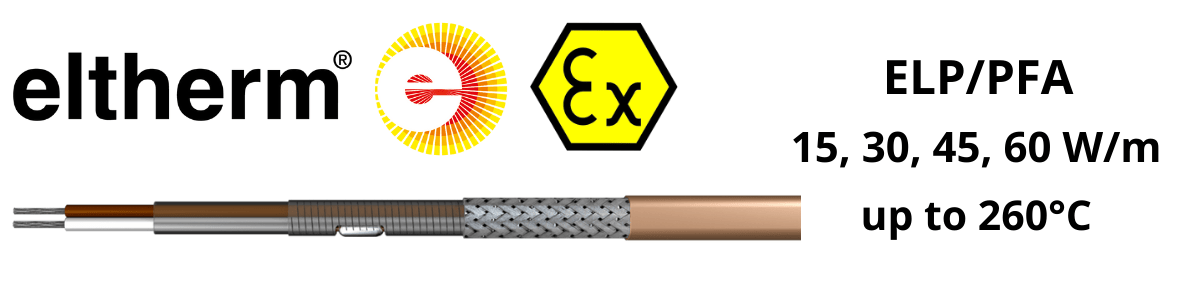

Constant Wattage Heat Tracing | Eltherm ELP/PFA ATEX Heat Tracing Cable up to 260°C

Thorne & Derrick | Distributed from Stock | UK & Export Sales | Customer Service Excellence | ATEX Compliant Solutions

Constant Wattage heat tracing

ATEX Heat Tracing Cable | Eltherm ELP/PFA

Eltherm ELP/PFA constant wattage heat tracing cables provide process temperature maintenance and frost protection to pipework, instrument lines, tanks and drums up to 260° Celsius – with IECEx and ATEX Certification Eltherm ELP/PFA heat tracing are suitable for Zone 1 and Zone 2 hazardous areas.

These parallel trace heaters offer tremendous flexibility in use, as they can easily be cut to the required length off the roll, with the assurance of constant power output. There is no need for a connecting cable and input can be unilateral. The constant wattage trace heating cable is quick and easy to assemble and therefore saves time and reduces operating costs.

Since output of up to 60 W/m is possible for lengths laid to piping, ELP/FA parallel trace heating cables are particularly suitable for piping with high output requirements such as in industrial process technology. Industries and applications were the heat tracing cables are used are as follows:

- Valves, pumps

- Pipelines

- Food Processing Industry

- Paper Industry

- Building construction

Eltherm ELP/PFA heat tracing Cables – SPECIFICATION

Eltherm ELP/PFA Heater Cable wattages per metre – 15, 30, 45 and 60 watts.

- Nominal Supply Voltage : 230VAC up to 277 VAC*

- Nominal Temperature : 260ºC

- Minimum Installation & Start Up Temperature : -60° Celsius

- Minimum Heater Cable Bend Radius : 25mm

- Insulation: PFA

- Constant Wattage Heater Cable Outer Jacket: PFA

- Protective Braid: Nickel-plated Copper

- Bus Wire Cross Section: 2 x 1.5mm² (2 x 2mm² also available)

- Moisture Proof: Yes

- Manufactured According To: DIN VDE 0721-52, EN 62395-1; 2007-05

* 277 VAC operation only approved for ELP/PFA 15W/m, 30 W/m and 45 W/m!

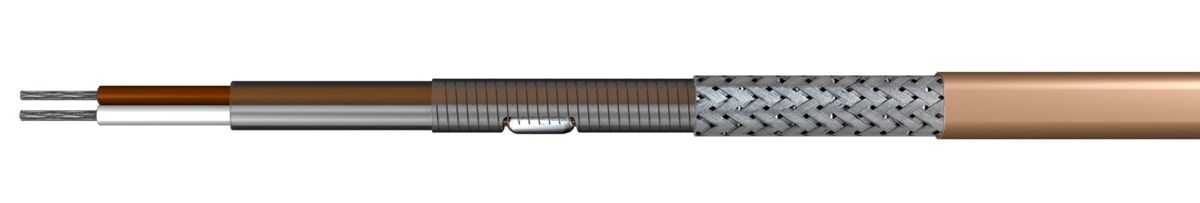

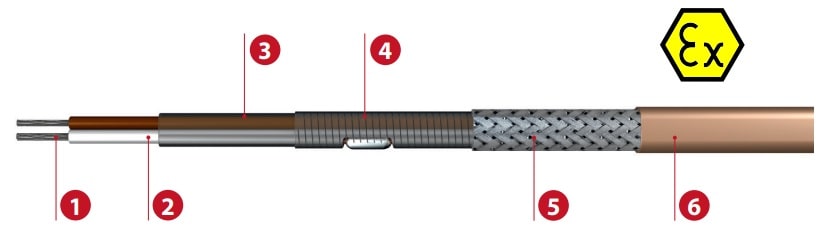

- Bus wire: Copper

- 1st insulation: Fluoropolymer

- Heating conductor: Heating conductor alloy

- 2nd insulation: Fluoropolymer

- Protective braid: Copper, nickel-plated

- Outer jacket: Fluoropolymer

Hazardous Area Classifications

![]() Heat Tracing Classification:

Heat Tracing Classification:

- II 2G Ex 60079-30-1 IIC Gb

- II 2D Ex 60079-30-1 IIIC Db

![]() System Classification:

System Classification:

- II 2G Ex 60079-30-1 IIC T6..T2 Gb

- II 2D Ex 60079-30-1 IIIC Txx°C Db

![]()

Hazardous Area Certification:

- IECEx EPS 12.0009 U

- IECEx EPS 21.0062 X

- EPS 12 ATEX 1438 U

- EPS 21 ATEX 1198 X

Temperature Class: T6

Eltherm ELP/PFA Benefits

- Single end power input

- Trace heating cable can be cut off the roll

- Constant power output per meter

- Long life cycle

- Laying without exact measuring possible

- High chemical resistance

- UV resistance

- Moisture proof

The ELP/PFA is guaranteed a long life by the fluoropolymer’s high degree of chemical resistance and its very temperature-resistant outer layer.

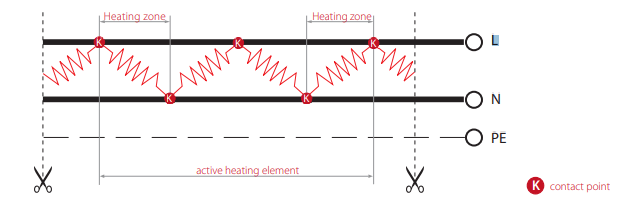

Constant wattage heating cables such as the ELP/PFA consist of a succession of heating zones (length = contact spacing) and can be cut to length in sections of the contact distance to the required length – when cutting heater cables into lengths, the heating circuit is interrupted up to the next contact point and this non-active part can be used as a cold lead.

heat tracing Cable Selection Table – Eltherm ELP/PFA

Contact T&D for technical guidance, heat loss calculations for pipework systems and optimum specification of the correct trace heater cable for your application.

| Eltherm ELP/PFA Heater Cable | Nominal Output | Maintain Temperature * max. |

Dimensions (mm) | Contact Spacing (m) | Weight 1.5mm² [mm] |

Cable Application |

| ELP/PFA 15 BOT | 15 w/m | 200ºC | 8.0 x 5.5 | 1.0 | 120 | Frost Protection & Process Heating |

| ELP/PFA 30 BOT | 30 w/m | 200ºC | 8.0 x 5.5 | 1.0 | 120 | Frost Protection & Process Heating |

| ELP/PFA 45 BOT | 45 w/m | 200ºC | 8.0 x 5.5 | 1.0 | 120 | Frost Protection & Process Heating |

| ELP/PFA 60 BOT | 60 w/m | 180ºC | 8.0 x 5.5 | 1.0 | 120 | Frost Protection & Process Heating |

* The maximum maintain temperature depends on the respective installation situation and must be considered on a case-to-case basis.

How Eltherm ELP/PFA Heater Cables Function

ELP/PFA Heating circuit length

| Heat Tracing Cable Type | Power [W/m] | Length @ start up temp. [m] |

| ELP/PFA 15 BOT | 15.0 | 184.0 |

| ELP/PFA 30 BOT | 30.0 | 100.0 |

| ELP/PFA 45 BOT | 45.0 | 66.0 |

| ELP/PFA 60 BOT | 60.0 | 50.0 |

Heating circuit length factor 230 V vs. 277 V = 0,83

Note:

Heating circuit lengths ELP/PFA on the following conditions:

- 16 A circuit breaker, 80 % utilisation, start up temp. +10°C

- Max. 10% voltage drop

- Power connection to one (1) heater end

Greater lengths are possible with higher rated circuit breakers, please contact T&D

Cables shall neither intersect nor contact

Provide protection by means of circuit breaker RCD 30 mA

Please observe the standards: IEC 62395-2, EN 60519-10, EN 62395-2

Bespoke Heated Hose Designs | 40+ Years Experience from Process Heating Specialists | CONTACT US