New Zoned Safety Approach Reduces Complexity for Functional Safety of Machinery

Published 03 Jul 2020

A White Paper From ASCO by Jeff Welker, ASCO

Introduction

For both original equipment manufacturers (OEMs) and users, there is considerable interest and focus today on production machine safety.

Manufacturing companies must ensure the health and safety of employees who are involved in the installation, operation, adjustment, and maintenance of production equipment.

This emphasis on safety includes all industries using machines which incorporate pneumatic systems such as automotive, pharmaceutical, process, packaging, stamping, tyre production, assembly operations and general machining.

OEMs and end users must work together in the quest to achieve an accident-free workplace. While it is the end-user which is responsible for training employees in safe work practices, the OEM must design and build a machine that is both safe and compliant with government and industry regulations and directives.

In order to accomplish this task, an OEM must conduct a Risk Assessment to identify which health and safety risks exist. Then the machine must be designed and constructed using methods to reduce the potential risk.

Over the last 2 decades, standards have evolved a great deal to guide OEMs in producing safe equipment. In Europe, Machinery Directive 2006/42/EC became law in 2009. This Directive is intended for manufacturers, importers, and dealers of machinery and safety components and applies to all new machines either built or used in Europe. It coordinates the level of safety of products designed and produced by different manufacturers.

The Machinery Directive is supported by various standards. For example, ISO 13849-1 covers the design and construction of safety-related parts of control systems for machinery. These include basic concepts, principles for design, and engineering aspects that can be applied to production equipment to satisfy machinery safety.

ISO 13849-1 introduces three key concepts for the design of machinery and their safety functions:

- The use of a risk analysis prior to design

- Consideration of the quantitative aspects of the safety functions as well as a qualitative approach

- The use of performance levels (PL) to assess the ability of safety-related parts of control systems to perform a safety function under foreseeable conditions. They are defined in terms of probability of dangerous failure per hour

Even though the Directive has been implemented in Europe, there is still some confusion about applying it in North America.

When designing machinery which uses pneumatic components, engineers typically employ discrete safety circuits with redundant dump valves to meet the obligatory safety requirements. While this approach has been successfully used for many years, it can add some complexity to machine designs.

In response to this, a new concept has emerged called Zoned Safety.

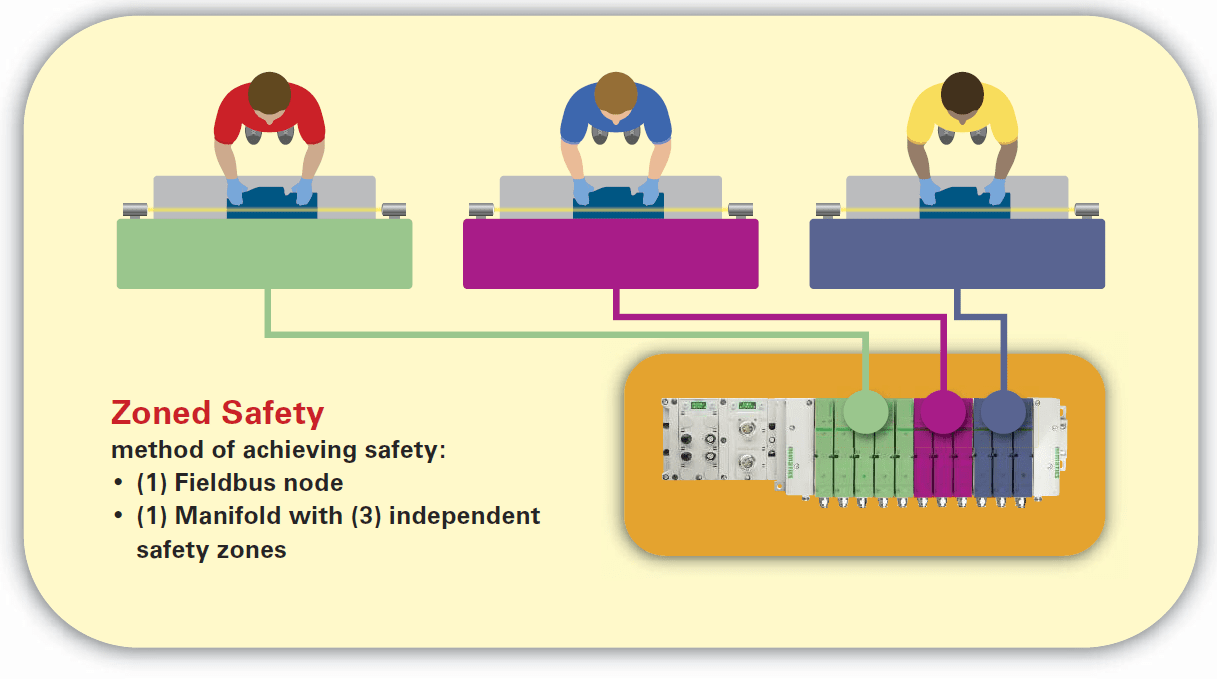

This concept allows the integration of safety functionality within a pneumatic valve manifold. It gives the designer the capability to create multiple zones or sections within a manifold that can be dedicated specifically to safety functionality.

Zoned safety allows the designer to “zone” one or more sections of the manifold to render a specific part of the machine safe. This zoned safety manifold concept provides for operation or functionality while also allowing for a “safe” condition within a zone or section of a machine where and when an operator may be present.

This approach should not be confused with Lockout-Tagout (LOTO), which is a mode used when a machine is being serviced. In this mode, maintenance personnel engage the dump valve in the machine’s pneumatic system, removing and exhausting compressed air energy. Then, the machine power is disconnected and a physical lock is installed on the dump valve. This ensures that the machine’s pneumatic system cannot be inadvertently restarted.

Zoned safety offers many benefits over traditional discrete safety circuits, while allowing for adherence to the Machine Directive and ISO 13849-1 requirements.

Traditional Pneumatic Safety Circuit Design – Using Redundant Safety Dump Valves

Imagine a production line with an operator loading a part inside a welding machine. When the operator enters or reaches into the machine environment, all equipment motion must stop in order to ensure the safety of the operative.

Previously, this has been done by dumping the air to the entire machine’s pneumatic system. To do this, equipment designers typically employ redundant safety dump valves and other complementary products at each operation. These components implement the safety circuitry which shuts off the pneumatic system’s air supply, dumps the air and disables the operation.

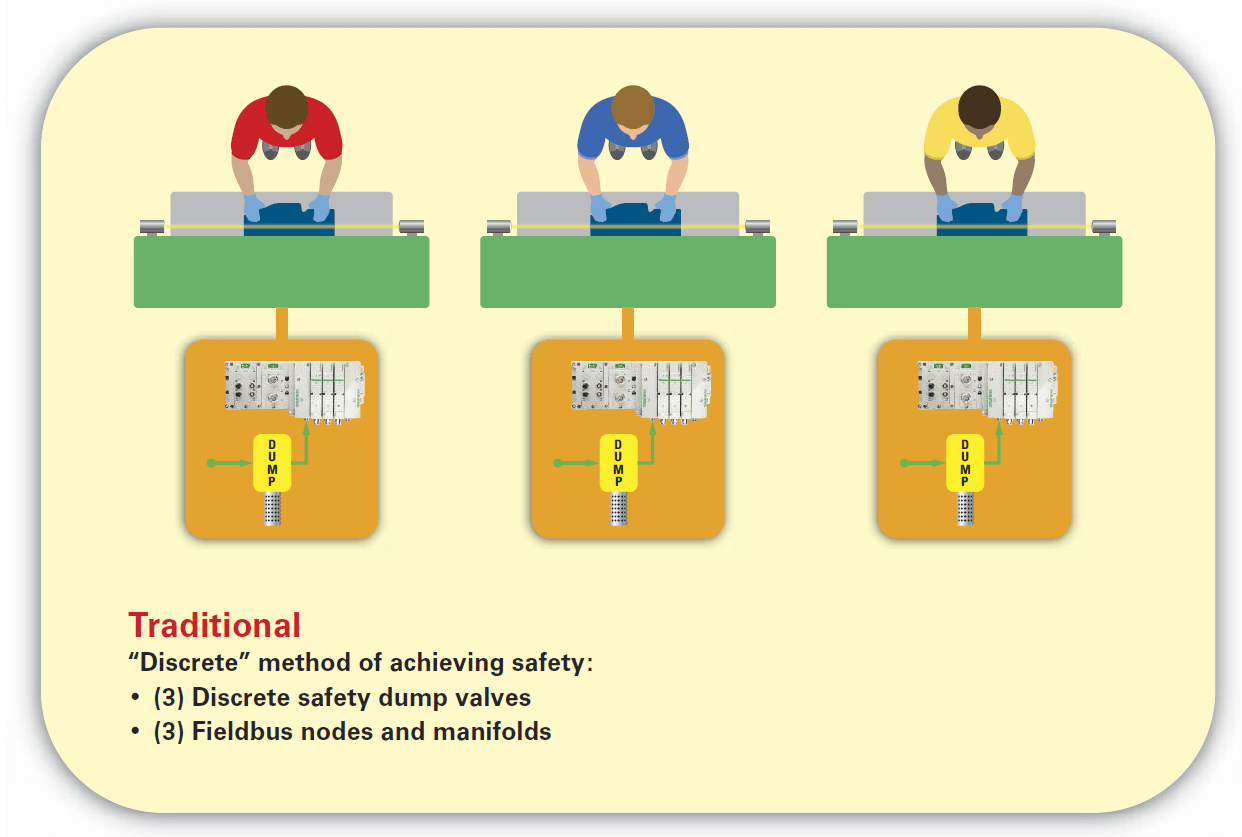

However this solution can add significant complexity to the design, manufacture, and installation of the machine. Also worth noting, when used in a continuous cycle fashion as identified below (figure 1), a redundant dump valve’s life cycle capability may not allow the user to achieve the required PL level.

Employing a redundant safety dump valve at each operation to meet the ISO 13849-1 standard also adds unnecessary cost.

Figure 1: Traditional Method

A Better Way to Achieve Safe Machine Operation

Although dumping air to an entire machine has historically met safety requirements, we know there are times when only one section of the machine needs to be safely disabled while keeping the rest of the machine in operation.

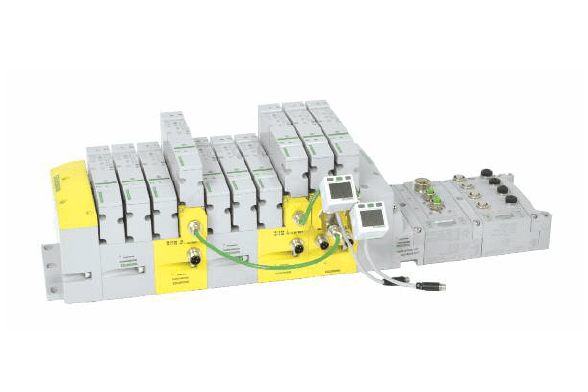

With this goal in mind, ASCO Numatics engineers have pursued a simpler and less expensive approach to safety that would meet the requirements of the Machinery Directive and ISO 13849-1. The result was the Numatics 500 Series zoned safety manifold, an integrated scalable approach to safety control. This means multiple safety zones have the ability to have separate and redundant features for each of the safety circuits, whilst allowing non-safe zones to co-exist on the same zoned safety manifold. This taking full advantage of the existing communications and I/O components.

The Numatics 500 Series valve manifold with G3 fieldbus electronics is the platform that delivers zoned safety. It has the ability to control and reliably disable multiple and independent groups of pneumatic valves that operate a section of a machine.

By using the 500 Series’ capability to integrate up to three electro-pneumatic safety zones within one manifold assembly, both air and power are disabled only to the components in the zones that control equipment that will come in contact with the operator. The rest of the machine can remain in operation when these safety circuits are enabled. (See figure 2.)

Figure 2: Zoned Safety Method

As zoned safety capability is designed into the standard Numatics 500 Series valve manifold platform, no redesign or safety redundant dump valve is required for zone control and the user has a range of choices when selecting valve options, accessories, and flow requirements. The assembled product is very similar to a standard manifold that has been used by OEMs and machine builders for many years.

The Benefits for OEMs and End-Users

There are multiple benefits to be derived from the zoned safety manifold concept. The most important is the ability to greatly simplify the design of a redundant pneumatic safety circuit by using a manifold system.

No longer is a discrete safety circuit, with multiple redundant dump valves and other components which add complexity and expense, required to isolate sections of the machine safely. Multiple independent safety circuits can easily and cost effectively be designed into a single pneumatic valve manifold. This can reduce the number of safety system components by up to 35%. It also optimises the use of safety networks and requires less plumbing.

The zoned safety approach can shrink the size of the safety system and frees up valuable space within the machine and manifold to be used for other purposes.

For most OEM machine builders, designing multi-zoned safety circuits with a Numatics 500 Series manifold will be a familiar and user-friendly experience. Only the ability to redundantly remove power and pilot air to the safety system valves has been added. In addition, the product selection and ordering process is very similar to purchasing a standard Numatics 500 Series valve manifold.

For equipment operators and owners, zoned safety will simplify and reduce costs while still optimising the safety of their machines. Best of all, productivity and asset availability will be improved, as the user does not have to shut down the entire machine when safety circuits are enabled.

Conclusion

The implementation of the Machine Directive 2006/42/EC and ISO 13849-1 has put an emphasis on the design and manufacture of safe production equipment.

Traditionally, discrete pneumatic safety circuits use dump valves and other components to achieve diverse redundancy. However, these safety systems are complex, costly, and frequently require the shutdown of the entire production machine.

ASCO engineers have developed a new approach called zoned safety. This concept leverages the unique capabilities of the Numatics 500 Series valve manifold.

The 500 Series can create up to three independent electro-pneumatic safety zones, while also allowing independent non-safe sections to co-exist within one manifold assembly. Air and power are disabled only to the components controlling equipment that might come in contact with the operator. The rest of the machine can remain in operation when these safety circuits are enabled. Zoned safety greatly simplifies safety circuit design and reduces the number of system components.

Its use is strongly recommended for any pneumatically controlled production equipment requiring Machine Directive 2006/42/EC and ISO 13849-1 compliance.

ASCO Valves

Applying Zoned Safety in an Automotive Workflow

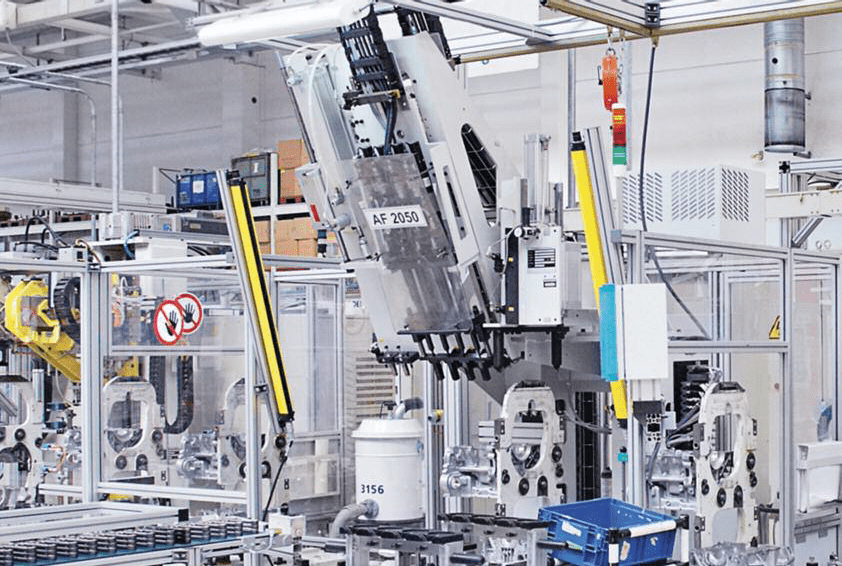

An automated machine has three loading stations. As parts move down the line, an operator adds a stamped metal part to the welded assembly. In order to avoid injury, the operator should not put his hands into the active loading area. To ensure safety, the operator must walk through a light curtain that disables the power and pilot air (only to the redundant pneumatic valves controlling the moving components in the work station), preventing unwanted motion. He loads the part into a fixture, walks back out through the light curtain, initiates operation, and the machine restarts.

The operator’s safety must be guaranteed while in the loading zones per the Machine Directive and ISO 13849-1.

The operator’s safety must be guaranteed while in the loading zones per the Machine Directive and ISO 13849-1.

The conventional way to implement a safety function would be to have one manifold dedicated to the safety circuit in the first loading station. Feeding that manifold would be an expensive redundant safety dump valve. A duplicate manifold and dump valve would be installed for the safety circuits in the second and third loading zones, as well.

With the zoned safety approach, a much simpler design is possible which allows safety operation without the need to dump air to the entire manifold.

Three independent zones within a single Numatics 500 Series manifold would independently control the safety function in the three loading stations. The additional manifolds, dump valves, and fieldbus nodes shown in Figure #1, would not be required.

Explosive Atmosphere Experts

Thorne & Derrick are Specialist Distributors of Hazardous Area Electrical, HVAC & Process Instrumentation Equipment with IECEx & ATEX Certifications to the onshore and offshore oil, gas, petrochemicals and process industries.

We supply major UK and international infrastructure projects and also MRO (Maintenance, Repair, Operations) requirements for both planned and unplanned plant shutdowns – we react with a rapid response to customer demand to ensure downtime is minimised and reliable Power, Light & Heat is restored or provided.

We distribute Innovative products to manage the planned replacement of legacy equipment conformant with international classifications including ATEX and IECEx.

Key Product Categories: Control Panels | Plugs & Sockets | Isolators | Enclosures & Junction Boxes | Lighting | Control Stations | Motor Starters | Heat Trace Cables & Systems | Gas Detection & Detectors | Fire Detection & Detectors | Heat Detectors | Electrical Heating & Heaters

➡ Also Process Instrumentation Products: Ashcroft Pressure Gauges | ASCO Valves | Katronic Flow Meters | KROHNE Flow Meters | VEGA Level Sensors | Rotronic Temperature & Humidity Sensors

Further Reading

-

Asco Numatics Series 500 Zoned Safety Catalogue

Size: 7.39 MB

Asco Numatics Series 500 Zoned Safety Catalogue

Size: 7.39 MB