Immersion Heaters In Oil & Gas Applications

Published 31 Mar 2017

Immersion Heaters In Oil & Gas Applications

Immersion Heaters

Oil & Gas Applications

T&D, a leading UK distributor for process heaters including a broad range of immersion heaters, present a Guest Article by Ilan Toledano (Vice President from Wattco) on the use of immersion heaters in the oil and gas industries.

The oil and gas sector in the United States produces petroleum from more than 500,000 wells, overtaking Russia and Saudi Arabia as the largest petroleum producing operation in the world. An additional 4,000 oil and gas platforms as well as 144 refineries operate in the US.

A total of 16,000 domestic facilities produce oil and gas and are involved in the extraction and refinement operations. Shipments produced from such facilities carry a value of more than $150 billion and supply 65% of the nation’s energy [1].

Numerous steps in the oil extraction and refinement process require the heating of vats of liquids to extremely high temperatures.

Traditionally, external boilers heat the vessels despite the inherent heat loss associated with this method. Industrial immersion heaters offer a more efficient means for heating; heat is directly infused to the fluid in which it is immersed, and virtually no heat is lost in the process.

These heaters are so efficient that they require about one third to one half of the wattage typically needed to heat a vat of liquid using traditional industrial heating methods. In the energy industry, such efficiency is critical.

Not only are immersion heaters more efficient than traditional fuel-fired heaters, they reduce the footprint of the heated vessel. By design, immersion heaters are submerged within the fluid they are intended to heat and, therefore, take up no space outside the unit.

Not only are immersion heaters more efficient than traditional fuel-fired heaters, they reduce the footprint of the heated vessel. By design, immersion heaters are submerged within the fluid they are intended to heat and, therefore, take up no space outside the unit.

A control box is accessible externally, allowing engineers the ability to input a desired set temperature and obtain real-time readouts of the current temperature within the unit. In addition to conserving space, immersion heaters reduce risk by eliminating combustible heat sources from the proximity of the process fluid.

Based on the application at hand, a variety of immersion heaters and heater compositions may be appropriate. Flanged heaters and circulation heaters, for instance, each have their own benefits, and each heater may be customised in a number of ways.

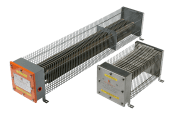

Flanged immersion heaters are the simplest of all, consisting of a tubular heating element attached to a metal flange.

They are the easiest among all immersion heaters to install, maintain, and replace. In instances where fluids must be kept in motion, an electric circulation heater is likely more appropriate.

Circulation heaters consist of the simple and efficient flanged heaters mounted within a steel vessel. Fluid is pumped through the inlet valve of the heater where it is heated by the flanged unit, then sent through the exit valve to its final destination.

As with flanged heaters, circulation heaters are highly customisable depending on the nature of the liquid.

After determining the appropriate type of heater, the composition of the heater may be customised for any application. The heating element can be constructed from stainless steel tubules or from more exotic metals if the fluids being heated are corrosive.

Further, the fluid’s pH, viscosity, target temperature, and flow rate are all properties to consider when designing an immersion heater. Wattco offers a number of off-the-shelf units designed for common industrial jobs, and Wattco engineers possess the experience and expertise to collaborate on a design for even the most unique applications.

[1] United States Environmental Protection Agency. October 19, 2014.

MORE READING

- Benefits of Immersion Heaters In Cold Climates

- Electric Immersion Heaters In Cold Climates For The Oil & Gas Sector

- Immersion Heaters in the Oil and Gas Sector

Who Are Wattco?

Wattco is a manufacturing company developing electric heating products for use around the world since 1969. With uncompromised dedication to customers, Wattco offer solutions and not just products. Wattco development in oil and gas industries, renewable energy, HVAC systems and government projects help customers get alternative solutions for their projects to get off the ground in the most cost efficient way.

Circulation heaters, flanged heaters and industrial immersion heaters are an important heating product of many industries. Wattco heaters are used to prevent freezing and act as a catalyst in many chemical reactions in both the petrochemical industry as well as processing industries. Wattco manufactures electric heating elements for a wide range of applications

ELECTRICAL & PROCESS INSTRUMENTATION EQUIPMENT

FOR EXPLOSIVE ATMOSPHERES

Thorne & Derrick are Specialist Distributors of Hazardous Area & Explosion Proof Equipment with IECEx & ATEX Certifications to the onshore and offshore oil, gas, petrochemicals and process industries.

Key Product Categories: Control Panels | Plugs & Sockets | Isolators | Enclosures & Junction Boxes | Lighting | Control Stations | Motor Starters | Heat Trace Cables & Systems | Gas Detection & Detectors | Fire Detection & Detectors | Heat Detectors | Electrical Heating & Heaters

Trace Heating | System Design & Supply