Immersion Heaters in the Oil and Gas Sector

Published 31 Mar 2017

Immersion Heaters in the Oil and Gas Sector

Immersion Heaters

Oil and Gas Sector

T&D, a leading UK distributor for process heaters including a broad range of immersion heaters, present a Guest Article by Ilan Toledano (Vice President from Wattco) on the use of immersion heaters in the oil and gas industries.

Immersion heaters are utilised in various applications within the industrial manufacturing and industrial processing fields. These heaters are used in a wide range of industries; this includes petroleum, chemical, process heating, oil and gas, and even food industries, with the main purpose of helping keep liquids at the correct temperature.

In the process industry, this is important for several reasons. First, one crucial aspect of any process industry is to keep the flow of production continuous; industrial immersion heaters ensure that substances are not detrimentally altered along the production line due to variances in temperature.

In the process industry, this is important for several reasons. First, one crucial aspect of any process industry is to keep the flow of production continuous; industrial immersion heaters ensure that substances are not detrimentally altered along the production line due to variances in temperature.

Second, many process industries involve large quantities of the given substance, and electric immersion heaters are able to maintain the correct temperature for vast amounts of substances. Finally, electric immersion heaters are a relatively cheap and efficient method of maintaining these substances, meaning that manufacturers have less up-front and long-term costs by using immersion heaters.

One interesting development for electric immersion heaters has been the sharp increase in hydraulic fracturing.

In order to both reduce localised emissions and increase production time (both of which are crucial to process industries) the industry trend has been toward using heat generated from electric sources. This has been just one of the boons for electric immersion heaters in relation to the oil and gas sector.

Forms of Electric Immersion Heaters

Even in industrial settings, electric immersion heaters take on many forms. Immersion heaters can be mounted on a pressure vessel through flanged, circulated, or over the side applications.

Even in industrial settings, electric immersion heaters take on many forms. Immersion heaters can be mounted on a pressure vessel through flanged, circulated, or over the side applications.

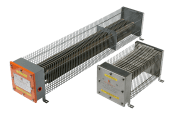

Over the side heaters are perhaps the most basic application, because it requires no special installation and is easily removed for servicing. These are used primarily in tanks, where the heating element is fully immersed in the liquid either on the side or at the bottom of the tank. As the name implies, installing this form of electric immersion heater is as easy as securing it over the side of the tank and fixing the control panel to the exterior.

Flanged heaters are most commonly used in pressure vessels, since it consists of bent tubes that are welded directly into the container.

These flanged immersion heaters are best for pressure vessels because the heat is divided evenly in order to avoid corrosion. Flanged immersion heaters, like over the side heaters, are usually implemented along with accessible controls on the outside of the vessel or tank.

Finally, circulation heaters are relatively compact systems for heating both fluids and gases. Also known as in-line heaters, they are usually utilised for purified gases, de-ionised water and in a semiconductor, because it requires constant movement and is able to heat substances almost immediately.

One major application of this method is also when the substance requires direct heat from a circuit external to the main vessel or tank.

Technical Specifications

The technical specifications of industrial immersion heaters range quite a bit as well, depending on both the type of immersion heater and the specific manufacturer.

Threaded connections, usually consisting of a 2.25-inch pipe, are rated up to 24 kW and over the side heaters are rated up to 36 kW. In contrast, flanged immersion heaters (most commonly used in steam boilers) and circulation immersion heaters (which are essentially built in to the container) are rated up to 2,000 kW.

More reading

- Benefits of Immersion Heaters In Cold Climates

- Electric Immersion Heaters In Cold Climates For The Oil & Gas Sector

- Immersion Heaters In Oil & Gas Applications

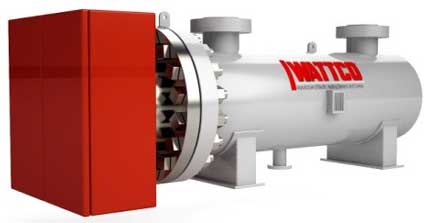

Who Are Wattco?

Wattco is a manufacturing company developing electric heating products for use around the world since 1969. With uncompromised dedication to customers, Wattco offer solutions and not just products. Wattco development in oil and gas industries, renewable energy, HVAC systems and government projects help customers get alternative solutions for their projects to get off the ground in the most cost efficient way.

Circulation heaters, flanged heaters and industrial immersion heaters are an important heating product of many industries. Wattco heaters are used to prevent freezing and act as a catalyst in many chemical reactions in both the petrochemical industry as well as processing industries. Wattco manufactures electric heating elements for a wide range of applications

ELECTRICAL & PROCESS INSTRUMENTATION EQUIPMENT

FOR EXPLOSIVE ATMOSPHERES

Thorne & Derrick are Specialist Distributors of Hazardous Area & Explosion Proof Equipment with IECEx & ATEX Certifications to the onshore and offshore oil, gas, petrochemicals and process industries.

Key Product Categories: Control Panels | Plugs & Sockets | Isolators | Enclosures & Junction Boxes | Lighting | Control Stations | Motor Starters | Heat Trace Cables & Systems | Gas Detection & Detectors | Fire Detection & Detectors | Heat Detectors | Electrical Heating & Heaters

Trace Heating | System Design & Supply