How LED Ex Luminaires Provide A Reliable ATEX Lighting Solution For Crane Applications

Published 24 Sep 2019

LED Ex Luminaires Provide A Reliable ATEX Lighting Solution For Crane Applications

ATEX Lighting Solution For Crane Applications

Lighting for an offshore or marine boom crane is a particularly demanding application. Traditional lighting solutions are unable to be used in these environments where there is exposure to high vibration and where the mounting options are access requiring a hazardous area lighting solution.

A purpose designed LED crane luminaire can overcome both these issues and deliver an improved quality of light for crane operators.

WHY CHOOSE A CUSTOM DESIGNED CRANE LUMINAIRE?

Standard floodlight are used on most crane applications typically metal-halide (HID) or high pressure sodium (HPS), however these aren’t specifically designed

Lighting used on most crane applications tends to be standard floodlighting, typically metal-halide (HID) or high pressure sodium (HPS), which has not been designed with the specific requirements of the application in mind.

To achieve reliable, high quality illumination on a crane boom, it is essential to choose a ATEX lighting solution that has been designed specifically for crane applications.

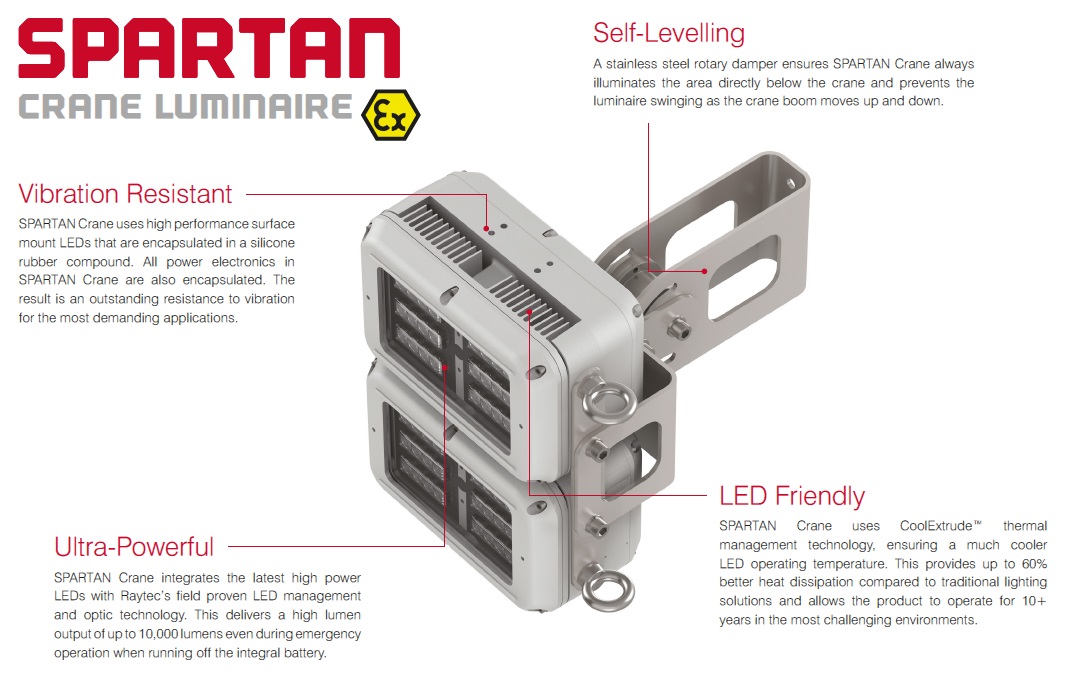

The SPARTAN Crane luminaire is similar in design to the SPARTAN Flood boasting the same features including minimum maintenance, high durability and an in-built resistance to vibration.

Simple additions make the crane luminaire suitable for the demands of crane mounted applications this include a custom designed bracket that has a stainless steel rotary damper.

The rotary damper moves with the crane boom to ensure it always lights the area directly below the crane tip and stops the lighting from ‘swinging’ under movement, which could create a strobing effect which is detrimental to the operator.

Having reviewed the design features of the SPARTAN crane luminaire it is now time to take a look at the features of an LED crane in contrast to the traditional technology.

Zone 1 Crane Floodlight ATEX

QUALITY & DISTRIBUTION OF LIGHT

The colour temperature of the light is the biggest variant between traditional crane lighting and an LED Crane luminaires.

LED fittings use a higher ‘daylight’ temperature (easier for the human eye) whilst the more traditional floodlights (HID and HPS) provide a ‘warmer white’ colour. LED’s are most cost effective as they reduce the probability of failures and do not leave a site in darkness or lacking in light for long periods of time like traditional light fittings.

This has a significant impact from a health and safety perspective and increases the level of risk on-site, worsened under emergency conditions.

The height of the crane boom has to be considered when looking into the distribution of light. The highly diffused light produced by HID and HPS lamps often washes out and provides inadequate light levels on the load and load target.

Using LED technology limits the wasted light as improvements in the operational light benefit from the technological advancements.

LED Crane lighting delivers precision when it comes to the distribution of light in the load and on the workstation or facility. This increases visibility and site safety as the crane operator is likely to be blinded by the light when looking at the load.

The SPARTAN Crane luminaire uses a narrow beam pattern as standard, generating enough light on the load and load target regardless of the elevation of the crane boom.

Circular and elliptical beam pattern are also an option: circular maximises light output whilst elliptical beam patterns use Raytec’s revolutionary VARIO holographic lens technology to shape the light. This decreases energy wastage, enables longer illumination distances and limits the light output lost.

The VARIO holographic beam patterns can easily be modified for any angle – offering ultimate flexibility to specifiers, distributors and end-users.

SPARTAN Crane by Raytec | High Power Floodlight Zone 1 – standard or emergency variant lights with high lumen output of up to 25,000 delivered lumens. SPARTAN floodlights are globally certified for all Zone 1, Zone 2 and Industrial lighting applications

VIBRATION

Crane applications invlove frequent movement and lifting of cranes so the floodlights need to be robust and be able to offer protection against high levels of vibration. LEDs are encapsulated in a silicone rubber compound with a natural resistance to vibration unlike traditional lamps.

All power electronics in SPARTAN are also encapsulated. The result is an outstanding resistance to vibration for the most demanding applications.

While all LEDs are naturally resistant to vibration, the SPARTAN Crane luminaire uses high performance surface mount LEDs that are encapsulated in a silicone rubber compound. All power electronics in SPARTAN are also encapsulated. The result is an outstanding resistance to vibration for the most demanding applications.

MAINTENANCE

The number of replacement lamps depends on the lighting used. Traditional light fittings require a lot more maintenance and lamp changes over the lifespan due to environmental factors and vibration.

However long life LED’s reduce maintenance costs over the light fittings life span an incredibly important feature in crane lighting applications. The installation of the light to the boom tip further increases the difficulty of maintenance of these light fittings.

Due to the effects of the working environment and vibration, traditional crane lighting will require frequent maintenance and relamping with each fitting going through a number of replacements over the course of its operational life.

The SPARTAN Crane luminaire provides a solution to this by using the latest Platinum Elite SMT LEDs and providing an operational life of over 100,000 hours. In the event that maintenance is required, SPARTAN’s unique modular design makes maintenance far easier and means it can also be carried out on-site.

The Crane luminaire also uses the same core power supply components as SPARTAN Flood which allows one stockpile of spare parts to be kept on-site to service multiple variants of different SPARTAN luminaires.

SPARTAN Crane by Raytec Floodlight Zone 2 – with high lumen output of up to 10,000 delivered lumens. SPARTAN floodlights are globally certified for all Zone 2, Zone 22 and Industrial lighting applications

DURABILITY

Durability is key when lighting offshore cranes as hazardous conditions such as severe temperatures, threat of exposure to vibration, danger of corrosion due to the marine environment and the fact that the electrical supply on a crane is prone to fluctuating which causes electrical stress and early failures. The SPARTAN Crane luminaire is designed with these conditions specifically in mind.

Designed to protect against vibration the SPARTAN Crane also has a marine grade aluminium body for safety against extreme conditions, an operating temperature suitable for up to +55° making this light fitting by far more robust than the majority of alternatives on the market.

CoolExtrude™ thermal management technology also ensures a much cooler LED operating temperature, and as a result provides up to 60% better heat dissipation compared to traditional lighting solutions, allowing the product to operate for 10+ years in the most challenging environments. These design features dramatically reduces the risk of damage during transportation, installation, and operation, even in an environment as demanding as an offshore crane.

Lighting Fittings Linear | High Bay | Bulkhead | Floodlights | Zone 1 & Zone 2 Hazardous Area Lighting

ELECTRICAL & PROCESS INSTRUMENTATION EQUIPMENT

FOR EXPLOSIVE ATMOSPHERES

Thorne & Derrick are Specialist Distributors of Hazardous Area & Explosion Proof Equipment with IECEx & ATEX Certifications to the onshore and offshore oil, gas, petrochemicals and process industries.

Key Product Categories: Control Panels | Plugs & Sockets | Isolators | Enclosures & Junction Boxes | Lighting | Control Stations | Motor Starters | Heat Trace Cables & Systems | Gas Detection & Detectors | Fire Detection & Detectors | Heat Detectors | Electrical Heating & Heaters

Trace Heating | System Design & Supply

Further Reading

-

Raytec ATEX Floodlight Crane Zone 2 SPX-FL48C

Size: 329.32 KB

Raytec ATEX Floodlight Crane Zone 2 SPX-FL48C

Size: 329.32 KB

-

Raytec ATEX Floodlight (Crane) Zone 2 SPZ-FL48C

Size: 475.54 KB

Raytec ATEX Floodlight (Crane) Zone 2 SPZ-FL48C

Size: 475.54 KB