Detecting Gas | SafEye Quasar 900 Fixed Gas Detectors

Open Path Gas Detectors | Crowcon SafEye Quasar 900

SafEye Quasar 900

Detecting Gas

Open Path Gas Detection System | Continuous Monitoring for Combustible Hydrocarbon Gases

The SafEye Quasar 900, manufactured by Crowcon, is an open path fixed gas detection system. It employs “spectral fingerprint” analysis of the atmosphere using the Differential Optical Absorption Spectroscopy (DOAS) technique when detecting gas.

➡ Differential Optical Absorption Spectroscopy (DOAS) is used to measure concentrations of trace gases.

SafEye Quasar 900 offers the very latest open path IR technology which detects a wide range of hydrocarbon gases including alkanes (methane to hexane) and ethylene.

Quasar 900 models can be tailored to protect specific high-risk installations. Reliability and performance is key and consequently is assured with SIL2 approval and successful 3rd party FM performance/function testing to FM and EN standards.

With a range from 7m up to 200m the Crowcon Quasar 900 detects gas hazards in extremely harsh environments where dust, fog, rain, snow or vibration can cause a high reduction of signal.

Using “Xenon Flash” technology, the SafEye range is resistant to false alarms which can be caused by a partial blockage. Other common causes include extreme weather conditions and direct or reflected sunlight, flame or other radiation sources such as flare stacks, arc welding or lightning.

Crowcon SafEye Quasar 900 Gas Detectors

Features

Specially designed Duct Open Path Gas Detectors designed and widely used to monitor the ingress of hazardous flammable gas concentrations into the air intakes of turbine engines and HVAC air ducts.

- Designed to meet SIL2 per IEC61508 and FM performance approved per FM6325 and tested per EN60079-29-4

- The main stainless steel enclosure is Ex d (flameproof) with an integral, segregated, Ex e (increased safety) terminal section

- Includes heated windows to eliminate condensation and icing

- An intrinsically safe (I.S.) communicator can be connected for diagnostic and maintenance purposes

- HART capability for digital communication

- T&D also stock & ship products from stock suitable for frost protection, hot water, ramp heating and roof & gutter heating

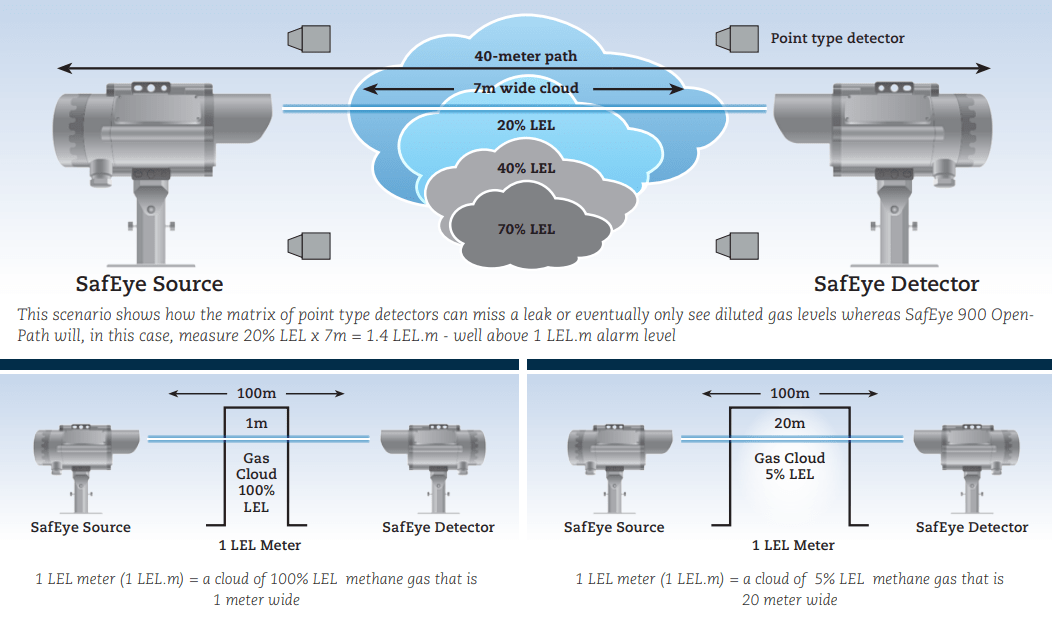

Detecting Gas | Gas leak can be picked up by Open Path Detectors which point detectors miss

SafEye Quasar 900 Gas Detector

Specification

Electrical Specifications

- Power Supply: 24VDC nominal (18-32 VDC)

- Power Consumption (peak includes heated optics): Detector: 250mA (300mA Peak) | Source: 250mA (300mA Peak)

- Warm Up Time: 30 sec for transmitter and receiver

- Electrical Connection (specify): 2 x 3/4″ – 14NPT conduits or 2 x M25 x 1.5mm ISO

- Electrical Input Protection: per MIL-STD-1275B

- Electromagnetic Compatibility: EMI/RFI protected per EN50270

General Specifications

| Crowcon SafEye Quasar Model |

901 | 902 | 903 | 904 | |

| Gas Detecting Range | Feet Metres |

23-66 7-20 |

50-132 15-40 |

115-330 35-100 |

265-660 80-200 |

| Receiver |

QR-X-11X | QR-X-11X | QR-X-11X | QR-X-11X | |

| Transmitter | QR-X-11X | QT-X-21X | QT-X-31X | QT-X-41X | |

| Detected Gas | C1 – C8 | ||||

| Response Time | 3 seconds | ||||

| Immunity to False Alarm | Not influenced by solar radiation, hydrocarbon flames and other external IR radiation sources. | ||||

| Sensitivity Range | 0-5 LEL.m methane and propane 0-8 LEL.m ethylene |

||||

| Spectral Response | 2.0 – 3.0µm | ||||

| Displacement/Misalignment Tolerance | ±0.5° | ||||

| Drift | ±7.5% of the reading or ±4% of the full scale (whichever is greater) | ||||

| Minimum Detectable Level | 0.15 LEL.m | ||||

| Temperature Range | –67°F (–55°C) to 149°F (65°C) | ||||

| Humidity | Up to 95% non-condensing (withstands up to 100% RH for short periods) | ||||

| Heated Optics | To eliminate condensation and icing on the window | ||||

| Warranty | Safety system – 3 years Flash source bulb – 10 years |

||||

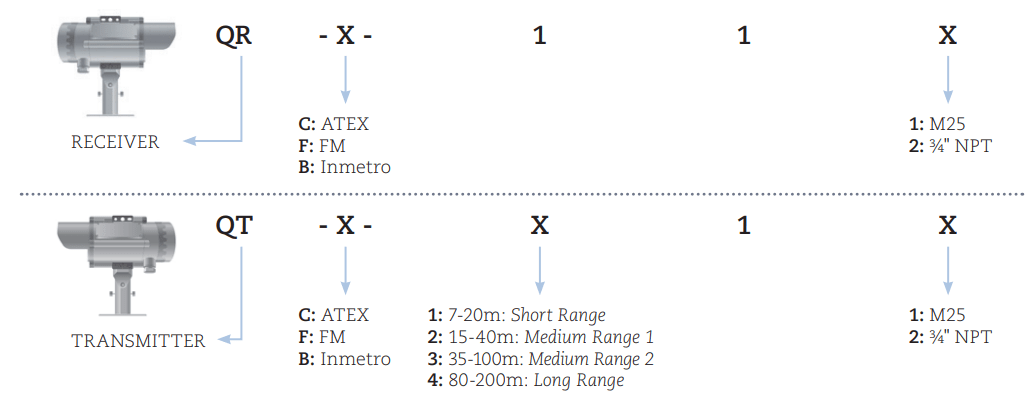

Order code for specific requirements | Give T&D a call for help & advice on selecting the correct gas detector for your application.

Mechanical Specifications

| Hazardous Area Approvals | ATEX/IECEx Ex d e ib [ib Gb] IIB + H2 T4 Gb Ex tb IIIC T135°C Db The detector or source units have a combination of approvals. Each is a single enclosure (Ex d) with integral, segregated rear terminal section (Ex e) and intrinsically safe (Ex ia) data-port for external in-situ connection to Hand-Held Diagnostic unit. FM/FMC Class I Div 1 Groups B, C and D Class II,III Div 1 Groups E, F and G Inmetro Ex d e ib [ib Gb] IIB+H2 T4 Gb |

| Performance | Approved per FM6325 and tested by FM per EN60079-29-4 |

| Reliability | SIL2 per IEC61508 (TUV) |

| Enclosure | The source and detector housings are stainless steel 316L with electro polish finish. The circuit boards are conformal coated and protected from mechanical vibrations. The tilt mount is also stainless steel 316L. |

| Dimensions | Detector/Source – 10.5 x 5.1 x 5.1 inch (267 x 130 x 130mm) Tilt Mount – 4.7 x 4.7 x 5.5 inch (120 x 120 x 158mm) |

| Weight | Detector/Source 11lb (5kg) Tilt Mount 4.2lb (1.9kg) |

| Water & Dust Tight | IP66 and IP68 NEMA 250 6P |

| Environmental | Meets MIL-STD-810C for Humidity, Salt and Fog, Vibration, Mechanical Shock, High and Low Temperature |

Hazardous Area Equipment

Visit hazardous area gas detectors for explosion and flameproof gas monitoring and detection instruments with certification for potentially explosive atmospheres, including Zone 1 and Zone 2 (according to ATEX and IECEx) and Class/Division categories (according to North American standards).

T&D provide competitive prices and delivery for all Crowcon Gas Detectors, including the Crowcon Open Path Gas Detectors.

:arrow: Did you know? Crowcon fixed gas detectors protect plant; portable gas detectors protect people.

T&D Sales Team are Certificated by Crowcon to support the specification and supply of their flammable and toxic gas detectors. Additionally, T&D are CompEx Certificated and competent in understanding hazardous area classifications and site requirements for the sale of explosion and flameproof equipment.

Flame, Heat, Gas Detectors & Detection Systems

![]()

Hazardous area industries including offshore oil/gas platforms and FPSOs, onshore oil refineries, processing plants, pipelines, storage farms and LPG/LNG plants all utilise or produce a wide range of hazardous flammable liquids and gases that can be detected using correctly specified flame and gas detectors.

Detecting toxic and flammable gases requires the detectors to be classified and certified according to the specific IECEx or ATEX standard – we distribute flame and fire detectors manufactured by Spectrex to operate in the harshest environmental conditions including self-contained stand-alone devices designed for direct connection to control and alarm systems or automatic fire extinguishing systems.

Our range of Hazardous Area Fire & Gas Detection System products also includes Explosion Proof Warning Systems & Hazardous Area Lighting – comprehensive range of intrinsically safe, flameproof and explosion proof alarm sounders, sirens, bells and horns, loudspeakers and beacons.

♦ LV Power Products | Junction Boxes & Enclosures ATEX | Plugs ATEX | Control Stations ATEX | Isolators ATEX

Thorne & Derrick | Detecting Flame | Heat | Gas