ATEX Bespoke Fibre Optic Panels

ATEX Bespoke Fibre Optic Panels

ATEX Bespoke Fibre Optic Panels

Application – Hazardous Area

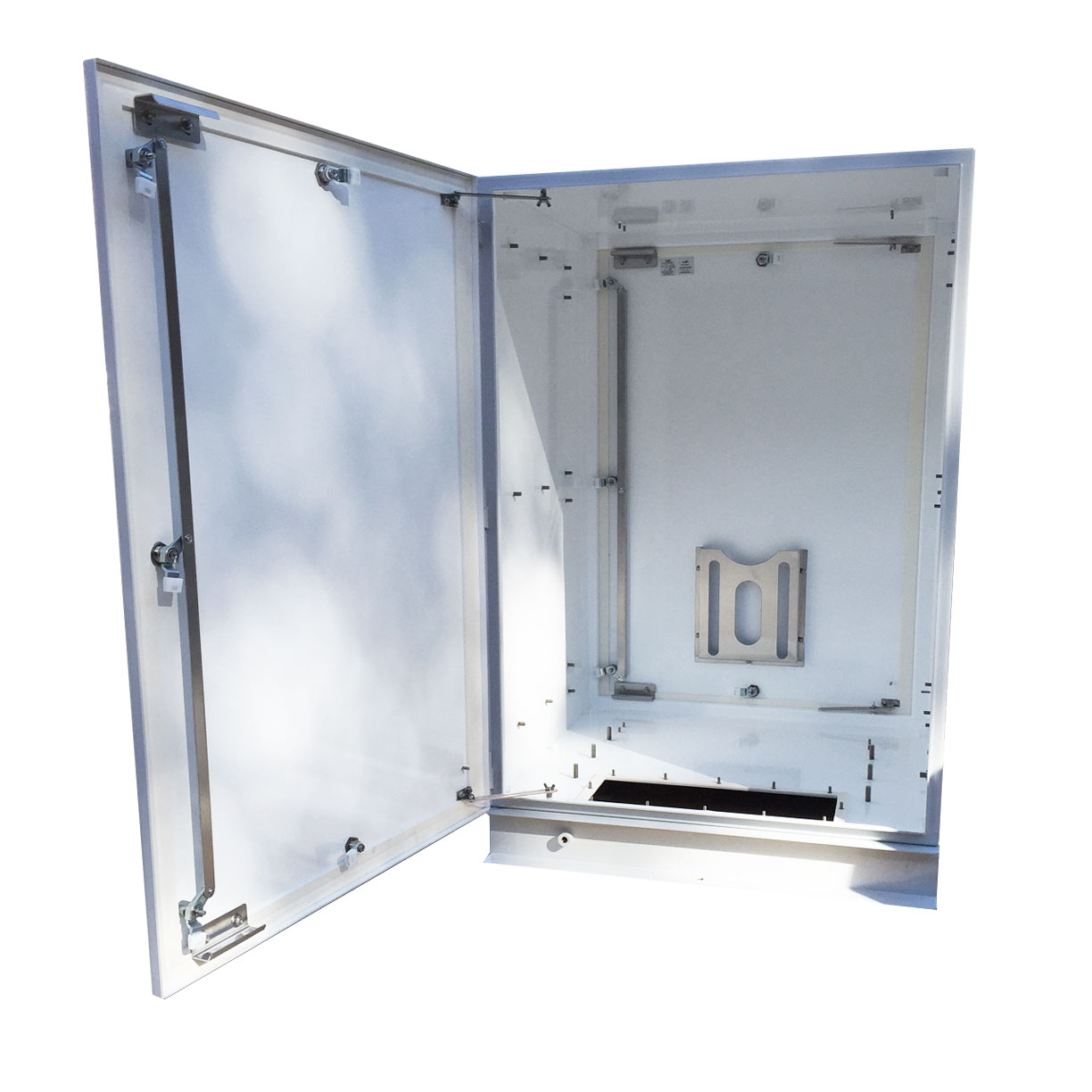

Front and rear door access panel ATEX Enclosure with unique locking mechanism for a fibre optic telecoms project in the Middle East. Painted to exact requirements inside and out and built robustly enough to withstand extreme weather conditions.

A customer a renowned leader in hazardous area wireless technology and telecoms, won a very prestigious project from a global digital service provider; and in this case, the project is ongoing in the Middle East.

Built to the highest specification in 3mm stainless steel with a bespoke paint finish, our customer will integrate the fibre optic and telecoms internally and will then be certified for use in a hazardous area when completed.

The photographs shown are of the enclosures being readied for packaging and transport to our customer in the UK.

ATEX Enclosures

Hazardous Area Fibre Optic Panels

Hazardous Area Zones

Thorne & Derrick International are Specialist Distributors of Hazardous Area Electrical, Mechanical, Process & Instrumentation Equipment to the UK and global oil, gas, petrochem and hazardous area and explosive atmospheres industries.

Our extensive product range combined with the knowledge of our trained EX product specialists provides world-class customer service and support to the industry.

T&D consolidate your supply chain by providing single-source logistics delivered to any international location – supplying explosion proof Zone 1, Zone 21, Zone 2 and Zone 22 hazardous area equipment in compliance with ATEX & IECEx international classifications (Class/Division/Zone).

ELECTRICAL & PROCESS INSTRUMENTATION EQUIPMENT

FOR EXPLOSIVE ATMOSPHERES

Thorne & Derrick are Specialist Distributors of Hazardous Area & Explosion Proof Equipment with IECEx & ATEX Certifications suitable for Zone 1 and Zone 2 hazardous areas in the following onshore and offshore oil, gas, petrochemicals and process industries.

Hazardous Area Lighting | ATEX Control Panels | Zone 1 & Zone 2 Isolators | | ATEX Plugs & Sockets | Zone 1 & Zone 2 Enclosures | Hazardous Area Electrical Heating | ATEX Gas Detectors | Hazardous Area IBC & Drum Heating

ATEX Solutions for the Oil & Gas Industry

Delivering safety critical ATEX cabinet enclosures and fabrications for client’s customised needs means that there cannot be compromise on a single component. Experts in steel fabrications ATEX enclosures are fast becoming a byword for the highest quality products with rapid delivery. Cost effectiveness and understanding that many of clients must work up to SIL 3 (Safety Integrity Level) – this is reflected in the design and build of every ATEX enclosure.

It’s crucial in the oil and gas industry for integration in all facets of the upstream, midstream and downstream processes, here are some examples of where ATEX enclosures and cabinets have been implemented:

- Process control systems (SCADA)

- Testing and sampling systems

- BOP (Blow Out Preventers)

- Shut down systems

- Turbo compressor units

- Fire and Gas systems

- Control and instrumentation systems

- Shale Gas Fracking control and process systems

- Wellhead systems

- High voltage and distribution solutions

- Foundation Fieldbus

- Battery and transformer crates

- Intrinsically safe for use in Zones 1 & 2

- Purge and pressure systems

Key Product Categories: Control Panels | Plugs & Sockets | Isolators | Enclosures & Junction Boxes | Lighting | Control Stations | Motor Starters | Heat Trace Cables & Systems | Gas Detection & Detectors | Fire Detection & Detectors | Heat Detectors | Electrical Heating & Heaters