ASCO EV 8314 Ex Proof ATEX Solenoid Valve (Explosion Proof Encapsulated Coils)

T&D – ASCO Numatics Authorised Distribution Channel. Process and flow control of air, gas, water, oil and steam using advanced solenoid valve technology.

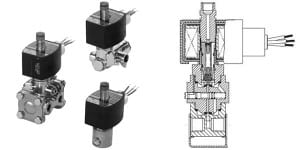

ASCO EV 8314 Explosion Proof Encapsulated Coils

ASCO EV 8314 explosion proof encapsulated coils are part of the hazardous area solenoid valve range suitable for use in ATEX Zone 1 and Zone 2 hazardous area applications.

The molded one piece ASCO valve features a highly efficient solenoid cartridge with a special low wattage coil and has increased ambient temperature capabilities up to 80°C.

Designed for use in the automation of plant controls, the ASCO EV 8314 provides:

- PLC compatibility

- Reduced battery drain

- Reduced heat rise

- Reduced wiring cost

- SIL 3 capable valves

The wide selection of solenoid valves includes 2/2 Normally Closed, 3/2 Normally Closed (including Quick Exhaust), 3/2 Universal and 4/2 with Single or Dual Solenoid – aluminium, brass and stainless steel valve options.

ASCO 8314 Hazardous Area Solenoid Valve With Manual Operator

The nominal ambient working temperature ranges for the ASCO EV 8314 hazardous area solenoid valve are -40˚C to 80˚C (-40˚F to 175˚F).

ASCO EV 8314 solenoid valve is intended for use with clean, dry air or inert gas that has been filtered to 50 micrometers or better. In order to prevent freezing, the dew point should be -8°C below the minimum temperature to which any portion of the clean air or gas system could be exposed.

ASCO EV 8314

Solenoid Valve HAZARDOUS area Certifications

CSA UL FM ATEX IECEX

| ASCO Valve Series | Type | Pipe Size (in) | Max. Cv (Kv) |

CSA |

UL FM |

ATEX IECEx |

| ASCO EV 8314 | 3-Way Valve | 1/8-1/4 | 0.2 (.17) | ✓ | ✓ | ✓ |

Contact T&D for copy hazardous area certificates – for complete technical specification and certification refer to the ASCO EV 8314 download opposite.

Hazardous Area Classification ATEX

ATEX IECEx Certified Valves

ATEX II 2G Ex d mb IIC T

ATEX Gb II 2D Ex mb IIIC T Db IP67

Hazardous Area Classification IECEx

IECEx Ex d mb IIC T

IECEx Gb Ex mb IIIC T Db

ASCO EV 8314 Hazardous Area Solenoid Valve Construction

| Valve Parts In Contact With Fluid | ||

| Solenoid Valve Body | Brass | Stainless Steel |

| Seals and Discs | NBR, FKM, CR, as listed | |

| Sleeve | 304L Stainless Steel | |

| Core and Plugnut | 430F Stainless Steel | |

| Core Springs | 302 Stainless Steel | |

| Pilot Seat Cartridge (Series 8316 & 8344 only) | CA | |

| Rider Rings | PTFE | |

| Spring Retainer | CA | |

ASCO Solenoid Valves, Coils & Enclosures With IECEX & ATEX Hazardous Area Approvals

HAZARDOUS AREA VALVES

ASCO solenoid valves provide flow control in hazardous area industries including oil, gas, petrochem, mining, power and process industries to ATEX (European), IECEx (International), CSA (North America), UL (United States & Canada), NEPSI (China), INMETRO (Brazil) and TR CU (Russia) approvals.

- Standard 3-way and 4-way solenoid valves

- Direct-acting and pilot-operated solenoid valves

- Manual reset and NAMUR valves

- Rugged 316L stainless steel valves for harsh environments

- Low Power Intrinsically Safe and Non-Incendive valves

- Low temperature solenoid valves down to -58°F (-50°C)

➡ Did you know? T&D are Trained users of Thermon CompuTrace software to enable the design of steam and electric trace heating systems for frost protection and process temperature maintenance of pipework in industrial and hazardous area locations.

➡ Read Blog: ATEX Solenoid Valves – ASCO Valves for International Hazardous Area Installations