Fisher Baumann 51000 Low Flow Valve – Stem Sliding Valves

Fisher Baumann 51000 Low Flow Valve – Stem Sliding Valves

Fisher Baumann 51000 Low Flow Valve is part of the sliding stem valve range that is suitable for demanding low-flow, high-pressure control applications often found in laboratories and pilot plants.

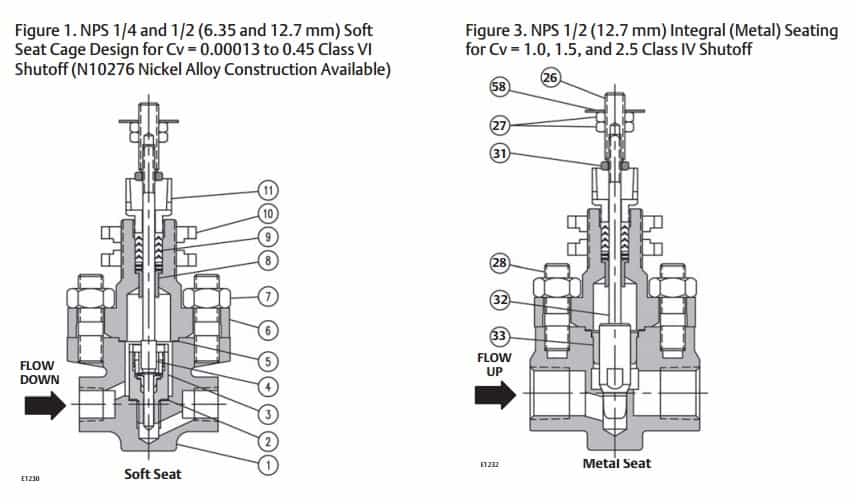

NPS 1/4 or 1/2 valve assemblies of the Baumann 51000 are standard in either cast stainless steel or N10276 nickel alloy

The design of the 51000 low flow valve is ideal for small areas where flexibility is crucial and is often referred to as a miniature valve.

Fisher Baumann 51000 Low Flow Valve

Product Features

- Compact Size

- Suitable for sticky fluids and corrosive atmospheres

- Quick Trim Change Out – Matched trims not required

- Investment cast stainless steel body in 1/4 and 1/2 inch sizes or barstock N10276 Nickel Alloy. Other alloys available.

- Class VI shutoff with soft seat available. Up to 3000 psig (207 barg) at 1000F (370C)

- Rugged bolted bonnet design

- Wide flow capacity range. Maximum rated Cv ranges from 0.00013 to 2.5 (0.0002 to 2.16 Kv)

- Corrosion resistant actuator

- Available without positioner for fail open or fail close applications

FISHER BAUMANN 51000 LOW FLOW VALVE

PRODUCT Specification

| Sizes | NPS 1/4, 1/2 |

| Connections | NPT threaded or proprietary fittings |

| Body Material | 316 SS or N10276 Nickel Alloy Options |

| Valve Body Rating | 3000 psi CWP |

| Trim Material | S21800 SST or N10276 Nickel Alloy |

| Trim Characteristic | Modified Equal % |

| Seat Leakage | ANSI/FCI 70-2 Class IV or VI |

| Cv Ratings | 0.00013 to 2.5 |

| Bonnet Type | Standard bolted |

| Packing Material | PTFE V-ring |

| Temperature Range | -29ºC to 177ºC (-20ºF to 350ºF) |

Fisher Baumann 51000 Low Flow Valve – Valve Body

FISHER BAUMANN 51000 LOW FLOW VALVE

Materials of construction

| Key No | Description | Material |

| 1 | Valve Body, NPS 1/4 and NPS 1/2 | ASTM A351 CF8M or ASTM B575 N10276, 35 HRC Max |

| 2 | Seat Cage Gasket | Reinforced Graphite |

| 3 | Figure 1 ONLY! Soft Seat Cage Assy, (Cv’s 0.00013 to 0.45), (Kv’s 0.00011 to 0.39) | See figure 2, table 1 see data sheet |

| Seat, Body (Integral Seat) (Cv’s 1.0, 1.5, 2.5); (Kv’s 0.86, 1.29, 2.16) | ASTM A351 CF8M or ASTM B575 N10276, 35 HRC Max | |

| 4 | Plug/Stem (Cv’s 0.00013 – 0.45); (Kv’s 0.00011 to 0.39) | ASTM A479 S21800 Annealed or ASTM B574 N10276, 35 HRC Max |

| 5 | Bonnet Gasket | Flexible Graphite and Polymer Composite |

| 6 | Bonnet | ASTM A351 CF8M or ASTM B574 N10276, 35 HRC Max |

| 7 | Hex Nuts | 18-8 Stainless Steel |

| 8 | Stem Guide | ASTM A582 S30300 Condition A or Carbon Fiber-Filled Thermoplastic Fluoropolymer |

| 9 | V-Ring Packing Kit | PTFE (Polytetrafluoroethylene) & S30400 & S30100 |

| 10 | Clamp Nut | ASTM A240 S30400 |

| 11 | Packing Follower Nut | ASTM A582 S30300 Condition A or ASTM B574 N10276, 35 HRC Max |

| 26 | Stem Adapter, Baumann 16 Actuator | 18-8 Stainless Steel |

| 27 | Hex Jam Nut, Baumann 16 Actuator | 18-8 Stainless Steel |

| 28 | Body Studs | S30400 ASTM A193, B8 Class 1 |

| 31 | Stem Adapter Nut | 18-8 Stainless Steel |

| 32 | Plug and Stem S/A (for metal seated plugs) Integral Seat, Cv’s 1.0, 1.5, & 2.5; (Kv’s 0.86, 1.29, 2.16) | ASTM A276 S31600 Condition A or ASTM B574 N10276, 35 HRC Max |

| 33 | Plug Guide | ASTM A479 S21800 Annealed or Carbon Fiber-Filled Thermoplastic Fluoropolymer |

| 34 | Flange, Bonnet | ASTM A743 CF8 |

| 35 | Travel Indicator Disc, Baumann 16 Actuator | 18-8 Stainless Stee |

See how Fisher Control Valves provide safe, efficient and intuitive flow control.

Fisher Rotary Valves: Flow Control For Power, Oil, Gas & Refining Pipelines

➡ Did you know? Fisher Control Valves are approved, certified and classified to international standards including ASME, CSA, IEC, NACE, FDA & NFPA. Should you require assistance with valve specification for explosion-proof or intrinsically safe applications in the hazardous area industries, please contact T&D.

Fisher Control Valves – Approvals