Fisher Baumann 26000 Low Flow Valve – Stem Sliding Valves

Fisher Baumann 26000 Low Flow Valve – Stem Sliding Valves

Fisher Baumann 26000 Low Flow Valve is part of the sliding stem valve range that is suitable for additive flow control of acids and caustic pH applications.

The Baumann 26000 is corrosion resistant that features a flangeless wafer valve body and a powerful multi-spring diaphragm actuator.

The 26000 low flow valve is available with a Fisher FIELDVUE digital valve controller to allow for highly accurate, low flow control of almost all corrosive media.

Fisher Baumann 26000 Low Flow Valve

Product Features

- Wide control range with high rangeability

- Solid R05200 Tantalum or N10276 Nickel Alloy valve plug (Other materials on request)

- 316 Stainless steel valve housing with PTFE body interior

- Pressure assisted seating, up to Class VI shutoff

- The combination of primary and secondary valve stem packing insures process retention

- Flangeless body construction, unique thru-hole wafer design for installation between CL150 and 300 and PN 10 through 25 RF or FF line flanges

- PTFE encapsulated line flange gaskets (included) permit valve installation between plastic lined slip-on mating flanges

- Epoxy powder coated actuator with stainless steel fasteners for corrosion resistance

- FIELDVUE™ Digital Valve Controller available for remote calibration and diagnostics in facilities utilizing the PlantWeb™ architecture

FISHER BAUMANN 26000 LOW FLOW VALVE

PRODUCT Specification

| Sizes | NPS 1 |

| Connections | Mates between CL150, 300RF, or PN10-25 |

| Body Material | 316 SS |

| Valve Body Rating | 150 psig CWP |

| Trim Material | R05200 Tantalum or N10276 Nickel Alloy |

| Trim Characteristic | Modified Equal % |

| Seat Leakage | ANSI/FCI 70-2 Class VI, CL IV (2.5 & 4.2) |

| Cv Ratings | 0.001 to 4.2 |

| Bonnet Type | Standard threaded |

| Packing Material | PTFE V-ring |

| Temperature Range | -29ºC to 177ºC (-20ºF to 350ºF) |

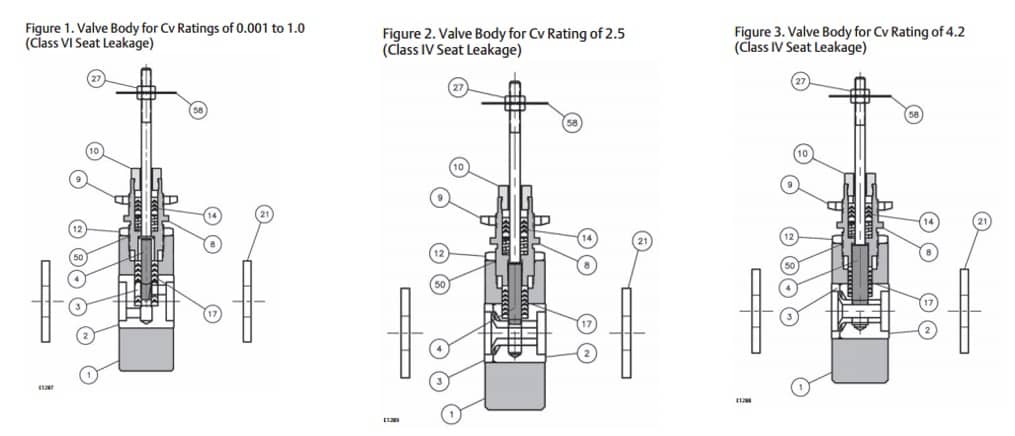

Fisher Baumann 26000 Low Flow Valve – Valve Body

FISHER BAUMANN 26000 LOW FLOW VALVE

Materials of construction

| Key No | Description | Material |

| 1 | Valve Body | ASTM A479 S31600/S31603, Annealed |

| 2 | Liner | PTFE (Polytetrafluoroethylene) |

| 3 | Spacer (Cv = 0.001 – 1.0 ONLY) | PTFE (Polytetrafluoroethylene) |

| Insert (Cv = 2.5 and 4.2 ONLY) | PTFE (Polytetrafluoroethylene) | |

| 4 | Valve Plug | ASTM B365 R05200 cold worked or ASTM B574 N10276, 35 HRC Max |

| Stop Washer | ASTM B574 N06022, 35 HRC Max | |

| Stem | ASTM B574 N10276, 35 HRC Max | |

| 8 | Bonnet | ASTM A479 S31600/S31603, Annealed |

| 9 | Yoke Drive Nut | S30400 Stainless Steel |

| 10 | Packing Follower | ASTM A276 S31600 Condition A |

| 12 | Hex Clamp Nut | ASTM A582 S30300 Condition A |

| 14 | Secondary Packing Kit, Spring Loaded PTFE V-Ring Packing Kit | Refer to figure 4 and table 1 see data sheet |

| 17 | Primary Packing, V-Ring | PTFE (Polytetrafluoroethylene) |

| 21 | Line Flange Adapter Gaskets(1) | PTFE (Polytetrafluoroethylene), Steel Core |

| 27 | Locknut | 18-8 Stainless Steel |

| 50 | Bonnet Seal | PTFE (Polytetrafluoroethylene) |

| 58 | Travel Indicator | ASTM A240 S30400 |

1. It is highly recommended that the included PTFE encapsulated line flange adaptor gaskets be utilised

See how Fisher Control Valves provide safe, efficient and intuitive flow control.

Fisher Rotary Valves: Flow Control For Power, Oil, Gas & Refining Pipelines

➡ Did you know? Fisher Control Valves are approved, certified and classified to international standards including ASME, CSA, IEC, NACE, FDA & NFPA. Should you require assistance with valve specification for explosion-proof or intrinsically safe applications in the hazardous area industries, please contact T&D.

Fisher Control Valves – Approvals