ATEX Safety | Prevention

Published 07 Jan 2021

A Series of Articles to educate and inform those involved in the Hazardous Area & Explosive Atmosphere industries.

This Article is number 6 of 8 in the ATEX Safety & Explosive Atmospheres series.

Republished with the kind permission of Declan Barry, Managing Director of ATEX Explosion Hazards Ltd.

Also in association with INBUREX Consulting.

Declan Barry has an objective to make the industry safe by installing the  appropriate explosion protection solutions to industry with full back up services. With 42 years of experience providing Explosion Hazard Services to the process industry, ATEX Explosion Hazards Ltd have a wide range of expertise within their group of companies.

appropriate explosion protection solutions to industry with full back up services. With 42 years of experience providing Explosion Hazard Services to the process industry, ATEX Explosion Hazards Ltd have a wide range of expertise within their group of companies.

This is the sixth in a series of eight articles, which aim to help you establish a simple basis of safety in your plant and dispel some of the myths associated with process and safety risk assessments.

ATEX Safety Prevention

As mentioned in the first ‘introductory’ article, prevention of the formation of an explosive atmosphere, including the application of appropriate ventilation, is an acceptable approach to control of risk.

Prevention techniques can be simple, dilution for example, equally applicable to certain types of solvent handling operations and evaporative Ovens / Dryers as dust extraction systems.

The question is – can we under all normal and abnormal operations? control (i.e. eliminate) one of the THREE basic components for combustion?

control (i.e. eliminate) one of the THREE basic components for combustion?

Codes of practice, for Dryers and Ovens in which flammable substances are released, set out basic design criteria (dilution of the vapour). This is aimed at processes where the flammable VOC concentration exceeds 3 % of the Lower Explosive Limit.

Essentially, the ‘maximum admissible quantity of flammable substance’ needs to be determined and controlled against the ‘minimum forced ventilation flowrate’ in order to maintain conditions below the ‘maximum admissible concentration’ below the LEL. This includes any short-term operations. Indeed, a formal HAZOP study, which examines ALL of the conditions which can lead to the formation of extensive flammable atmospheres inside plant equipment, should be undertaken to allow the necessary ventilation rates to be determined.

Dilution

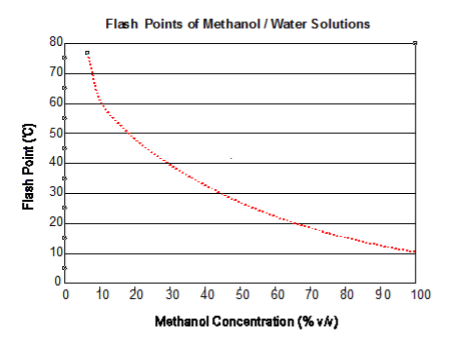

Following on from the first Introductory Article, water miscible solvents can be made ‘safer’ simply by adding water, to an alcohol for example. If the maximum ambient temperature is (say) 25 ˚C, using a 5K safety factor, concentrations up to 40 % v/v would be permissible.

Dilution of the liquid is sometimes employed where solvents are used for cleaning purposes, thereby eliminating the formation of hazardous areas (and the potential for ignition) both inside and outside equipment.

Ventilation

Ventilation (or rather Extraction) can be employed to dilute airborne dust, in a spray coating operation for example.

Typically, a primary source of release will exist within the confines of the spray / extraction hood (i.e. ‘concentration gradients’ will exist between the source [spray head] and the ventilated surroundings, allowing localised flammable atmospheres to occur) but, given the correct level of ventilation, flammable atmospheres (hazardous areas) should not extend in to the extraction system.

The necessary extraction rates are determined from the spray rates. For example, at a mass feed rate of 355 g.min-1 per gun at 100 % and 24 gun operation, assuming 50 % overspray, the mass feed rate to the extraction system is 256 kg.hr-1.

As a rule, the maximum concentration within the ductwork should be 25 % MEC (typically between 10 – 100 g.m-3) and in view of the fact that the airflow through the extraction ductwork forms part of an explosion safety system, this should be monitored or (at least) afforded a flow switch to indicate poor performance i.e. reduced ow.

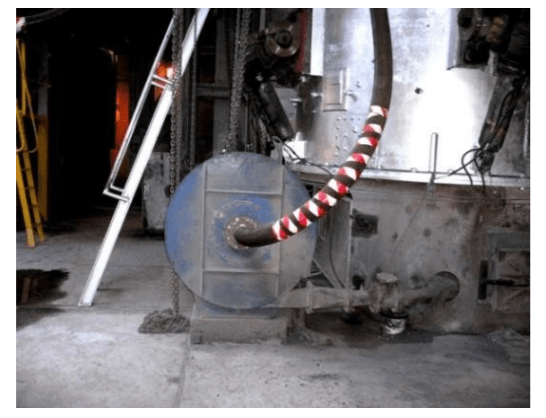

Ventilation also plays a key ‘preventative’ role in gas- red systems e.g. Boilers, Burners, etc. Efficient and effective ventilation can render a Boiler House as Zone 2 (NE) i.e. of negligible extent.

Gas detection has a role to play also, when interlocked to the supply and thereby limiting the persistence of the hazardous area. The siting of the detector head is critical, however; governed by neighbouring equipment and local air movement due to thermal gradients and forced or natural ventilation.

Smoke tests (or children’s’ ‘Bubbles’ – YES, BUBBLES) can be used to check that there is free movement of air around the equipment i.e. to ensure that the proposed ventilation is effective at the point of interest and the Zone 2 NE (negligible extent) designation can be upheld.

Inerting

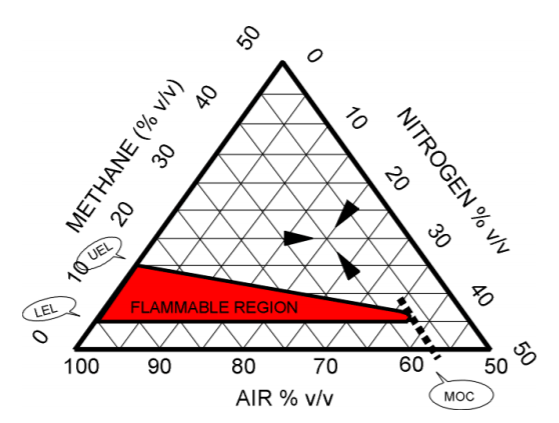

Inerting is another preventative technique but here, we are controlling the Oxidant concentration rather than the fuel. The diagram (below) expresses the flammability characteristics (or ‘envelope’) for methane, depicting lower and upper explosive limits and the ‘nose’ of the curve at which the MOC occurs. The principle of the flammability envelope also holds for vapours and airborne dusts i.e. as the oxygen concentration is reduced, the lower and upper flammability limits converge to a point where flame propagation cannot be sustained.

Inert gas blanketing or purging is commonly used as the sole basis of safety. Thus, it is imperative to maintain the reduced oxygen level inside the processing environment whilst the potential source of ignition may be present

It can be seen that a reduction in oxygen content does not change the lower limit value but markedly reduces the upper limit. This is because oxygen is in excess at the lower flammable limit.

Generally, a safety factor is applied to the required oxygen level (MOC or LOC [Limiting Oxygen Concentration]) to take account of changes in environmental conditions and also, to allow for inaccuracies that may arise when monitoring or sampling the internal atmosphere – a safety factor of 2.0 – 3.0% below the limiting value is recommended.

Literature information (NFPA 69 Explosion Prevention Systems Appendix C Table C-1 – National Fire Protection Association) indicates an MOC value of 9.5 % by volume for Toluene, where nitrogen is the purge gas. Hence, the design basis value would be a maximum of 5 % oxygen by volume under normal running conditions with shut down at 7.5 % oxygen by volume.

It must be borne in mind that MOC values like flammability limits, are pressure and temperature dependent. Also, gases other than nitrogen can be used for inerting purposes e.g. halogenated compounds, water vapour, carbon dioxide, etc. and their efficiency is dependent upon their gaseous specific heat capacity.

Inert gas blanketing/purging is used in many industries as a Basis of Safety e.g. Metal Purification, Pharmaceuticals, Coal Handling Plant (Mills), etc.

Even ‘partial inerting’ has benefits. This is where the concentration of the oxidant lies above the MOC value but below the prevailing atmospheric level. Flame propagation can still occur but at a reduced rate, depending on the extent of oxygen depletion. In such cases, the gas/vapour-air or dust-air mixtures will lie within the flammable envelope but at a point where the explosive limits are closing.

This influences not only explosion severity but also ignition sensitivity – combustion through the mixture can still occur but the explosion effects will be reduced. Ignition sensitivity will decrease also. A reduction in oxygen content can result in marked increases in both hot surface ignition temperature and minimum ignition energy.

As discussed in previous Articles, we can base safety on ‘Elimination of Ignition Sources’ IF the basis for the hazardous area classification (Zoning) is sound, ALL equipment within the Zones is correctly ATEX certified AND we don’t introduce ‘user’ or process intrinsic ignition sources such as static electricity, smoulders, hot surfaces, etc.

Control of Ignition Sources

We cannot stress this enough – without knowing the ignition sensitivity of the material (be it gas, vapour, mist or dust), we cannot assess the ignition potential with any accuracy. Likewise, we need to know the extent of the hazardous Zones accurately so we can assess which operations / equipment can give rise to the ignition sources.

Intrinsic ignition sources are those which exist solely due to the operation, for example:

- Electrostatic sparks (poly-liners, unearthed

personnel, etc.) - Thermite sparks (aluminium scoops, foil, etc.)

- Mechanical friction (screw feeders, milling,

etc.) - Pyrophoricity (metal powders, catalysts, etc.)

- Smouldering deposits (dryers, grinders, etc.)

- Auto-ignition (dryers, furnaces, etc.)

So, in essence, ignition prevention depends on how thorough you are AND how competent you are in identifying sources of ignition which might become EFFECTIVE, i.e. capable of igniting the flammable atmosphere under the prevailing process conditions (taking in to account temperature, concentration, moisture level, particle size, etc.).

But the consequences can be huge if you get it wrong!

This is the sixth in a series of eight articles, which aim to help you establish a simple basis of safety in your plant and dispel some of the myths associated with process and safety risk assessments. The next article in the series is entitled ‘Protection’ and covers the steps needed protect personnel and plant by mitigating the effects of an ignition or explosion if one happens.

More Explosion Hazards Articles

- ATEX Safety | Establishing A Basis Of Safety In Explosive Atmospheres

- ATEX Safety | Characterising Material Hazards

- ATEX Safety | Hazardous Area Classification

- ATEX Safety | Potential Sources of Ignition

- ATEX Safety | Static Ignition & Thermal Instability

- ATEX Safety | Protection

- ATEX Safety | Management Procedures

EXPERTS IN EQUIPMENT FOR EXPLOSIVE ATMOSPHERES

LEADERS IN ATEX INNOVATION TO THE HAZARDOUS AREA INDUSTRIES

Thorne & Derrick are leaders in the development and distribution of Product Innovations that deliver significant improvements to clients plant, people and operational safety in the explosive atmosphere industries.

Your proactive problem solvers experienced in succession planning for the replacement of obsolete, non-conformant and legacy equipment in hazardous areas.

Your first-choice provider of innovative and competitive solutions to ensure ATEX & IECEx Compliance for Hazardous Area Electrical, HVAC & Process Instrumentation Equipment to UK and international projects.

Control Panels | Plugs | Isolators | Enclosures & Junction Boxes | Lighting | Control Stations | Motor Starters | Heat Trace | Gas Detection | Flame Detection | Process Instrumentation | Process Heating | Ventilation Fans | Security Access Control

Competitive Prices | Extensive Stocks | Technical Support | Express Delivery