Detecting Gas | SafEye Xenon 700 Fixed Gas Detectors

Crowcon Safeye Xenon 700 Fixed Gas Detector

SafEye Xenon 700

Detecting Gas

Open Path Gas Detection System | Continuous Monitoring for Combustible Hydrocarbon Gases

The SafEye Xenon 700, manufactured by Crowcon, is an open path fixed gas detection system. This gas detector integrates well-proven and superior Xenon Flash technology which has an excellent operational record in many installations ranging from the deserts of Africa and Asia and the very hot and humid Far East, to the wet and cold North Sea and the dry and cold regions of Alaska.

The Crowcon SafEye 700 Optical Open Path (Line-of-Sight) Gas Detection System employs “spectral fingerprint” analysis of the atmosphere using the Differential Optical Absorption Spectroscopy (DOAS) technique in a unique (patented) method. Using superior “Xenon Flash” technology the SafEye range is immune to false alarms caused by partial blockage and extreme weather conditions (fog, rain or snow) and direct or reflected sunlight, flame or other black body radiation sources.

➡ Differential Optical Absorption Spectroscopy (DOAS) is used to measure concentrations of trace gases.

Detecting Gas in Hazardous AreasCrowcon SafEye Xenon 700 Gas Detectors

Features

- Reliable detection of gas leaks including a wide range of gaseous hydrocarbons, such as: Alkanes, Alkenes (C1-C8), Alcohols, LNG, LPG, Ethylene, etc.

- One person can simply and easily align and commission SafEye with separate horizontal and vertical adjustments.

- Direct reading, high sensitivity and fast response (3 sec) ensures instant action and maximum safety.

- Provides relatively wide angle of view, better than 1˚, to withstand vibration, mechanical shock and displacements.

- Rugged Structure – Stainless steel 316L, IP66/67, Zone 1 ready design.

- Electro-optical system, not affected by chemicals

- Standard 4-20 mA output with a new mode (3 mA) “Maintenance call” or RS-485, Modbus compatible output to allow networking (up to 256 detectors) to a central monitoring / PC system. This feature also enables easy maintenance, local and remote diagnostic tools.

- Less units needed for protection compared with point type detection. One system can replace from 5 to 20 point gas detectors. Low cost of ownership, much lower installation cost!

- Thousands of first generation Flash Type SafEye are installed on offshore platforms, FPSO’s, refineries, and other onshore applications operated by British Petroleum (BP), Shell, ExxonMobil, Statoil, and others.

- Well-proven in harsh environments (rain, snow, fog, hot and humid weather), up to 90% beam blockage, an excellent operational record in many installations worldwide.

– Heated Optics on the source and detector increase the temperature of the optical surface to reduce icing, condensation and snow.

– Resilient and excellent performance withstanding extreme vibrations, displacement and shock.

– Solar blind and immune to false alarms from industrial environments - T&D also stock & ship products from stock suitable for frost protection, hot water, ramp heating and roof & gutter heating

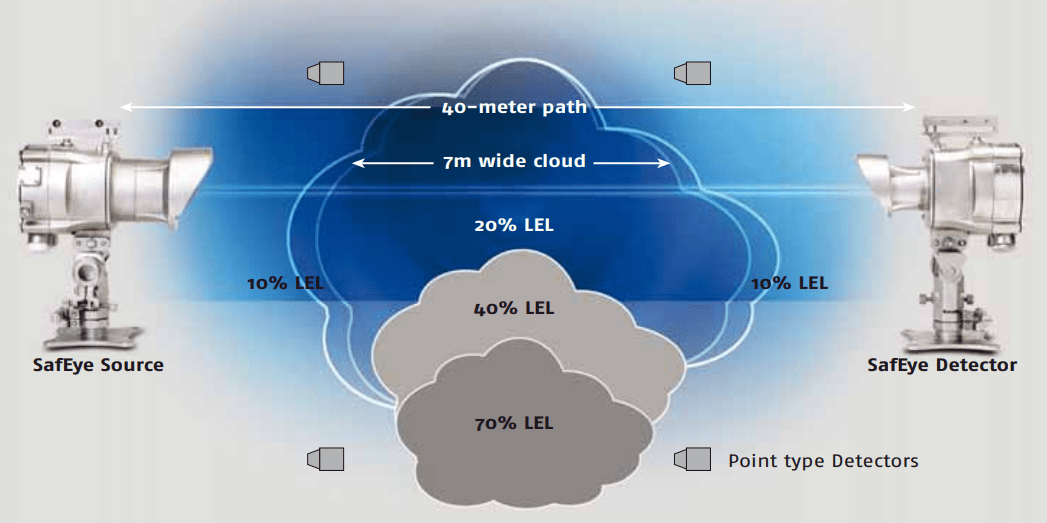

This scenario shows how the matrix of point type detectors can miss a leak or eventually only see diluted gas levels whereas SafEye 700 Open-Path will, in this case, measure 20% LEL x 7 m = 1.4 LEL.m – well above 1 LEL.m alarm level

Not all gas clouds are hazardous

Only if a flammable gas cloud or plume is wide enough to allow flame acceleration to speeds greater than 100 m/sec does it become a significant threat.

- Just as an athlete performing the long jump needs a run-up distance, so too a flame front needs distance to reach the velocities which cause the damaging effects of over-pressure, pressure pulse and windage.

- The generally accepted quantity of gas that creates the potential to cause consequential damage if ignited is a cloud of the size 5 m diameter a stoichiometric concentration (about 200% LEL).

- To provide a safety margin, this concentration is halved to 100% LEL. Thus an open path beam traversing this cloud would indicate 5 LEL.m.

- Location of the SafEye 700 Open-Path Gas Detector is less important than with point type detectors as it provides a warning alarm from a diluted gas cloud and does not need to be close to the leakage source.

- Point type detectors measure gas at their location in terms of % LEL, whereas open-path gas detectors measure the amount of gas anywhere along the length of the path, in terms of the integral of concentration and length (LEL x meters).

SafEye Xenon 700 Gas Detector

Specification

Crowcon SafEye 700 consists of an advanced Xenon Flash infrared transmitter (source) and an infrared detector (receiver), separated over a line of sight from 13 ft. (4 m) up to 460 ft. (140 m) to detect flammable gas presence, even when challenged by extremely harsh environments where dust, fog, rain, snow or vibration can cause a high reduction of signal.

The SafEye Xenon 700 analyses atmospheric absorption at three selected spectral bands, two in a region where the target gas absorbs and one where it does not absorb. The ratio between these absorption lines can provide accurate information of the gas concentration along an optical path. The reference sensor detects beam blockage, compensates for changing humidity and detects failed light source or dirty optics.

Crowcon Safeye’s source and detector units are both housed in low profile, rugged, stainless steel, ATEX approved enclosures.

The main enclosure is EEx d flameproof with an integral, segregated, EEx e increased safety terminal section.

The hand-held communication unit can be connected in-situ via the intrinsically safe approved (EEx ia) data port on the detector. SafEye 700 includes heated optics on the transmitter (source) and receiver (detector) to address icing, condensation and snow.

Electrical Specifications

- Power Supply: 24VDC nominal (18-32 VDC)

- Power Consumption (peak includes heated optics): Detector: 150mA (300mA Peak) | Source: 100mA (300mA Peak)

- Electrical Connection (specify): 2 x 3/4″ – 14NPT conduits or 2 x M25 x 1.5mm ISO

- Electrical Input Protection: per MIL-STD-1275B

- Electromagnetic Compatibility: EMI/RFI protected CE Marked

General Specifications

| Crowcon SafEye Xenon Model | 701 | 702 | 703 | 721 | 722 | 723 |

| Gas Detecting Range | 13 – 66ft 4 – 20m |

50 – 230ft 15 – 70m |

165-460ft 50 – 140m |

13 – 66ft 4 – 20m |

50 – 230ft 15 – 70m |

165 – 460ft 50 – 140m |

| Detected Gas | C1-C8 | Ethylene | ||||

| Response Time | T90 – 3 seconds | |||||

| Immunity to False Alarm | Not influenced by solar radiation, hydrocarbon flames and other external IR radiation sources | |||||

| Spectral Response | 2.0 – 4.0 μm | |||||

| Sensitivity Range | 0 – 5 LEL.m (optional 0 – 2 LEL.m) | |||||

| Displacement/Misalignment Tolerance | ±1˚ | |||||

| Drift | Long term ±5% of full scale | |||||

| Temperature Range | -40˚F (-40˚C) to 131˚F (55˚C) | |||||

| Warranty | SafEye system – 3 years Flash source bulb – 10 years |

|||||

Mechanical Specifications

| Hazardous Area Approvals | ATEX EX II 2(1) GD, EExde ia [ia] IIC T5 (55˚C). The detector or source units have a combination of approvals. Each is a single enclosure (EEx d) with integral, segregated rear terminal section (EEx e) and intrinsically safe (EEx ia) data-port for external in-situ connection to Hand-Held Diagnostic unit IECEx Ex d e ia [ia] IIC T5 (Ta=-40°C to +55°C or -40°C to +70°C) |

| Enclosure | The source and detector housings are stainless steel 316L with electro polish finish. The circuit boards are conformal coated and protected from mechanical vibrations. The tilt mount is also stainless steel 316L. |

| Dimensions | Detector – 8.2 x 5.7 x 6 inch (210 x 145 x 154 mm) Source – 10 x 5.3 x 6.9 inch (255 x 135 x 175 mm) Tilt Mount – 4.7 x 4.7 x 5.5 inch (120 x 120 x 158mm) |

| Weight | Detector – 9.2 Lb (4.2 Kg.) Source – 10.1 Lb (4.6 Kg) Tilt Mount – 4.2 Lb (1.9 Kg) |

| Water & Dust Tight | IP66 and IP67 NEMA 250 6P |

| Environmental | Meets MIL-STD-810C for Humidity, Salt and Fog, Vibration, Mechanical Shock, High and Low Temperature |

Hazardous Area Equipment

Visit hazardous area gas detectors for explosion and flameproof gas monitoring and detection instruments with certification for potentially explosive atmospheres, including Zone 1 and Zone 2 (according to ATEX and IECEx) and Class/Division categories (according to North American standards).

T&D provide competitive prices and delivery for all Crowcon Gas Detectors, including the Crowcon Open Path Gas Detectors.

:arrow: Did you know? Crowcon fixed gas detectors protect plant; portable gas detectors protect people.

T&D Sales Team are Certificated by Crowcon to support the specification and supply of their flammable and toxic gas detectors. Additionally, T&D are CompEx Certificated and competent in understanding hazardous area classifications and site requirements for the sale of explosion and flameproof equipment.

Flame, Heat, Gas Detectors & Detection Systems

![]()

Hazardous area industries including offshore oil/gas platforms and FPSOs, onshore oil refineries, processing plants, pipelines, storage farms and LPG/LNG plants all utilise or produce a wide range of hazardous flammable liquids and gases that can be detected using correctly specified flame and gas detectors.

Detecting toxic and flammable gases requires the detectors to be classified and certified according to the specific IECEx or ATEX standard – we distribute flame and fire detectors manufactured by Spectrex to operate in the harshest environmental conditions including self-contained stand-alone devices designed for direct connection to control and alarm systems or automatic fire extinguishing systems.

Our range of Hazardous Area Fire & Gas Detection System products also includes Explosion Proof Warning Systems & Hazardous Area Lighting – comprehensive range of intrinsically safe, flameproof and explosion proof alarm sounders, sirens, bells and horns, loudspeakers and beacons.

♦ LV Power Products | Junction Boxes & Enclosures ATEX | Plugs ATEX | Control Stations ATEX | Isolators ATEX

Thorne & Derrick | Detecting Flame | Heat | Gas