Hazardous Area Locations & Safety In Electrical Installations

Published 11 Jun 2020

Estellito Rangel Jr.

Thorne & Derrick, The Experts in Equipment for Explosive Atmospheres, are privileged to have received permission from Estellito Ranel Jr. to republish this article.

Estellito was the first Brazilian national expert accepted at IEC Technical Committee 31 to provide consultation on the elaboration of the IEC Standards for explosive atmospheres.

The scope of TC31 is to prepare and maintain international standards relating to equipment, such as lighting systems, for use where there is a hazard due to the possible presence of explosive atmospheres of gases, vapours, mists or combustible dusts.

Estellio has over 3 decades industry experience exployed by Petrobras, the Brazilian state owned oil company, working in the following Departments: Engineering, Offshore Platform Utilities Management, Maintenance, Offshore Platform Technical Support, Refinery Electrical Systems Design and E&P Workers’ Safety.

Hazardous Area Locations

Safety In Electrical Installations

The electrical installation in classified locations has additional requirements than those defined for ordinary locations in order to offer no ignition risks for an occasional explosive atmosphere. Electrical and electronic equipment suitable for use in such locations, must have a “Certificate of Conformity” issued by a certification Body duly accredited.

However, in the audits we do in many industries, we still find a large number of non-conformities, originated as in the assembly stage as in maintenance activities.

As such non-conformities affect the safety of the plant (as if their integrity is compromised, electrical equipment can act as source of ignition), we will highlight some points that need special attention.

1. Signage

A worrying factor is the absence of particular signalization in industrial plants.

The directive is: “Safety signs should be clear to all professionals involved in services on classified areas, providing information on the zone classification, the gas group (for flammable gas and also for combustible dust atmospheres) and the allowed temperature class.”

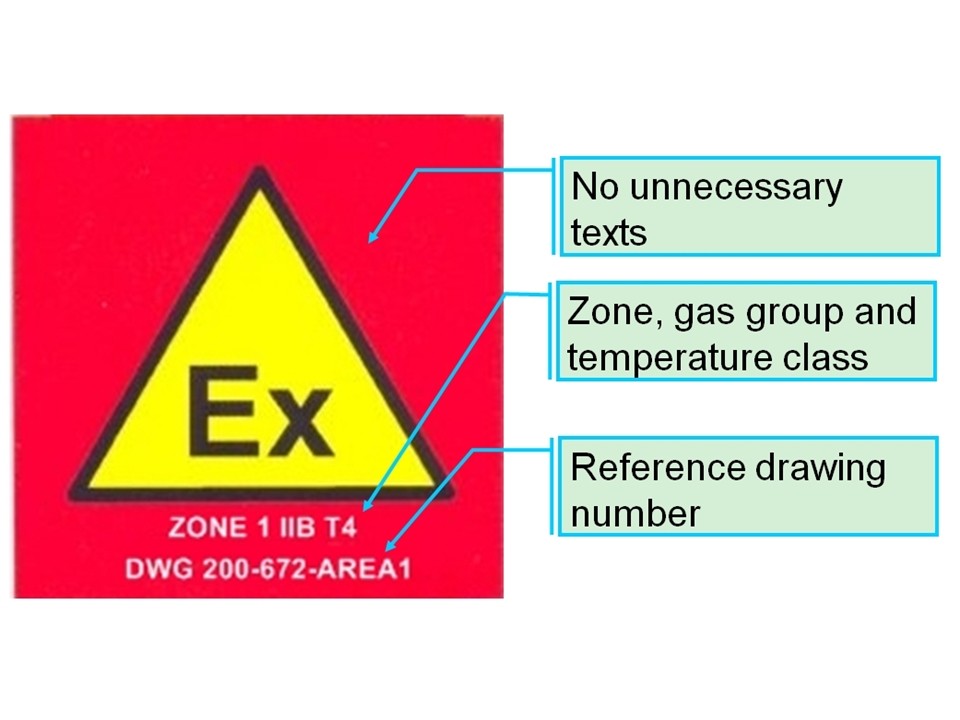

Unfortunately, it can be found in internet many plates that do not comply with ISO requirements. The IEC 61892-7:2014 (a voluntary standard applied only on offshore units), suggested a model for an Ex sign – as shown in Figure 1 – but it has lack of information, as explained below:

Fig 1: A poor model of an Ex sign.

The suggestion above provides only incomplete information for safety, because the essential items for specification of the adequate equipment to be used there, are missed, as:

- Redundancy: The yellow triangle with “Ex” inside, already means “hazardous area”;

- Sometimes the word “danger” is also included, but the meaning of “possibility of an explosive atmosphere” is closer to a “hazard” (risk), than a “danger”;

- Texts require to be written in different languages, in order to be read by foreign workers at a given site;

- No information on the Zone of the location;

- No information on the gas group;

- No information on the temperature class allowed for the location.

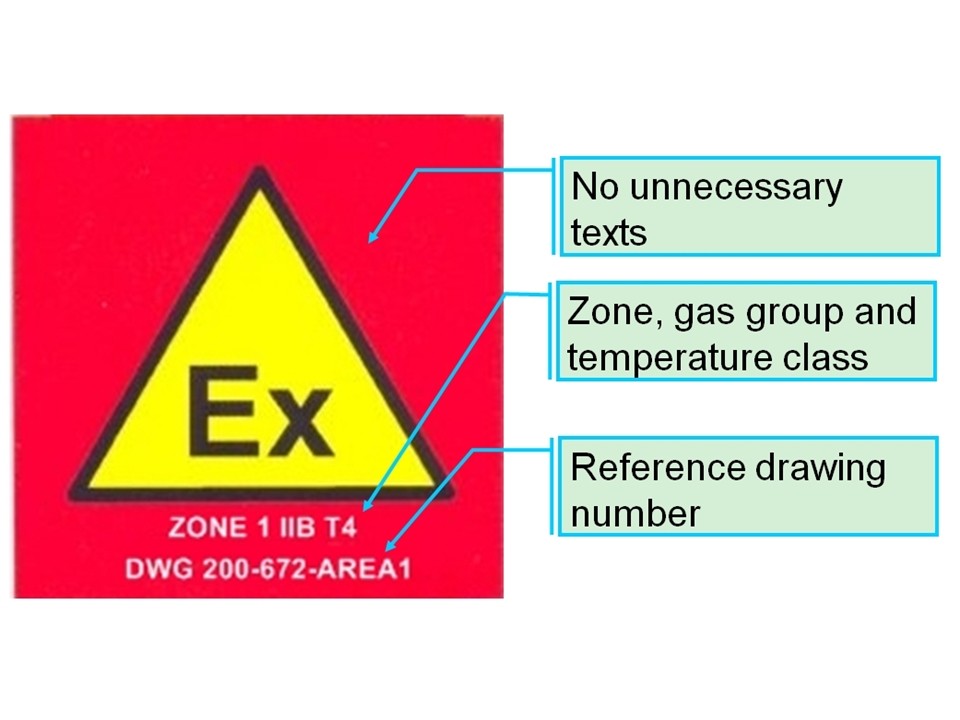

So, in order to provide safety, a comprehensive sign is required, that also includes the classification area drawing number, facilitating the worker to get more details, as Fig 2:

Fig 2: An effective sign model that meets all safety recommendations for signage of hazardous locations, and that was already adopted by many companies, as Petrobras. The red background allows a quick alert and it is recommended by many safety documents.

2. Training the workforce

It is very common to see a lack of specialized professional training on installations in hazardous locations, as contracting companies usually hire electricians with experience on commercial and industrial installations, but without a sound knowledge on requirements for installations in hazardous locations.

And a concern arose in the market since IEC 60079-14:2013 included in its “normative” annex A4 that “The competency of responsible persons, operatives and designers shall be verified and attributed at intervals…” , because at first sight it suggests an association with “personnel certification” and, consequently, with the IECEx Scheme (a commercial branch of the IEC, dedicated to Certification of products, companies, persons and services, based solely on IEC standards, and receiving royalties from each certificate issued).

It is not difficult to find in the internet some misguided information that the “United Nations recommends that scheme“, but in fact, the organization that proposed such recommendation was the UNECE – United Nations Economic Commission for Europe (an UN commission focused on the European economic affairs). The document ECE/TRADE/391 explains the topic at the UNECE website.

In Brazil, some organizations started to offer Ex personnel certification under similar structure to that offered by the IECEx Scheme, but their certificates can’t show that logo if the certification body is not member of the Scheme. As only certifications on the Ex 000 and Ex 001 units are being offered (December 2017), they can’t be considered as “Ex personal certification“, because they are based only on multiple choice tests, without any practical activity assessment.

For example, an Ex installer will need to pass on the units Ex 001, Ex 003, Ex 006 and Ex 008 to be certified, what means that this is an expensive process. In short: companies should invest in effective training of the workforce, because the competence certificates based solely on units Ex 000 and/or Ex 001 by multiple choice tests, do not guarantee that the worker performs his tasks on Ex installations in the proper way.

Photo 1: The “hands-on” training: the effective way to teach the workers on Ex installations.

3. Changes in installations and Ex equipment

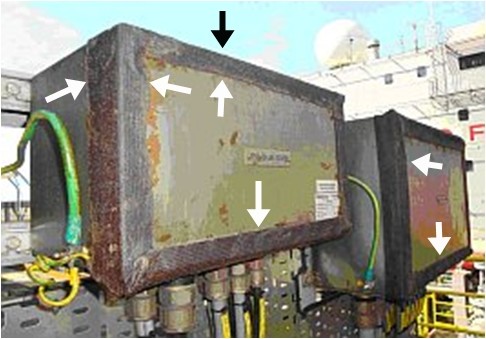

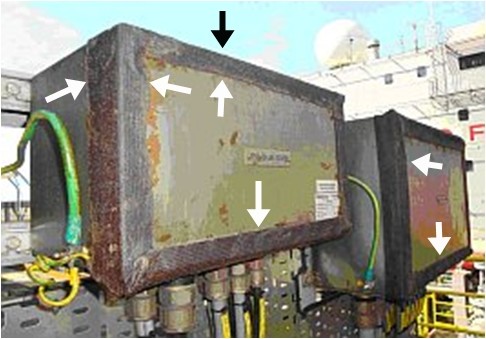

The explosion-proof boxes (Ex d) are designed in a way that the gases resulting from any internal explosion are driven to the outside through adequately designed joints. And it is up to the user to make sure that these joints are at a minimum distance from any solid obstacle, according to the table 13 of IEC 60079-14.

The non-conformity that we will highlight here in Ex d boxes, although allowed by the standard, is a “greased tape” wrapped around the flanged joints, as shown in Photo 2. This practice, according to the CEPEL report DLA 43410/2011, raises at 16% the internal pressure in the propagation test, denoting a risk that was not evaluated in the original Certificate of Conformity of the junction box, and therefore invalidates it! It is clear that changes in equipment and installations can affect the safety of installations and people.

Photo 2: Non-conformity in Ex installations, especially those that violate the provisions of the equipment Conformity Certificate, affects the safety of the industrial plant!

Conclusions

It is essential for all companies that process, store and transport flammable or combustible products, to go beyond the standards’ requirements, prioritizing updated training given by experienced consultants, because training deficiencies lead to non-conformities that cause risks (explosions) with potential to cause damage to workers, installations and neighbouring communities, what may even lead to ceasing the company activities!

References

[1] Electrical installations in hazardous locations: Tackling some controversial IEC recommendations, Estellito Rangel Jr. Electrical Business Magazine

[2] The importance of inspections on electrical installations in hazardous locations, Estellito Rangel Jr., Alan S. Queiroz and Maurício de Oliveira. IEEE paper

[3] Brazil moves from divisions to zones [hazardous location safety], Estellito Rangel Jr. IEEE paper

EXPERTS IN EQUIPMENT FOR EXPLOSIVE ATMOSPHERES

leaders in ATEX Innovation To The Hazardous Area Industries

Thorne & Derrick are leaders in the development and distribution of Product Innovations that deliver significant improvements to clients plant, people and operational safety in the explosive atmosphere industries.

Your proactive problem solvers experienced in succession planning for the replacement of obsolete, non-conformant and legacy equipment in hazardous areas.

Your first-choice provider of innovative and competitive solutions to ensure ATEX & IECEx Compliance for Hazardous Area Electrical, HVAC & Process Instrumentation Equipment to UK and international projects.

Control Panels | Plugs | Isolators | Enclosures & Junction Boxes | Lighting | Control Stations | Motor Starters | Heat Trace | Gas Detection | Flame Detection | Process Instrumentation | Process Heating | Ventilation Fans | Security Access Control

Competitive Prices | Extensive Stocks | Technical Support | Express Delivery