VEGAMET 861 Controller & Display Instrument | VEGA Level Sensors

Controller & Display Instrument

VEGA Level Sensors

VEGAMET 861

The VEGAMET 861 controller & display instrument feeds the connected 4 … 20 mA VEGA level sensor, processes the measured values and displays them. A large display for data visualisation is integrated in the housing designed for rough field conditions. It enables a simple conversion of pump controls, flow measurements on open channels and weirs and totalizers.

With VEGAMET 861, limit values can be reliably monitored and relays can be switched, e.g. for an overfill protection according to WHG. Due to its various possibilities it is suitable for many industrial branches.

The VEGAMET 861 has a clear display that is easy to read in sunlight and darkness and the controller eliminates the need for complex programming of control tasks.

VEGAMET 861 Controller & Display Instrument

Technical Specification

| Protection Rating | IP66/IP67, Type 4X |

| Input |

1 x 4 … 20 mA/HART sensor input

2x digital input

|

| Output |

1 x 0/4 … 20 mA current output

1x failure relay (instead of operating relay)

4x operating relay

|

| Ambient Temperature | -40 … 60 °C |

| Measured Value Memory |

Internally

SD card

|

The VEGAMET 861 controller can power the connected sensor and process its measurement signals. The requested parameter is shown on the display and also output to the integrated current output for further processing. The measurement signal can thus be transferred to a remote display or a superordinate control system. Operating relays for control of pumps or other devices are also integrated.

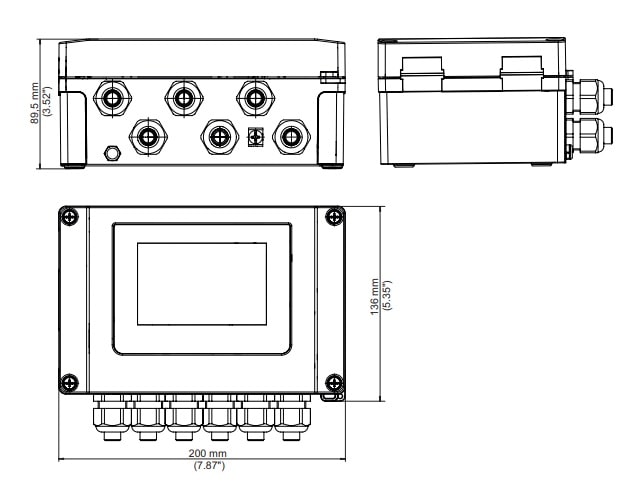

Dimensions

Application

Measurement of belt loading and mass flow in a thermal sludge drying facility

VEGAMET 861 is an universal controller for measured value processing display. Through drying, the weight and volume of the sludge is further reduced. In the thermal drying unit, which is equipped with a belt drier and a hot (+80 to +130 °C) air stream, water is removed from the sludge through evaporation. The continuous monitoring of belt loading is done by means of radiometric, i.e. radiation-based, measurement – this technique allows optimal, cost-effective dryer control.

VEGA Controls Use Sensors, Switches & Transmitters For Continuous Level, Point Level & Pressure Measurement In Process & Hazardous Area Industries.