WHITEPAPER | The Language of Explosion Safety By Declan Barry

Published 11 Mar 2022

- Republished with the kind permission of Declan Barry, Managing Director of ATEX Explosion Hazards Ltd.

ATEX Explosion Hazards Limited has spent nearly 50 years improving the health & safety of workers at work, in explosive atmospheres, in various industries.

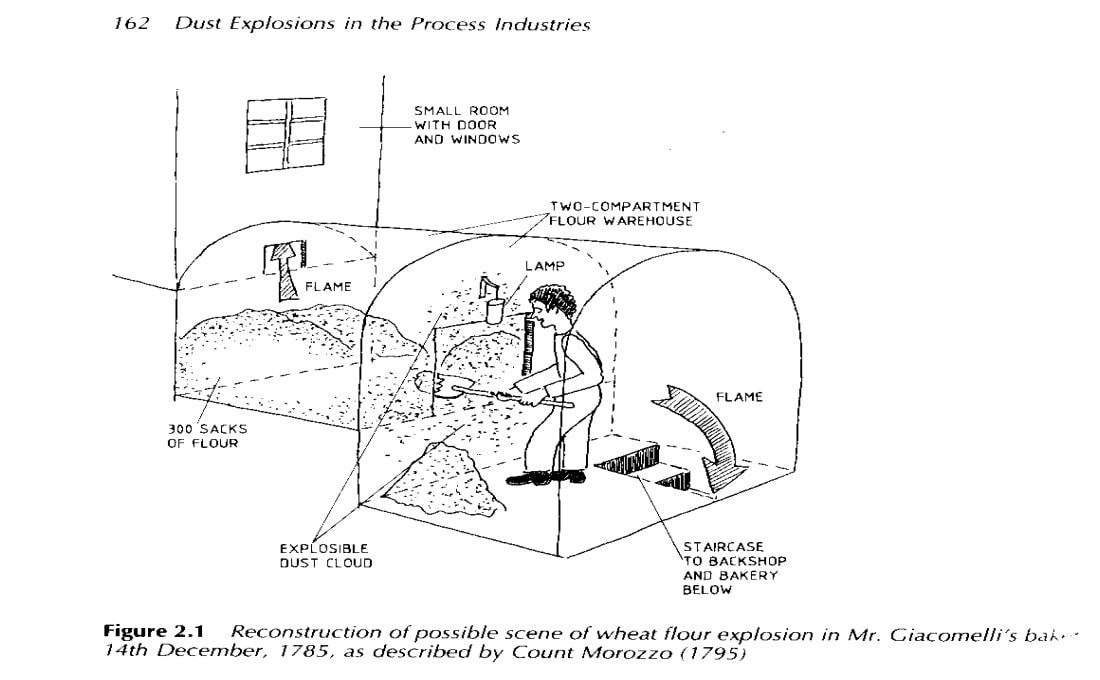

In their recent white paper, ATEX Explosion Hazards Limited explore the language of explosion safety. From the earliest recorded dust explosion in Mr Giacomelli’s bakery in the Piedmont area of Italy in 1785, through explosions in UK flour mills a century later, to the language used in legislation of the present day.

Every industry has its own language, terms and acronyms. Below is a Glossary of the common terms in use in the Explosion industry today and how they are employed in current directives. As well as a short overview of the main directives and legislative instruments that govern our industry as well as the testing and statistics that are used and how to interpret them.

Italy 1785

The earliest recorded Dust Explosion happened in Mr Giacomelli’s bakery in the Piedmont area in Italy on 14th December, 1785. A boy shovelling flour by naked candlelight from one level of a warehouse to another had his face and arms scorched in the blast, which blew out windows and released flames into the street.

Another boy, seeing the flames coming towards him, jumped off a scaffold and broke his leg. The accident was reported to be due to the dryness of the corn, as there had not been any rain for the last 5 to 6 months in the Piedmont area!

Figure 2.1 Dust Explosion in the Process Industries

UK Explosions in Flour Mills, 1888

A century later in the United Kingdom, a mill owner called Reynolds issued the following instructions to his staff; Within recent years, several disastrous explosions have occurred in flour mills, resulting in loss of life and destruction of much valuable property.

As all flour mills are liable to such explosions at any moment, it is desirable that the workmen should understand the chief causes of danger and how they may be best avoided. Explosions may be caused when any dust is mixed with air and a naked light brought into contact with the mixture. Flour sharps, stive wheat dust, smut-dust or sweepings will all explode either singly or when mixed.

It is therefore necessary of all who work in the mill that the following precautions shall be most carefully observed.

1. Never stir or mix up loose dust while gas is lit.

2. Never examine a machine with naked light.

3. NEVER ENTER ANY SIVE OR DUST ROOM WITH NAKED LIGHT

4. Never strike matches or smoke about the premises.

5. Where is necessary to sweep or dust at night, do it as quietly as possible

to avoid agitating the dust.

6. Always use closed lamps within the mill

7. Report a leakage of gas directly you find it.

We trust all our workmen will see the necessity for extreme care and the use of lights of all kinds. Should any man exhibit carelessness in this respect after this warning, we shall be obliged to dismiss him.

J Reynolds & Co.

October 1888

Irish Factories Act, 1955

“In the case of a process giving rise to dust of such a character and to such an extent as to be liable to explode on ignition, then, unless the plant is so constructed as to withstand the pressure likely to be produced by any such explosion, all practical steps shall be taken to restrict the spread of the effects of such an explosion by the provision, in connection with the plant, of chokes, baffles, and vents, or other effective appliances”.

EU July 2006

Organisations in the EU must follow the directives, to protect employees from explosion risk in areas with an explosive atmosphere.

This ATEX directive consists of two EU Directives:

1. ATEX 153 or (ATEX 137) Directive 99/92/EC – The responsibility of the User:

This Directive aims at establishing and harmonising minimum requirements for improving the safety and health of workers potentially at risk from explosive atmospheres.

2. 114 Directive 2014/34/EU – Harmonised requirements for the Manufacturer to sell to the User: The Directive of the European Parliament and the Council of Ministers on 26 February

2014 relating to Free trade of goods and the harmonisation of the laws of the Member States relating to equipment and protective systems intended for use in potentially explosive atmospheres.

UK Version

The UK version of the EU directives is known as the Dangerous Substances and Explosive Atmospheres Regulations (DSEAR). DSEAR requires employers to assess the risks of fires and explosions that may be caused by dangerous substances in the workplace & complements the requirement to manage risks under the Management of Health and Safety at Work Regulations.

DSEAR relates to assessments to how people may be affected by dangerous substances and explosive atmospheres. ATEX relates to assessments associated with the equipment that will be used in areas that may be affected by dangerous substances and explosive atmospheres.

CE is Conformity European but UKCA stands for UK Conformity Assessment. As of 1 January 2021, UKCA marking was to replace CE marking.

The United States

In the USA they have the National Fire Protection Association (NFPA), examples:

● NFPA 61: Standard for the Prevention of Fires and Dust Explosions in Agricultural and Food Processing Facilities

● NFPA 68: Standard on Explosion Protection by Deflagration Venting

● NFPA 69: Standard on Explosion Prevention Systems

● NFPA 85: Boiler and Combustion Systems Hazards Code

● NFPA 484: Standard for Combustible Metals

● NFPA 652: Standard on the Fundamentals of Combustible Dust

● NFPA 654: Standard for the Prevention of Fire and Dust Explosions from the Manufacturing, Processing, and Handling of Combustible Particulate Solids

● NFPA 655: Standard for Prevention of Sulfur Fires and Explosions

● NFPA 664: Standard for the Prevention of Fires and Explosions in Wood Processing and Woodworking Facilities

Glossary of Terms:

BZ Number: A product train of width 2 cm and length 4 cm is deposited on a ceramic plate and a glowing platinum wire inserted in an attempt to ignite the dust. After successful

ignition, the severity of the subsequent burning is observed.

| Test Result | Class | Reference | |

| No ignition | No spreading of fire | 1 | Table salt |

| Brief ignition, rapid extinction | 2 | Tartaric acid | |

| Localised combustion or glowing with practically no spreading | 3 | D + Lactose | |

| Glowing withou sparks (smoldering) or slow decomposition without flames | Fire spreads | 4 | H – acid, tabaco |

| Burning fireworks or slow quiet burning flames | 5 | Sulphur | |

| Very rapid combustion with flame propagation or rapid decomposition without flame | 6 | Black powder | |

Dust Hazard Analysis (DHA): Understand your hazardous materials, systematically evaluate processes risks, and manage by either administrative or engineering controls.

Explosion Proof: Explosion-proof or flame-proof equipment is sealed and rugged, such that it will not ignite a hazardous atmosphere, despite any sparks or explosion within.

Control Systems and Hazard and Operability (CHAZOP): Study more than HAZOP (qv.), control systems and individual failures of the processes.

Computational Fluid Dynamics (CFD): Software that simulates the dispersion of hazardous materials, fire and explosion.

Failure Mode & Effects Analysis (FMEA): Anticipate, identify and detect potential points of failure of design and consequence.

Fault Tree Analysis (FTA): FTA is a top-down, deductive failure analysis in which an undesired state of a system is analysed using Boolean logic, to combine a series of lower-level events.

Gap Analysis gives organisations an overview of the progress they have made in implementing each of the Standard’s controls.

Hazard Identification (HAZID): Risk analysis for early detection of hazards performed at the earliest stage of project development.

HAZLOC: In electrical and safety engineering, hazardous locations (HazLoc) are places where fire or explosion hazards may exist.

HAZOP: verify and test control and operations in your facility are robust and inherently safe, “as far as reasonably practicable.”

Intrinsic Safety: Intrinsic safety designs equipment to operate using minimal energy, insufficient to cause ignition.

Layers of Protection Analysis (LOPA): A method used to evaluate high-consequence scenarios determining if the combination of probability, of occurrence and severity of consequences, meets a company’s risk tolerance.

Occupational Safety and Health Administration (OSHA): A federal agency of the United States that regulates workplace safety and health.

Process Hazard Analysis (PHA): Potentially hazardous materials, to identify and evaluate dangers, control and mitigate by implementing safety measures.

Process Safety Management (PSM): interrelated approaches to managing hazards associated with the process industries and is intended to reduce the frequency and severity of incidents resulting from releases of chemicals and other energy sources.

Risk Assessment (RA): Risk assessments give organisations an indication of the threats facing them, how likely it is that each of those threats will occur and how severe the damage.

Statistics:

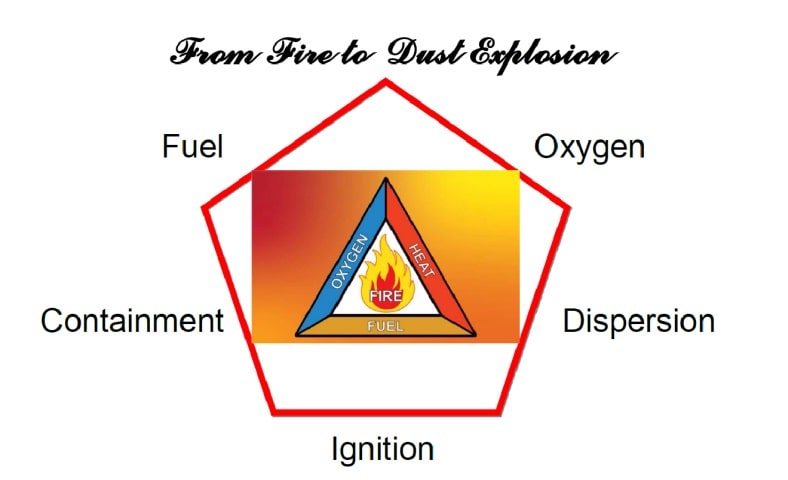

Going back to our basic science class, we have the Fire triangle but we need to add containment and dispersion for a dust explosion.

When presenting these articles we usually present Statistics:

| 2017 | 2018 | 2019 | 2020 | |

| Fires | 169 | 213 | 250 | 165 |

| Explosions | 68 | 68 | 74 | 60 |

| Injuries | 163 | 78 | 118 | 88 |

| Fatalities | 13 | 23 | 8 | 10 |

So there are more fires than explosions. In the EU we assume about 2 explosions per day in industry, but not all incidents are reported. What are we most interested in, when considering process safety:

Life Safety, Plant Safety and Mitigation

Material Properties:

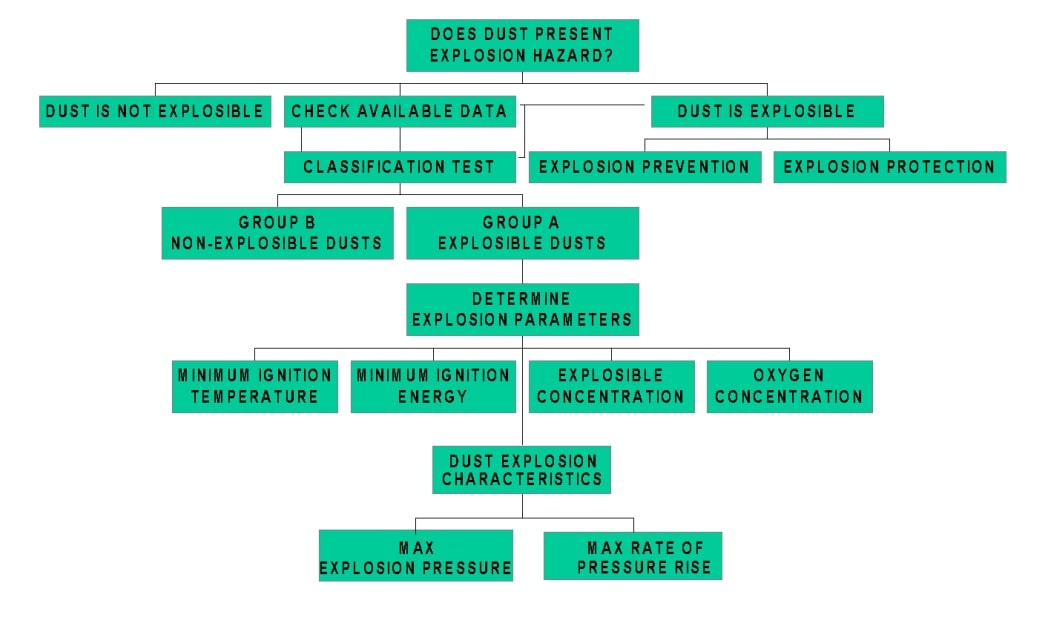

How do you know that a material is dangerous unless you test it?

Group A/B (Vertical Tube) Test: Essentially, the dust under test is dispersed in air at ambient temperatures, past a source of ignition and observations of fame propagation made by the

operative.

● Group A is a dust, which is able to ignite and propagate flame

● Group B is a dust, which does not propagate flame

Further testing is required for Group B samples if handled at elevated temperatures >110 degree C.

So what terms do we use to define appropriate sample: particles size (less than 500 micron, potentially explosive, fines less than 100 micron or test sample 63 micron), distribution

usually greater than 30 to 60 g/m3 (you cannot see the hand on the end of your arm), shape (fibre or granular).

Explosion violence falls at higher moisture contents: 0-5% has little effect, 5-10% decreases sensitivity and >25% particles unlikely to stay in suspension.

Where to collect your sample: Horizontal surfaces, girders, floor or inside plant i.e. inside ductwork or inside dust collectors/filters.

Material Safety Data Sheet:

Does the supplier offer an appropriate MSDS? These data sheets are frequently short on specifics:

Minimum Ignition Temperature MIT (cloud) of a dust suspension is the lowest temperature at which it will ignite spontaneously and propagate same. This MIT value is particularly

relevant to problems involving relatively large heated areas of plant e.g. surfaces of dryers, mills, electrical equipment, etc.

Minimum Ignition Temperature: MIT (LIT) 5mm Layer: The test determines the minimum temperature of a prescribed hot surface, which will result in the decomposition and/or

ignition of a layer of powder of specified thickness. The test is particularly relevant to industrial equipment with hot surfaces, on which dust deposits may form. Thicker layers will invalidate the T rating of equipment and may cause ignition.

Dust Minimum Ignition Energy (MIE) Dust Cloud of a dust suspension is the lowest energy at which ignition and flame propagation away from the spark kernel occurs – the value being particularly relevant to identifying potential electrostatic ignition hazards.

Two circuits are employed – capacitive (for electrostatic ignition) and inductive (for friction spark ignition).

In general, three ranges are defined as significant:

1. MIE ≥ 10 mJ normal ignition sensitivity,

2. 3 mJ ≤ MIE < 10 mJ particularly ignition sensitive,

3. MIE < 3 mJ extremely ignition sensitive

Walking across the carpet and touching a metal doorknob can be up to 4 mJ.

A dust is more ignitable at an elevated temperature, i.e. the Minimum Ignition Energy (MIE) is lower.

Concentration Lower Explosion Level (LEL for gases and vapours) or Minimum Explosible Concentration (MEC for powders) is typically of the order 45g/m3 and 30-60 g/m3 respectively. The Upper Explosion Level (UEL) not as clearly defined for powders, but usually is >1000g/m3.

LOC: maximum oxygen concentration in a mixture of a flammable substance and air and an inert gas, in which an explosion will not occur, determined under specified test conditions.

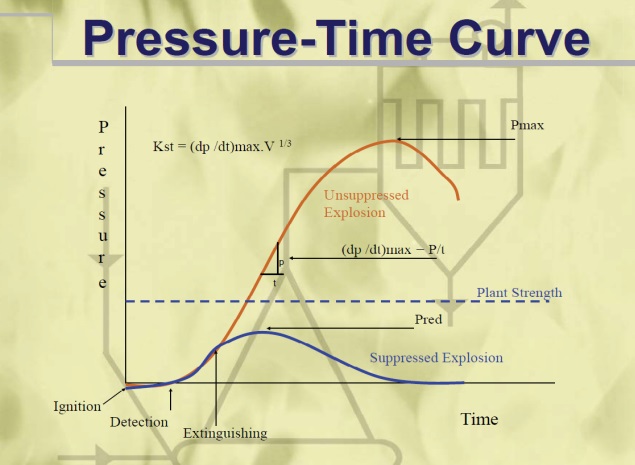

Explosion Characteristics: Kst in bar m/s & Pmax in barg: Although the methods above are relevant for prevention of flame and explosions, to confirm the quantitative assessment of a design for explosion protection, you will need to conduct an actual controlled dust explosion in either the 20 litre or 1m3 test apparatus.

| Material | P/max | Kst bar m/s |

| Methane | 8.4 | 58 |

| Hydrogen | 8.2 | 503 |

| Sugar | 8.0 | 80 |

| Coal | 7.7 | 85 |

| Starch | 9.4 | 150 |

| Cellulose | 10.0 | 160 |

| Milk Powder | 8.2 | 147 |

| Dextrin | 8.7 | 200 |

| Aluminium | 11.5 | 555 |

As shown, dust explosion pressures can reach the same as gases/vapours and some metal dusts can be as dangerous as Hydrogen.

The speed of the flame may be constant but the surface grows exponentially emitting more heat faster in a confined space, this creates pressure which may eventually break the confinement. To design a protection system these terms are essential. Remember the bigger the vessel, the longer it takes to get to its Pmax, unless the plant strength fails first!

Equipment & Hazardous Area Classification

A place in which an explosive atmosphere in the form of a cloud of combustible dust in air is not likely to occur in normal operation (perform their intended function within their design

parameters) but, if it does occur, will persist for a short period only – e.g. outlets from cyclones, clean-side of dust filters, etc.

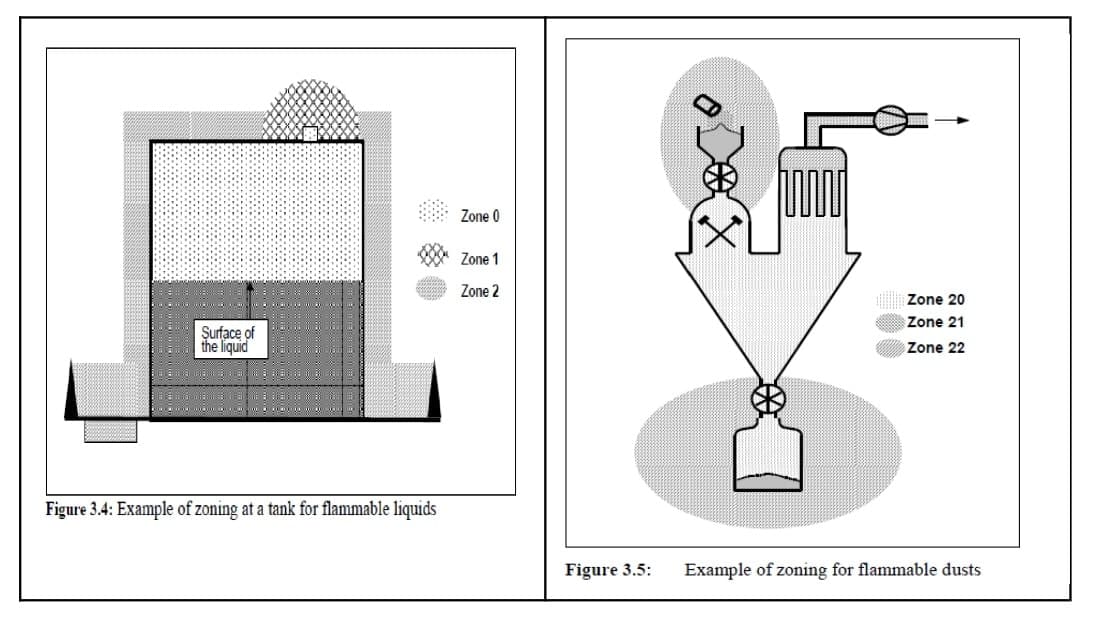

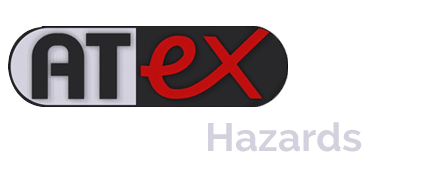

Historically, the following probability values have been used for guidance (with gases/vapours) and these are commonly applied to solids handling also.

1. Continuous Source (> 1000 hrs. yr-1) yields a Zone 0 / 20 with Equipment Cat 1G/D

2. Primary Source (10 – 1000 hrs. yr-1) yields a Zone 1 / 21 with Equipment Cat 2G/D

3. Secondary Source (<10 hrs. yr-1) yields a Zone 2 / 22 with Equipment Cat 3G/D

You must install the appropriate equipment to the designated Zone

Marking of Equipment – Directive 94/9/EC (Annex II, 1.0.5)

- Name/address manufacturer

- CE marking + if appropriate notified body number

- designation of series or type

- Serial number, year of construction

- Ex symbol + EEx

- Category (M1 / M2 / 1 / 2 / 3) for equipment-group II, ‘G’ (gas) and/or ‘D’ (dust)

- Explosion / Ignition protection symbol + (if appropriate) Gas group

- Temperature Class or Temperature

Example: EEx 2 G d IIA T4

Certification ensures that the equipment or protective system is fit for its intended purpose and that adequate information is supplied with it, to ensure that it can be used safely.

Explosion Protection Document (EPD):

The EPD must be drawn up prior to the commencement of work and be revised when the workplace, work equipment or organization of the work undergoes significant changes, extensions or conversions.

The employer may combine existing risk assessments, documents or other equivalent reports and incorporate them into the explosion protection document.

The ATEX Directive allows the Explosion Protection Document to be either a separate document or part of a combined safety report and as a whole must cover both technical and

organisational or procedural aspects of explosion prevention and protection. Thus for the majority of process plant, it is recommended that these two aspects be separated and dealt with in different documents.

More than 2000 incidents of gas, mist and dust/air atmospheres occur annually in Europe, causing injuries, loss in production, plant damage and even death. This is not acceptable

and the introduction of the ATEX & DSEAR regulations should be welcomed.

There are many organisations suddenly offering products and services, which can help you through this, but make sure they are reputable, with a history in explosion prevention and

protection.

The ATEX exercise should be programmed and carried out by the employers, with their workers, to make industry a safer and more profitable experience. To do this it helps if you understand the language of explosion safety today.

Declan Barry, MD of ATEX Explosion Hazards Ltd, entered the Explosion business in 1987. His primary objective is to make industry safer by installing appropriate explosion protection solutions with full back up services. He believes strongly that people cause explosions not equipment, yet there is an over-emphasis in industry on area classification, testing and equipment selection, when he believes that the lack of continuous education and training is the primary cause of dust explosions.

EXPERTS IN EQUIPMENT FOR EXPLOSIVE ATMOSPHERES

LEADERS IN ATEX INNOVATION TO THE HAZARDOUS AREA INDUSTRIES

Thorne & Derrick are leaders in the development and distribution of Product Innovations that deliver significant improvements to clients plant, people and operational safety in the explosive atmosphere industries.

Your proactive problem solvers experienced in succession planning for the replacement of obsolete, non-conformant and legacy equipment in hazardous areas.

Your first-choice provider of innovative and competitive solutions to ensure ATEX & IECEx Compliance for Hazardous Area Electrical, HVAC & Process Instrumentation Equipment to UK and international projects.

Control Panels | Plugs | Isolators | Enclosures & Junction Boxes | Lighting | Control Stations | Motor Starters | Heat Trace | Gas Detection | Flame Detection | Process Instrumentation | Process Heating | Ventilation Fans | Security Access Control

Competitive Prices | Extensive Stocks | Technical Support | Express Delivery