Zone 1 & Zone 2 Aluminium Enclosures & Junction Boxes – ATEX Hazardous Area

Zone 1 & Zone 2 Aluminium Enclosures & Junction Boxes – ATEX Hazardous Area

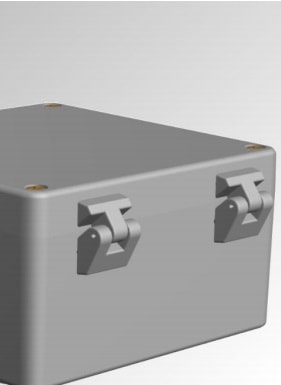

Abtech ZAG aluminium electrical enclosures and junction boxes are ATEX certified and suitable for Zone 1 and Zone 2 hazardous areas.

Abtech ZAG enclosures are available in 19 diffferent sizes manufactured from precision die cast in Al Si 12 grade (LM24) aluminium alloy – the ambient temperature of ZAG range is from -70°C to 130°C.

The Abtech ZAG aluminium range of hazardous area enclosures feature excellent ingress protection qualities meaning this enclosure has been tested and passed IP65/IP66/IP67.

Aluminium enclosures are hazardous area certified ATEX and IECEx Ex ‘e’ (Zone 1 & 2), Ex ‘nA’ (Zone 2) and Class 1, Div 2 (CSA, UL & FM).

Zone 1 & Zone 2 Hazardous area

Aluminium Enclosures & Junction Boxes

Abtech ZAG Features

Junction Boxes & Enclosures

- Wide Operating Temperature (- 65ºC to +150ºC) (-85°F to +302°F)

- Ingress Protection up to IP67

- Painted and Unpainted versions

- Impact Resistant > 7 Nm

- Corrosion Resistant

- Can be drilled and tapped to accommodate most thread forms (NPT for example)

- Certification for use in Zone 1 and 2

- UL, CSA, IEC Ex, ATEX, FM, InMetro and TR CU Approvals

- Ideal for Petrochemical and Marine applications

Zone 1

A hazardous area location according to ATEX in which an explosive atmosphere consisting of a mixture with air of flammable substances in the form of gas, vapour or mist is likely to occur in normal operation occasionally.

Zone 2

A hazardous area location according to ATEX in which an explosive atmosphere consisting of a mixture with air of flammable substances in the form of gas, vapour or mist is not likely to occur in normal operation but, if it does occur, persists for a short period only.

ATEX Explained

The ATEX Directive consists of two EU directives describing the type of equipment and hazardous area location within a potentially explosive atmosphere. ATEX originates its name from the French title of the 94/9/EC directive: Appareils destinés à être utilisés en ATmosphères EXplosibles.

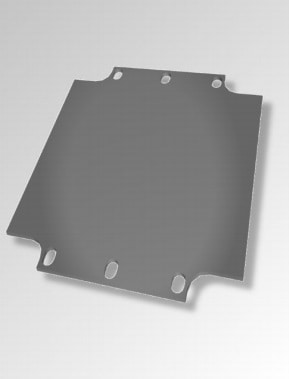

Cable entries can be drilled in the enclosure or junction box door, sides or via the cable gland plates – cable entries can also be drilled through the rear face of the stainless steel enclosure (EEx’e’ hazardous area versions).

The hazardous area enclosures include a hinged, lift-off door secured to the junction box using 4 captive stainless steel screws which also maintain the correct compression on the gasket.

Electrical Enclosure Junction Box Accessories

Unpainted (raw) finish |

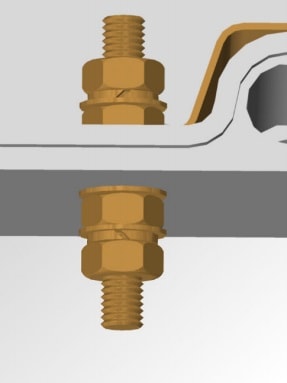

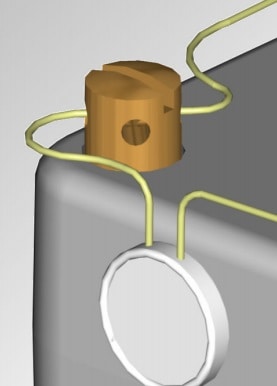

Earth Stud (either brass or stainless steel) |

Allen Head fixing screws (grade 316) |

Tamper-proof screws |

External hinges |

Component mounting plate |

External mounting feet (stainless steel 316) |

Internal Earthing bar (can be fitted with clamps) |

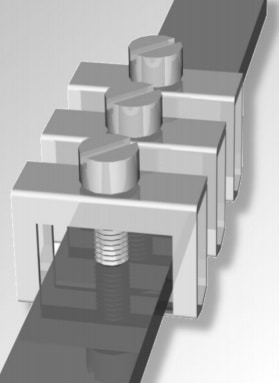

DIN standard mounting rail |

Hazardous Area Certification

Hazardous Area Enclosures: Intrinsically Safe Junction Boxes

Abtech ZAG enclosures are certified according to leading hazardous area classifications including:

- ATEX and IECEx:

– Ex ia (Zone 0) and Ex ta (Zone 20)

– Ex e Ex ib (Zone 1) and Ex tb (Zone 21)

– Ex nA (Zone 2) and Ex tc (Zone 22)

- CSA Ex e (Class 1, Zone 1)

- FM AEx e (Class 1, Zone 1)

- TYPE 4X (CSA, FM, UL)

- TR CU

T&D, The Explosive Atmosphere Experts, provide a single-source capability for the most extensive range of Electrical, Mechanical, Process & Instrumentation Equipment suitable for hazardous area locations.

- Zone 1 Hazardous Area Lighting

- Zone 2 Hazardous Area Lighting

- Enclosures, Motor Starters & Isolators

Abtech ZAG aluminium enclosures are certified according to international hazardous area classifications including UL, CSA, IEC Ex, ATEX, FM, InMetro and TR CU.

Abtech ZAG Junction Boxes Selection Table

If in doubt, please contact T&D for specification support and selection advice about hazardous area junction boxes and enclosures.

| Abtech Part Number | Width (mm) | Height (mm) | Depth (mm) | UP – Unpainted | EX – Ex Certified | AL – Alochromed | ES – Earth Stud | AS – Allen Head Fixing Screws | TP – Tamper Proof Screws | EH – External Hinges | MP – Component Mounting Plate | MF – External Mounting Feet | EB – Internal Earthing Bar | MR – DIN Standard Mounting Rail | RF – RFI Protection |

| ZAG1 | 50 | 45 | 30 | ♦ | ♦ | ♦ | ♦ | ♦ | |||||||

| ZAG2 | 58 | 64 | 34 | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | |||||

| ZAG3 | 98 | 64 | 34 | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | |||

| ZAG4 | 150 | 64 | 34 | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | |||

| ZAG5 | 75 | 80 | 57 | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | |

| ZAG6 | 125 | 80 | 57 | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | ||

| ZAG7 | 175 | 80 | 57 | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | |

| ZAG8 | 250 | 80 | 56 | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | |

| ZAG9 | 122 | 120 | 80 | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ |

| ZAG9/9 | 122 | 120 | 90 | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ |

| ZAG10 | 220 | 120 | 80 | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ |

| ZAG10/9 | 220 | 120 | 90 | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ |

| ZAG11 | 160 | 160 | 90 | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ |

| ZAG12 | 260 | 160 | 90 | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ |

| ZAG13 | 360 | 160 | 90 | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ |

| ZAG14 | 560 | 160 | 90 | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ |

| ZAG15 | 202 | 230 | 110 | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ |

| ZAG16 | 330 | 230 | 110 | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ |

| ZAG21 | 120 | 360 | 80 | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ |

Aluminium Enclosures

Abtech ZAG junction box features a unique labyrinth seal system that protects the inner seal from the external environment. Mounting holes although contained within the profile of the enclosure also sit outside of the seal.

Earthing

Abtech ZAG enclosures have fixtures that are manufactured from 316 grade stainless steel and standard earthing via an external/internal stainless steel stud.

With international hazardous area classifications, including ATEX, Abtech ZAG aluminium junction boxes and enclosures are suitable for onshore and offshore installation in both Zone 1 & Zone 2 hazardous area locations. T&D provide pre-assembled terminal enclosures for use as hazardous area lighting, power, heat tracing and instrument junction boxes with increased safety, intrinsically safe and flameproof explosion protection methods – we can custom supply high voltage enclosures for 3.3kV, 6.6kV, 11kV and 33kV networks.