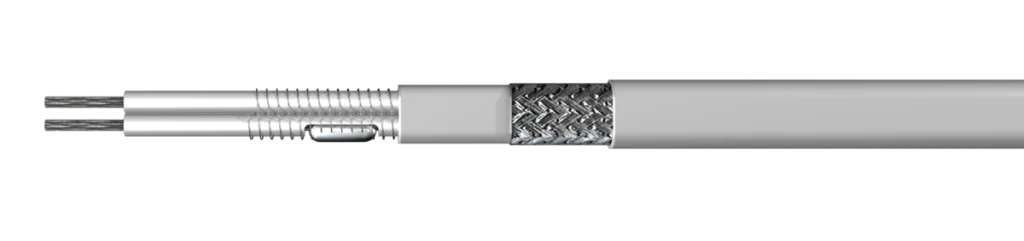

Eltherm ELP/Si-F-20-BOT Process Heat Tracing Cable wattages per metre – 20, 30 and 40 watts.

- Nominal Supply Voltage : 230v AC/DC or 400V AC/C

- Permissible Ambient Temperature : -70 to +200ºC

- Minimum Installation & Start-Up Temperature : -70° Celsius

- Minimum Heater Cable Bend Radius : 30 mm

- Cables Outer Jacket: Fluoropolymer

- Cables Protective Braid: Copper/Zinc

- Insulation: Silicone

- Cable Dimensions: 7 mm x 10.5 mm

- Bus Wire Cross Section: 2 mm²

- Eltherm Process Heating Cables Order Code: 0320220

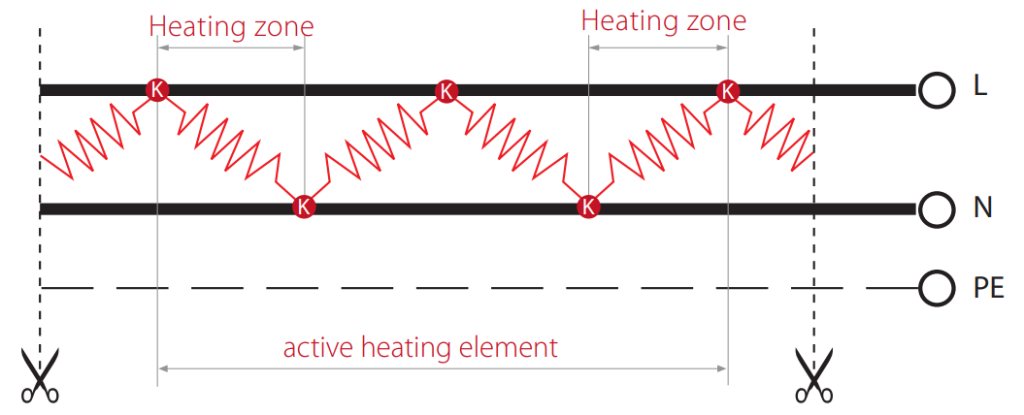

- Bus wire: Copper

- 1st insulation: Silicone

- Heating conductor: Heating conductor alloy

- 2nd insulation: Silicone

- Protective braid: Copper, nickel-plated

- Outer jacket: Fluoropolymer (BOT)

ELTHERM ELP/SI-F 20 BOT HEATING CABLE BENEFITS

- Single end power input

- Trace heating cable can be cut from the cable drum

- Constant power output per meter

- Long life cycle

- Laying without exact measuring possible

- High chemical resistance

- UV resistance heating cables

- Moisture proof

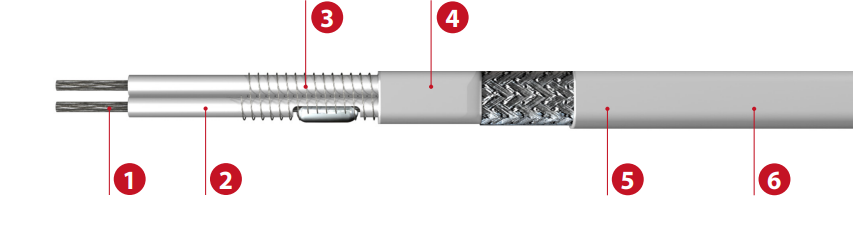

Constant wattage heating cables such as the ELP/Si consist of a succession of heating zones (length = contact spacing) and can be cut to length in sections of the contact distance to the required length – when cutting heater cables into lengths, the heating circuit is interrupted up to the next contact point and this non-active part can be used as a cold lead.

Heat tracing cable selection table – eltherm elp/si-f-20-BOT

Contact T&D for technical guidance, heat loss calculations for pipework systems and optimum specification of the correct trace heater cable for your application.

| Type | Nominal Output (W/m) | Contact Spacing (m) | Length (m) at 10 °C | Length (m) at 100 °C | Maximum maintenance temperature °C | Nominal Voltage (V) |

| ELP/Si F 20 BOT | 20 | 0.7 | 147 | 141 | 150 | 230 |

CONSTANT WATTAGE HEATING CABLES

Constant wattage heating cables consist of a succession of heating zones (length = contact spacing) and can be cut to length in sections of the contact distance to the required length – when cutting heater cables into lengths, the heating circuit is interrupted up to the next contact point and this non-active part can be used as a cold lead.

Constant wattage heater cable when installed onto pipework for frost protection or process temperature maintenance must not intersect, contact or overlap to prevent overheating.

Self-regulating heating cables can be overlapped without risk of burn-out or overheating.

Bespoke Heated Hose Designs | 40+ Years Experience from Process Heating Specialists | CONTACT US