Fisher HP & EH High Pressure Globe Valves – Sliding Stem Valves

Fisher HP & EH High Pressure Globe Valves – Sliding Stem Valves

Fisher HP & EH High Pressure Globe Valves are part of the sliding stem valve range for high-pressure steam, hydrocarbon, or general service, including cavitating liquids or noisy gases and vapours. The Fisher HP & EH are suitable for temperatures to 537ºC and pressures to PN160 (CL2500) and sizes from DN25 through DN100 DIN and NPS 1 through 20.

HP & EH valves have ENVIRO-SEAL™ and HIGH-SEAL packing systems to help ensure compliance with environmental emissions requirements. FIELDVUE™ digital valve controllers.

Fisher HP & EH High Pressure Globe Valve

Product Features

- Valve Plug Stability— Rugged cage guiding provides increased valve plug stability, which reduces vibration and mechanical noise.

- Full Pressure Drop Capability—Rugged HP and HPA valves have readily available trims capable of attaining full pressure drops.

- Spiral-Wound Gaskets for Excellent Sealing Under All Service Conditions—Premium materials are used in the construction of spiral-wound gaskets for HP Series valves. These premium materials, which make up the standard spiral-wound gaskets, are N06600 (alloy 600)/graphite or N07750 (alloy X750)/graphite.

- Compliance with the Clean Air Act—Optional ENVIRO-SEAL™ packing systems provide an improved stem seal to help prevent the loss of valuable process fluid or emission of hazardous process fluid. The ENVIRO-SEAL packing systems feature PTFE or graphite ULF.

- Piping Economy—The availability of expanded end connections on NPS 4 and 6 HP valves may eliminate the need for line swages while accommodating oversized piping arrangements.

- Quick Change Trim—Maintenance is simple and can easily be performed using common tools. Trim components can be quickly removed and changed with no need for special tools.

- Standard Hard Trim Materials—The cage, valve plug, and other trim parts are manufactured from hardened materials. This standard feature provides excellent wear resistance.

- Control of Low Flow Rates/Tight Shutoff—Micro-Flute and Micro-Form valve plugs provide superb rangeability in high-pressure, low-flow applications, while maintaining tight shutoff. A choice of several restricted port diameters helps to match valve body capacity to required flow, to provide necessary control with full travel, and to prevent throttling near the seat

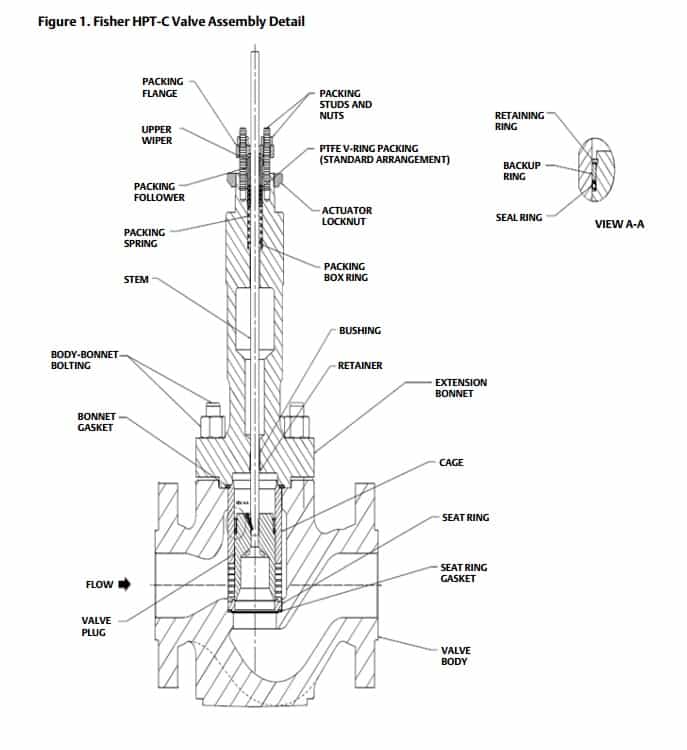

Fisher HPT High Pressure Globe Valve – Sliding Stem Valves – Assembly Detail

FISHER HP & EH HIGH PRESSURE GLOBE VALVE

PRODUCT Specification

| Fisher HP | Fisher EH | |

| Available Configurations and Valve Sizes | HPT-C: Single-port, globe-style control valve with cage-guiding, balanced valve plug, and push-down-to-close valve plug action (figure 1) HPS-C: Single-port, globe-style control valve with cage-guiding, unbalanced valve plug, and push-down-to-close valve plug action | Common Characteristics: EH valves are single-port, high-pressure, globe-style valves with metal seats, cage guiding, and push- down- to- close valve plug action. EHA valves are angle versions of EH valves |

| Valve Sizes/Types | HPS-C: NPS 1 to 3 (CL900 and CL1500) NPS 1 to 2 (CL2500) HPT-C: NPS 4 and 6 (CL900 and CL1500) E | Globe Valves & Angle Valves |

| End Connections Styles | CL900, 1500, and 2500 raised-face and ring-type-joint flanges per ASME B16.5. Buttweld end connection per ASME B16.25. PN160 and PN250 flanges per EN1092-1. | Buttwelding Ends (BWE): See table 6 for all available ASME B16.25 schedules that are compatible with ASME B16.34 pressure/temperature ratings Flanged Ends: CL900, CL1500, or CL2500 ring-type joint (RTJ) or raised-face (RF) flanges according to ASME B16.5. Flanged ends for EHA valves are available in CL900 and 1500 only Soc |

| Maximum Inlet Pressure | Consistent with CL900, 1500, and 2500 pressure/temperature ratings per ASME B16.34 | Consistent with applicable CL900, 1500, or 2500 pressure/temperature ratings (for EH valves) according to ASME B16.34 unless limited by individual temperature limits shown in the Material Temperature Capabilities In addition, both steel EH and EHA valves with BWE connections have increased pressure/ temperature rating |

| Maximum Pressure Drop | Consistent with CL900, 1500, and 2500 pressure/temperature ratings per ASME B16.34 | Valve With Standard Cage: See figures 20, 21, and 22 Valve With Cavitrol™ III Cage: 149 bar (2160 psi) for two-stage cage and 207 bar (3000 psi) for three-stage cage |

| Shutoff Classifications per ANSI/FCI 70-2 and IEC 60534-4 | HPT-C and HPS-C Metal Seat: Class IV is standard Class V Air Test is optional (Test will be at 50 psid air)(2) Cryogenic Leak Test: Class C (optional) | For NPS 20 valves, one-half of Class IV leakage (0.005% of valve capacity at full travel) per ANSI/FCI 70-2 and IEC 60534-4 |

| Flow Characteristics | HPT-C and HPS-C Equal percentage, linear, modified equal percentage Fl | Standard Cage: Equal percentage, modified equal percentage, or linear Micro-Form Valve Plug (for EHS and EHAS only): Equal percentage or modified equal percentage. Micro-Flute Valve Plug (for EHS and EHAS only): Equal percentage or modified equal percentage. Micro-Flat Valve Plug (EHAS only): Linear Cavitrol III, Whisper Trim III, or WhisperFlo: Linear Special cages: Special characterized flow characteristic cages are available. Please |

| Flow Direction | HPT-C: Normally flow down for linear and equal percentage trims. Flow up for Whisper Trim™ HPS-C: Normally flow up | Standard Cage EHD: Normal flow down EHS: Normal flow up EHT: Normal flow down EHAD: Normal flow down EHAS: Normal flow up EHAT: Normal flow down Cavitrol III Cage: Flow down Whisper Trim III cage: Flow up WhisperFlo Trim: Flow up For NPS 20 Valves: Flow up through seat ring and out through cage openings (for standard and Whisper cages) |

| Construction Materials | Valve Body and Bonnet: CF8M Body-bonnet Bolting: Bonnet Bushing: S31600/filled PTFE Flat Sheet Gaskets: S31600/graphite Spiral Wound Gasket: N06600/graphite Packing Studs and Nuts: S31600 SST Seal Ring (HPT-C): UHMWPE with R30003 spring Back-Up Ring (HPT-C): S31600 (316 SST) Retaining Ring (HPT-C): S30200 (302 SST) Packing Follower, Lantern Ring, Packing Spring and Packing Box Ring: S31600 SST | All Except NPS 20 Valve Body and Bonnet: WCC steel, LCC steel, WC9 chrome-moly steel, C12A chrome-moly alloy, or CF8M (316 SST or 316H SST for service above 538C [1000F]) Trim: Trim material (See data sheet for NPS 20) |

| Material Temperature Capabilities | HPT-C: -198 to 66C (-325 to 150F) HPS-C: -198 to 316C (-325 to 600F) Bo | EHD/EHAD and EHS/EHAS: Up to 593C (1100F) unless limited by selection of standard trim materials Cavitrol III and Whisper Trim III trim materials, or other parts EHT/EHAT: Up to 316C (600F) unless limited by selection of standard trim materials, Cavitrol III and Whisper Trim III trim materials, or other parts Flow Chart |

| Packing Arrangements | Standard Material Single PTFE V-ring. See figures 1 and 2 Optional Material Double PTFE V-ring and Graphite ribbon/filament ENVIRO-SEAL™ Packing Systems Packing Material: PTFE V-ring and Graphite ULF. See | Single, double, and leakoff standard packing arrangements, or optional HIGH-SEAL packing systems; se |

| Options | HPT-C: Whisper Trim III and WhisperFlo™ trim for aerodynamic noise attenuation, and Cavitrol™ III cages for liquid cavitation protection are available. | Flat sheet seat ring gasket constructions(6), driver for removing and installing of seat ring retainer, Class V shutoff for EHT above 232C (450°F) to 316°C (600°F) by using PEEK anti-extrusion rings, Class V shutoff for EHD up to 593C (1100F) using C-seal trim or Bore Seal, lubricator/isolating valve for packing lubrication, and liner with integral seat ring (EHA Series valves only) Opt |

- See Data sheets for further details

See how Fisher Control Valves provide safe, efficient and intuitive flow control.

Fisher Rotary Valves: Flow Control For Power, Oil, Gas & Refining Pipelines

➡ Did you know? Fisher Control Valves are approved, certified and classified to international standards including ASME, CSA, IEC, NACE, FDA & NFPA. Should you require assistance with valve specification for explosion-proof or intrinsically safe applications in the hazardous area industries, please contact T&D.

Fisher Control Valves – Approvals