ATEX Safety | Management Procedures

Published 13 Jan 2021

A Series of Articles to educate and inform those involved in the Hazardous Area & Explosive Atmosphere industries.

This Article is number 8 of 8 in the ATEX Safety & Explosive Atmospheres series.

Republished with the kind permission of Declan Barry, Managing Director of ATEX Explosion Hazards Ltd.

Also in association with INBUREX Consulting.

Declan Barry has an objective to make the industry safe by installing the  appropriate explosion protection solutions to industry with full back up services. With 42 years of experience providing Explosion Hazard Services to the process industry, ATEX Explosion Hazards Ltd have a wide range of expertise within their group of companies.

appropriate explosion protection solutions to industry with full back up services. With 42 years of experience providing Explosion Hazard Services to the process industry, ATEX Explosion Hazards Ltd have a wide range of expertise within their group of companies.

This is the final article in a series of eight articles, which aim to help you establish a simple basis of safety in your plant and dispel some of the myths associated with process and safety risk assessments.

Management Procedures

Do we need to take precautions, as part of our managerial responsibilities and if so, why and to what extent? Well, there may be a risk of injury or fatality (to Plant Operators or members of the public), there are Statutory Requirements (Legal Obligations) which we must adhere to and there are consequences when things go wrong:

- Interruption to the business

- Fines for breach in legislation

- Loss of market share

- Loss of customer confidence

- Harm to corporate image

Risk Matrix

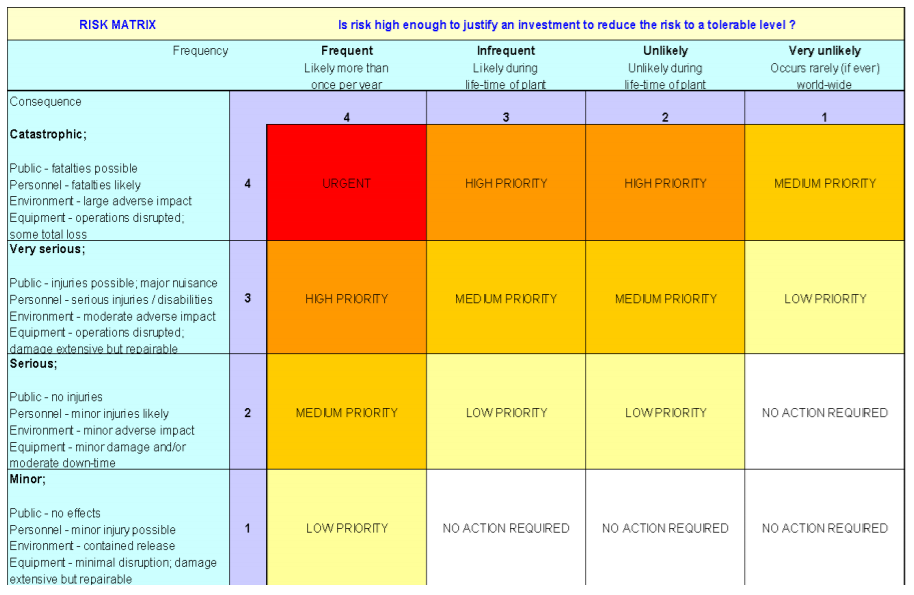

We need to ask ourselves, is the risk we have identified, high enough to justify the investment in order to reduce it to a tolerable level. To this end, a commonly used Risk Matrix is shown below.

More detailed forms of the matrix with costs, event frequencies, etc. are available but this shows the general idea.

Today, risk assessments are common place and used in all walks of life, often without a proper understanding of the true meaning i.e. risk is the product of probability (of the undesired event) and consequence. The categorization of a risk as insignificant does not necessarily mean that it will be perceived as such by those affected; it relates rather to the action required by the decision maker.

Neither does tolerable mean acceptable – it refers to the willingness to live with a risk to secure certain benefits and in the confidence that it is being properly controlled. To tolerate a risk means that we do not regard it as negligible or something we might ignore, but rather as something we need to keep under review, and reduce still further if, and as, we can (Hazard Identification and Risk Assessment – Geo Wells, IChemE 1996).

Management Obligations

Management obligations are wide ranging and for that reason, they can be quite daunting. However, some simple measures can be put in to place which not only help massively reduce risk but also do it both effectively and economically.

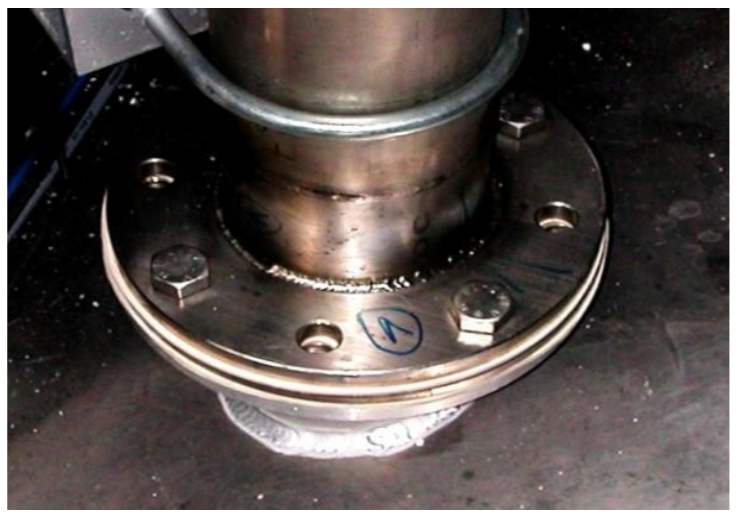

For example, bearing in mind the need to control releases of the ‘hazardous material’, all equipment must be well maintained and subject to regular inspections, in line with good engineering practice. The use of improper seals/joints IS NOT acceptable. For example, ‘gaffa tape’ should never be used on leaking joints. Moreover, there is a tendency for this type of temporary fix to become permanent. Likewise, seals (and replacement thereof) need to be robust to reduce the extent of dust egress.

Items of plant and equipment must be sealed effectively i.e. not simply relying on gravity to hold a door or panel shut. For example, often inspection hatches are not bolted down – although this might be considered unnecessary for (say) granular materials, it sends the wrong message to operators and maintenance staff (e.g. there should be a

consistent approach).

Such items should be bolted shut and form an effective seal; although this may not lead to the formation of a hazardous area per se, fugitive emissions from poorly sealed plant will give rise to housekeeping issues.

Some inspection hatches, which by their nature are opened routinely, should be sealed and afforded a ‘quick-release’ opening mechanism e.g. sprung-loaded, whilst other ‘access’ panels should be sealed and bolted shut.

Air-jetting (on dust deposits) must not be used – this simply moves dust around in to spaces which are even more inaccessible and it aggravates the problem. Use of dust extraction points (where provided) or vacuuming when opening up equipment should be encouraged – this will help reduce the cleaning frequency.

If extraction is provided for dust control, make sure the ‘capture’ velocities are correct for the materials in use. Also, all too often there is no indication of poor performance i.e. low flow, so fit a low-flow (LF) alarm with low-low-flow (LLF) trip.

If the extraction fails, you’ll know about it rather than throwing manpower at what appears to be more and more dust deposits!

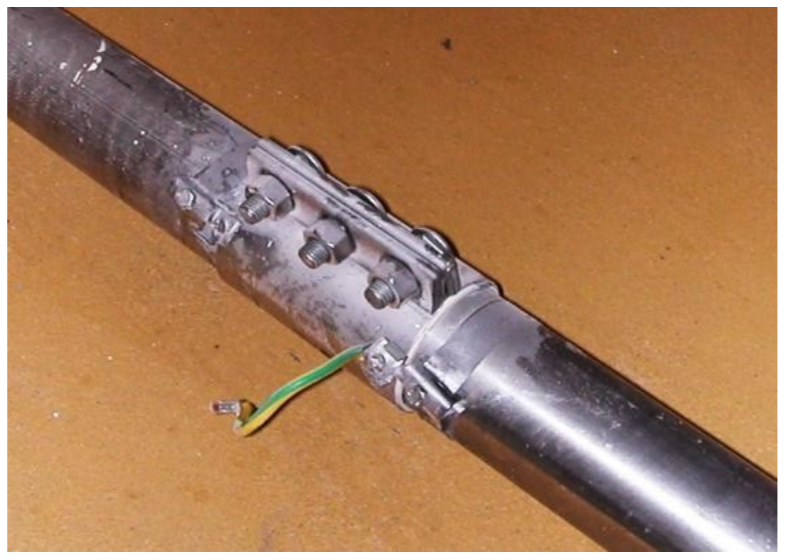

From an operational (and safety) viewpoint, Conveyors should comprise one or a combination of the following – blockage detection, tracking sensors, motor overload protection, rotation sensors, etc. and ALL metal items should be bonded to earth.

Procedures must be in place which ensure that Hot Work is controlled. Indeed, ALL plant personnel must be made aware of both the potential ignition/explosion hazards associated with their plant and the means of control. To this end, formal DSEAR / ATEX Training Sessions should be conducted on a regular basis and Attendance Certificates issued.

HAZOP studies should be considered. This is a form of design review – the key features being it is a team study, it concentrates on how well the design will cope with abnormal conditions (rather than how well it will perform in normal operation) and it is systematic and detailed. A study considers each process stream or pipeline and vessel examining for each possible cause and consequence of a wide range of process upsets or abnormalities. It is a very thorough but mainly qualitative approach to ‘Failure Mode and Effect Analysis’. When done correctly, the technique is extremely powerful, often highlighting many ‘operability’ issues not just ignition hazards.

Management of Change Procedures

Portable equipment is often brought in to work areas for a specific reason and with good intentions e.g. more heat, more light, etc. However, it is essential that you assess this ‘change’ i.e. follow your Management of Change Procedures – assuming you have some of course!

IF NOT, WHY NOT? The heat lamp may have zero consequences, but there again, it might have been brought in to increase the evaporation rate of solvent wet material – Yes, it happens!

As we’ve said, electrical and mechanical equipment must be certified for the specific hazardous area AND ‘process specific’ sources such electrostatic ignition e.g. from solvent or powder transfers, etc.

Predictive Maintenance

Good engineering practices and strict maintenance regimes are vital also. Hopefully, the days of ‘if it ain’t broke don’t fix it’ are long gone; and now there is a ‘new kid’ on the block – Predictive Maintenance

The potential failure of ‘process critical’ or ‘safety critical’ items should be monitored since this will help identify problems BEFORE they arise – the key benefit being that YOU shut down the plant when it’s convenient to you rather than having an unscheduled breakdown (which is never convenient). In the example shown below, Roller Bearing defects were identified early, by vibration monitoring.

ATEX Establishing a Basis for Safety

This is the eighth and final article in our series which aims to help you establish a simple basis of safety in your plant and dispel some of the myths associated with process and safety risk assessments. We hope you have found this series of articles both informative and helpful Stay safe.

More Explosion Hazards Articles

- ATEX Safety | Establishing A Basis Of Safety In Explosive Atmospheres

- ATEX Safety | Characterising Material Hazards

- ATEX Safety | Hazardous Area Classification

- ATEX Safety | Potential Sources of Ignition

- ATEX Safety | Static Ignition & Thermal Instability

- ATEX Safety | Prevention

- ATEX Safety | Protection

EXPERTS IN EQUIPMENT FOR EXPLOSIVE ATMOSPHERES

LEADERS IN ATEX INNOVATION TO THE HAZARDOUS AREA INDUSTRIES

Thorne & Derrick are leaders in the development and distribution of Product Innovations that deliver significant improvements to clients plant, people and operational safety in the explosive atmosphere industries.

Your proactive problem solvers experienced in succession planning for the replacement of obsolete, non-conformant and legacy equipment in hazardous areas.

Your first-choice provider of innovative and competitive solutions to ensure ATEX & IECEx Compliance for Hazardous Area Electrical, HVAC & Process Instrumentation Equipment to UK and international projects.

Control Panels | Plugs | Isolators | Enclosures & Junction Boxes | Lighting | Control Stations | Motor Starters | Heat Trace | Gas Detection | Flame Detection | Process Instrumentation | Process Heating | Ventilation Fans | Security Access Control

Competitive Prices | Extensive Stocks | Technical Support | Express Delivery