Crowcon Xgard Bright Gas Detector

Crowcon Xgard Bright Gas Detector with MPS Technology

FIXED GAS DETECTORS | XGARD Bright

Single Gas & Multi-gas Detectors | Fixed Point Gas Detection & Portable Gas Safety Applications | Industrial Locations & Hazardous Area Zones

Crowcon Xgard Bright | ATEX Zone 0, Zone 1 & Zone 2 Hazardous Areas

Crowco Xgard Bright is a versatile platform fixed gas detector offering flammable and toxic gas detection and oxygen monitoring, while providing ease of operation and reduced installation costs. Providing analogue 4-20mA and RS-485 Modbus signals as standard, Crowcon Xgard Bright comes with an Alarm and Fault relay as standard as well as optional HART communications.

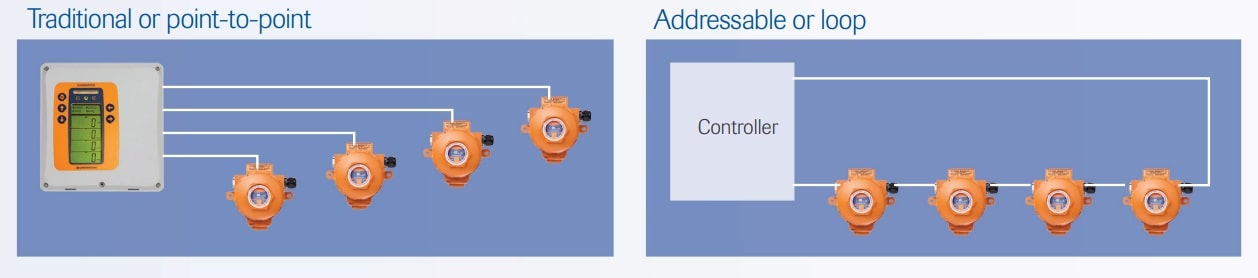

Lowering the cost of installation, the 4-wire addressable implementation drastically reduces cabling requirements. The large OLED display allows users to easily work with Xgard Bright during install, calibration and routine maintenance without the need to open the housing.

This flameproof (Exd) detector is housed within our high-grade aluminium alloy case. Certifications include gas and dust approvals for ATEX and IECEX with UL gas certification in progress.

Crowcon is pioneering advanced molecular property spectrometer (MPS™) sensor technology that detects and accurately identifies over 15 different flammable gases in one device. Now available in Crowcon’s flagship Xgard Bright fixed detector.

Crowcon Gas Detectors with MPS sensor technology

CROWCON XGARD Bright

KEY FEATURES

Meet the next generation of flammable gas detection

The Xgard Bright is now available with MPS (Molecular Property Spectrometer™) technology

- Sensor Poisoning is solved

- Zero calibration for 5 years

- TrueLEL™ multi-gas accuracy

- Hydrogen ready

Versatile:

- Flammable and toxic gas detection and oxygen monitoring – Reducing training requirements across sites

- Choice of M20 or ½”NPT connection – Supports multiple site requirements

- Low power requirement (~3W max) – Reducing site-wide power consumption

- IP65 or IP66 rating (with weatherproof cap) – Allows use in areas subject to regular wash downs or in exposed environments

Ease of installation and operation:

- Addressable – Drastically reduces the amount of cabling needed for multi-point installations

- Local display – Delivers gas level indication, status and supports maintenance routines

- Non-intrusive calibration – Removes the need to open the cover for calibration

- Plug in type terminal blocks – Making wiring quick and easy reducing installation costs

- Configuration via magnetic key – Reducing the amount of time operators spend in a hazardous area

Technical Specification

| Size | 156 x 166 x 109mm (6.1 x 6.5 x 4.3inch) |

| Cable Entry | 2x M20 (stopping plug fitted to left-side entry) |

| Power | 10-30Vdc. 3W max |

| Electrical Output | 4-20mA current sink or source RS-485 Modbus RTU HART (Optional) |

| Weight | Aluminium alloy 1kg (2.2lbs) |

| Enclosure Material | ADC 12 aluminium alloy |

| Relay | Alarm 1, Alarm 2, Fault SPST contacts rated 1A 30Vdc |

| Sounder Out | 24Vdc (nominally), 250mA maximum load |

| Operating Temperature | -40°C to +70°C (-40°F to 158°F) Note: sensor operating temperatures vary widely. Refer to the sensor module datasheet or contact T&D for specific sensor data |

| Humidity | 0 to 95% RH, non-condensing |

| Repeatability | +/- 2% FSD |

| Zero drift | +/- 2% FSD per year maximum |

| Ingress protection | IP65 (IP66 with weatherproof cap) |

| Approvals | ATEX and IECEx Ex II 2 G Ex db IIC T6 Gb Ex tb IIIC T80ᶜ Db II 2 G Ex db IIC T6 Gb II 2 D Ex tb IIIC T80ᶜ Db Certificate numbers: TUV 16 ATEX 7908 X IECEx TUR16.0035 X |

| EMC Compliance | EN50270: 2015 |

| Standards | EN60079-0 :2012 + A11:2013 EN60079-1 :2014 IEC60079-0 :2011 Edition 6 IEC60079-1 :2014 Edition 7 |

| Zones | Certified for use in Zone 1 and Zone 2 areas |

Gas and Ranges For Xgard Bright

| Gas | Units | Max Range |

Standard Range |

Alarm 1 level |

Alarm 2 level |

Temp range °C |

| MPS Flam | %LEL | 100 | 100 | 20 | 40 | -40 to +75 |

| Oxygen (O2) | %Vol | 30 | 25 | 19 (falling) | 17 (falling) | -20 to +50 |

| Carbon Monoxide (CO) | PPM | 1000 | 250 | 30 | 200 | -30 to +50 |

| Hydrogen Sulphide (H2S) | PPM | 100/200 | 25 | 5 | 10 | -30 to +50 |

| Hydrogen (H2) | %LEL | 100 | 100 | 20 | 40 | -40 to +75 |

| Methane (CH4) | %LEL | 100 | 100 | 20 | 40 | -40 to +75 |

| Pentane (C5H12) | %LEL | 100 | 100 | 20 | 40 | -40 to +75 |

| LPG | %LEL | 100 | 100 | 20 | 40 | -40 to +75 |

| Carbon Dioxide (CO2) | %VOL | 0-5% | 0-5% | 0-2% | 0-3% | -20 to +50 |

| PID (VOC) – Safe Area | PPM | 1000 | 1000 | 30 | 50 | -20 to +50 |

| Infra Red Methane (CH4) | %LEL | 100 | 100 | 20 | 40 | -40 to +75 |

| Infra Red Propane (C3H8) | %LEL | 100 | 100 | 20 | 40 | -40 to +75 |

| Ammonia (NH3) – Safe Area | PPM | 100 | 50 | 25 | 25 | -20 to +40 |

| Chlorine (CL2) – Safe Area | PPM | 10 | 5 | 1 | 3 | -20 to +40 |

| Ozone (O3) – Safe Area | PPM | 1 | 1 | 0.1 | 0.2 | -20 to +40 |

| Sulphur Dioxide (SO2) – Safe Area | PPM | 100 | 10 | 1 | 1 | -30 to +50 |

| Infra Red Butane (C4H10) | %LEL | 100 | 100 | 20 | 40 | -40 to +75 |

| Infra Red Pentane (C5H12) | %LEL | 100 | 100 | 20 | 40 | -40 to +75 |

| Infra Red LPG | %LEL | 100 | 100 | 20 | 40 | -20 to +55 |

Reducing the time operators spend in potentially hazardous areas:

At Crowcon we recognize the challenges faced and processes required every time an operator enters a facility or site that has been classified as a hazardous area. Permits are needed, specific training and equipment are required and procedures have to be followed. This consumes resources, which ultimately increases the cost of operations.

Xgard Bright has been designed with this in mind, making routine calibration and maintenance operations quick and simple to reduce the time operators spend in hazardous areas:

- Non-intrusive calibration – Zero and calibration functions (plus setup, tests and adjustments) are performed via the display using the magnetic wand, without needing to open the housing reducing the need for a hot work permit

- OLED display – The brightly illuminated “organic light-emitting diode” display clearly indicates the gas level and units as well as providing comprehensive menus for setup and diagnosis. In low ambient light conditions, such as a dark room, the OLED display achieves a much higher contrast ratio than an LCD used on conventional gas detectors

- Addressable communications – Xgard Bright detectors can be connected on an addressable network using RS-485 Modbus. This option significantly reduces cable and installation costs, while increasing the flexibility and functionality of the wider system

Visit hazardous area gas detectors for explosion and flameproof gas monitoring and detection instruments with certification for potentially explosive atmospheres, including Zone 1 and Zone 2 (according to ATEX and IECEx) and Class/Division categories (according to North American standards).

T&D provide competitive prices and delivery for all Crowcon Gas Detectors, including the Crowcon Xgard Bright.

T&D Sales Team are certificated by Crowcon to support the specification and supply of their flammable and toxic gas detectors. Additionally, T&D are CompEx certified and competent in understanding hazardous area classifications and site requirements for the sale of explosion and flameproof equipment.