ASCO EM/WSEM | Ex e mb Increased Safety Encapsulated ATEX IECEx Solenoid Valve Operators

ASCO EM WSEM | Ex e mb Increased Safety Encapsulated ATEX IECEx Solenoid Valve Operators

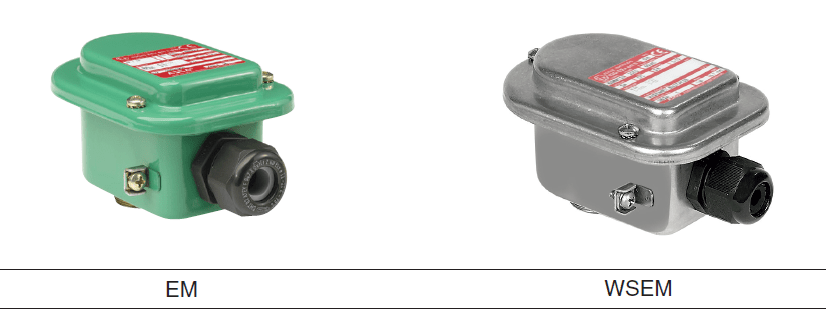

ASCO EM/WSEM Solenoid Operators

EX E MB INCREASED SAFETY & ENCAPSULATED

ASCO EM/WSEM explosion proof solenoid valve operators are ATEX certified for installation in potentially explosive atmospheres located in hazardous areas.

The solenoid operators with Increased Safety and Encapsulation IEC explosion protection techniques. They are suitable for use in hazardous areas with exposure to gas, classified as Zone 1.

Hazardous Area Classification & Ex Safety Code

ATEX Solenoid Valves

II 2G Ex e mb IIC T6..T3 Gb

II 2D Ex tb IIIC 85°C..200°C Db IP66/67

EC type certificate KEMA 98ATEX2542 X and IECEx certificate (IECEx KEM 08.0002X). IP66/67 ingress protection.

The Ex e mb solenoid operators used in conjunction with valves are compliant with International and European Standards EN-IEC 60079-0, EN-IEC 60079-7, EN-IEC 60079-18 and EN-IEC 60079-31 and also certified for use in potentially explosive atmospheres according to ATEX-Directive 2014/34/EU.

ASco EM/WSEM operators – features

- Ingress Protection Rating: IP66/67

- The solenoid operators have a zinc-plated steel (EM) or stainless steel (WSEM) enclosure which features integral strain relief for cable with an O.D. of 7 to 12 mm

- ASCO EM/WSEM are easily installed with a screw terminal coil

- Peak voltage suppression is standard for DC executions

- A range of solenoid valves can be supplied with the Ex e mb operator

asco wBLp operators – CONSTRUCTION

| Solenoid enclosure | EM – Zinc plated steel (epoxy coated) WSEM – stainless steel, AISI 316 |

| Cable gland | PA, M20 x 1.5 |

| Core, core tube and plugnut | Stainless steel |

| Shading coil | Copper or silver |

| Nameplate |

Polyester |

| Coil connection | Embedded screw terminals |

| Safety code | II 2G Ex e mb IIC T6..T3 Gb II 2D Ex tb IIIC 85°C..200°C Db IP66/67 |

ELECTRICAL CHARACTERISTICS & Connections

Standard voltages:

- DC (=) : 24V – 48V

- AC (~) : 24V-48V-115V-230V / 50 Hz 24V-48V-100V-115V-200V-230V / 50-60 Hz

- Features an internal and an external earthing connection

- The ASCO EM/WSEM operator can be rotated through 360° to select the best position for cable entry

TEMPERATURE CLASSIFICATION

asco em/wsem

AC (~) Solenoids

| Pn (watt) | Solenoid Size | Maximum Ambient Temperature °C | |||||

| M6 | MXX | M12 | Surface Temperature | ||||

| T6 85°C |

T5 100°C |

T4 135°C |

T3 200°C |

||||

| Insulation Class F (155°C) 100% E.D. | |||||||

| 1.2* | ◊ | 60 | 75 | ||||

| 1.5* | ◊ | 40 | 55 | ||||

| 1.85* | ◊ | 40 | 55 | ||||

| 3.7* | ◊ | 40 | 55 | 75 | |||

| 5.8* | ◊ | 40 | 75 | – | |||

| 6.0 | ◊ | 40 | |||||

| 9.0 | ◊ | 40 | |||||

| 10.0* | ◊ | 40 | |||||

| 10.0* | ◊ | 40 | 65 | ||||

| 10.5 | ◊ | 40 | |||||

| 13.0 | ◊ | 40 | |||||

| 13.6* | ◊ | 40 | |||||

| 14.1* | ◊ | 40 | |||||

| 16.5 | ◊ | 40 | |||||

* AC (~): rectified coil construction

DC (=) Solenoids

| Pn (watt) | Solenoid Size | Maximum Ambient Temperature °C | |||||

| M6 | MXX | M12 | Surface Temperature | ||||

| T6 85°C |

T5 100°C |

T4 135°C |

T3 200°C |

||||

| Insulation Class F (155°C) 100% E.D. | |||||||

| 1.3 | ◊ | 60 | 75 | ||||

| 1.7 | ◊ | 40 | 55 | ||||

| 1.8 | ◊ | 40 | 55 | ||||

| 3.6 | ◊ | 40 | 55 | 75 | |||

| 5.7 | ◊ | 40 | 75 | – | |||

| 9.7 | ◊ | 40 | |||||

| 10.0 | ◊ | 40 | 65 | ||||

| 11.2 | ◊ | 40 | |||||

| 14.0 | ◊ | 40 | |||||

| 15.3 | ◊ | 40 | |||||

| 16.8 | ◊ | 40 | |||||

| 19.7 | ◊ | 40 | |||||

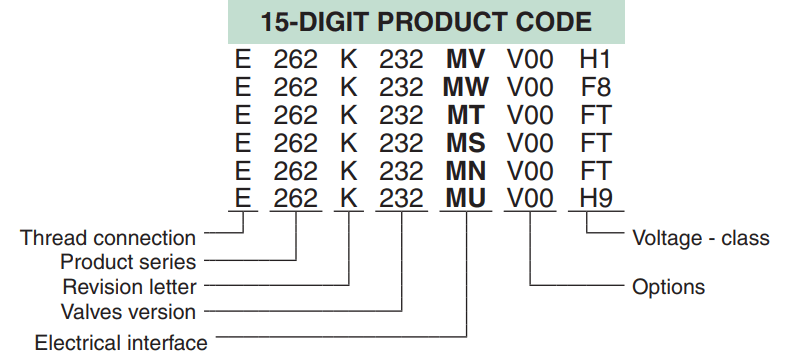

ex e mb sOLENOID operator ORDERING INFORMATION

ex e mb sOLENOID operator ORDERING INFORMATION

The valve supplied with the explosion proof operator will be identified with prefix EM/WSEM before the catalogue number. For example:

*Electrical interface

MV = EM

MW = WSEM

MT = EMET

MS = WSEMT

MN = EMT

MU = WSEMET

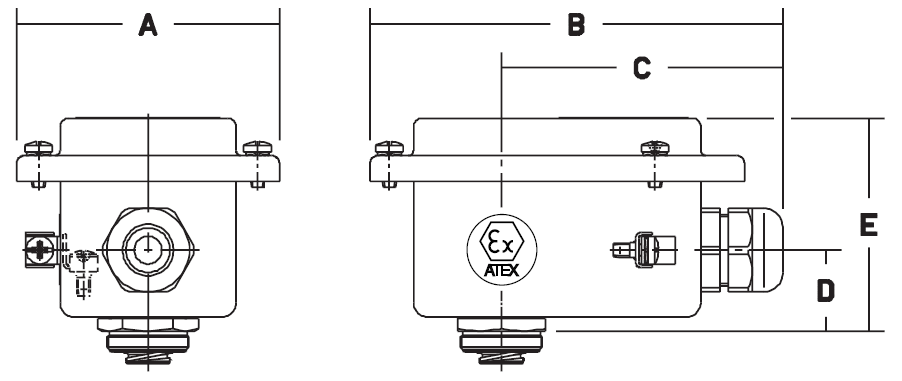

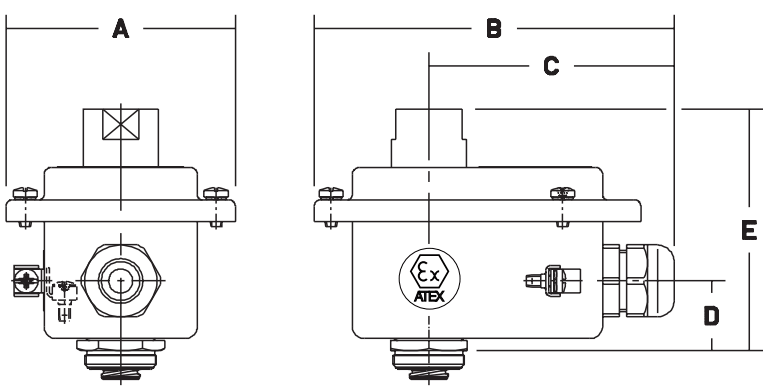

dimensions

TYPE EM/WSEM

Prefix “EM”/”WSEM” solenoids / Electrical interface MV/MW/MT/MS/MN/MU

Pull-type solenoid operator

Metal enclosure, epoxy coated or stainless steel

EN-IEC 60079-7, EN-IEC 60079-18 and EN-IEC 60079-31

II 2G Ex eb mb IIC Gb, II 2D Ex tb IIIC Db IP66/67

| Solenoid Valve Series/Size | A | B | C | D | E | Weight |

| EM/WSEM-M6 | 77 mm | 120 mm | 82 mm | 26 mm | 64 mm | 0.48 kg |

| EM/WSEM-MXX | 77 mm | 120 mm | 82 mm | 23 mm | 62 mm | 0.55 kg |

| EM/WSEM-M12 | 77 mm | 120 mm | 82 mm | 21 mm | 65 mm | 0.67 kg |

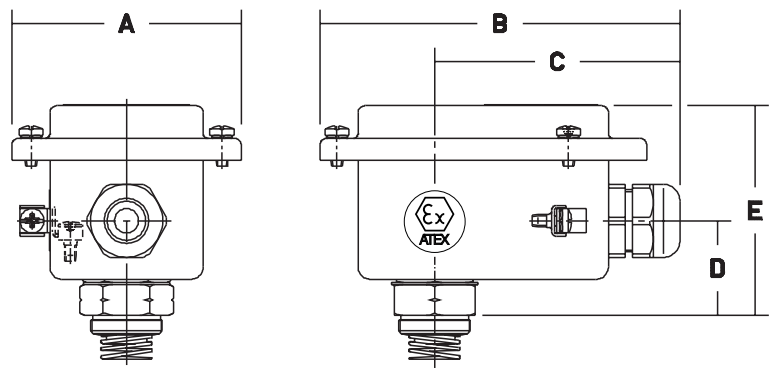

TYPE EM/WSEM

Prefix “EM”/”WSEM” solenoids / Electrical interface MV/MW/MT/MS/MN/MU

Push-type solenoid operator

Metal enclosure, epoxy coated or stainless steel

EN-IEC 60079-7, EN-IEC 60079-18 and EN-IEC 60079-31

II 2G Ex eb mb IIC Gb, II 2D Ex tb IIIC Db IP66/67

| Solenoid Valve Series/Size | A | B | C | D | E | Weight |

| EM/WSEM-M6 | 77 mm | 120 mm | 82 mm | 25 mm | 63 mm | 0.50 kg |

| EM/WSEM-MXX | 77 mm | 120 mm | 82 mm | 31 mm | 69 mm | 0.59 kg |

| EM/WSEM-M12 | 77 mm | 120 mm | 82 mm | 30 mm | 73 mm | 0.70 kg |

TYPE EM/WSEM

Prefix “EM”/”WSEM” solenoids / Electrical interface MV/MW/MT/MS/MN/MU

Pull-type solenoid operator

Metal enclosure, epoxy coated or stainless steel

EN-IEC 60079-7, EN-IEC 60079-18 and EN-IEC 60079-31

II 2G Ex eb mb IIC Gb, II 2D Ex tb IIIC Db IP66/67

| Solenoid Valve Series/Size | A | B | C | D | E | Weight |

| EM/WSEM-MXX | 77 mm | 120 mm | 82 mm | 23 mm | 80 mm | 0.68 kg |

Flameproof | Encapsulated | Increased Safety | Intrinsically Safe | Non-Sparking Explosion Proof