ATEX Safety | Potential Sources of Ignition

Published 06 Jan 2021

A Series of Articles to educate and inform those involved in the Hazardous Area & Explosive Atmosphere industries.

This Article is number 4 of 8 in the ATEX Safety & Explosive Atmospheres series.

Republished with the kind permission of Declan Barry, Managing Director of ATEX Explosion Hazards Ltd.

Also in association with INBUREX Consulting.

Declan Barry has an objective to make the industry safe by installing the  appropriate explosion protection solutions to industry with full back up services. With 42 years of experience providing Explosion Hazard Services to the process industry, ATEX Explosion Hazards Ltd have a wide range of expertise within their group of companies.

appropriate explosion protection solutions to industry with full back up services. With 42 years of experience providing Explosion Hazard Services to the process industry, ATEX Explosion Hazards Ltd have a wide range of expertise within their group of companies.

This is the fourth in a series of eight articles, which aim to help you establish a simple basis of safety in your plant and dispel some of the myths associated with process and safety risk assessments.

ATEX Safety Sources Of Ignition

EU ‘ATmosphere EXplosif’ (ATEX) Directives require manufacturers to provide safe (certified) equipment for use in hazardous areas under the Equipment Directive previously referred to as ATEX 95 now 114. Similarly, users of equipment are required to assess both the likelihood of forming a hazardous area and the risks from ignition (identification and control) under the Use Directive previously referred to as ATEX 137 now 153.

Standard BS EN 1127-1:2011

‘Explosive Atmospheres – Explosion Prevention and Protection Part 1. Basic concepts and methodology’ distinguishes between 13 types of ignition source:

| Common | Less Common |

| Mechanically generated sparks | Stray currents & cathodic protection |

| Hot surfaces (e.g. binding friction) | Electromagnetic elds (9 – 300 GHz) |

| Flames and hot gases | Electromagnetic radiation (3 x 1011 to 3 x 1015 Hz or wavelength range from 1000 µm to 0.1 µm (optical spectrum) |

| Electrical apparatus | Ionising radiation |

| Static electricity | Ultrasonics |

| Lightning | Adiabatic compression & shock waves |

| Chemical reactions (inc. spont. ignition) |

This article covers some of the more common sources. Static electricity and chemical reaction / thermal instability will be covered in a separate article.

| Equipment Category | Explosive Atmosphere | Control of ‘effective’ ignition sources |

| Cat. 1G / D | Zone 0 / 20 | No sources of ignition in normal operation, during expected malfunctions AND during rare malfunctions |

| Cat. 2G / D | Zone 1 / 21 | No sources of ignition in normal operation AND during expected malfunctions |

| Cat. 3G / D | Zone 2 / 22 | No sources of ignition in normal operation |

The table above shows the general philosophy behind matching the required level of ignition control to the likelihood of forming a flammable mixture. In practice, some of the above can be avoided, for example, by management procedures or by specification of special (i.e. suitable) equipment. However, many potential sources of ignition are present by virtue of the plant hardware, materials in use or mode of operation and as such, are inherent to the specific process and in need of control.

Source of ignition | Mechanical Sparks

Ignition risks can arise when two hardened materials come into contact with force resulting glancing impact and friction sparks.

With certain materials, the impact energy can initiate an exothermic reaction (i.e. the Thermite reaction associated with aluminium, titanium, magnesium, zirconium and their alloys), resulting in highly incendive sparks of ‘white hot’ appearance. Thermite friction sparks (particularly with rusty steel and aluminium) are known to be extremely energetic and capable of igniting many flammable gases, vapours, mists and dusts.

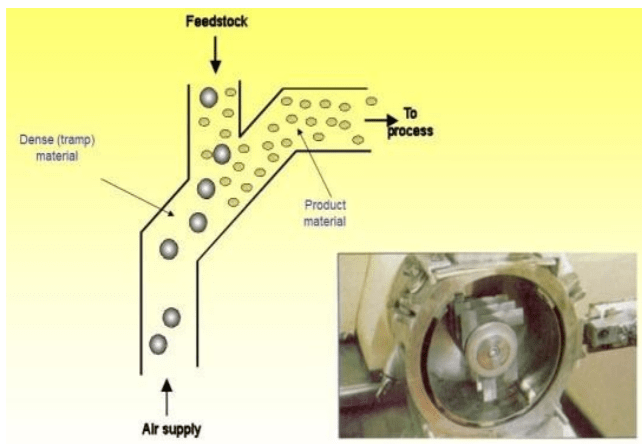

Sometimes, pneumatic separators are used in the feed supply to remove ‘debris’, upstream from a Mill, for example; a good option where metal detection may not be 100 % reliable.

In reality, the ignition risk from any form of spark depends on the sensitivity of the fuel-air mixture. More stringent requirements are needed for Group IIB and IIC gases/vapours, because of their greater sensitivity, compared to Group IIA materials.

Research has been undertaken to evaluate the ignition hazard with respect to airborne dusts and this, together with similar work in Germany, has led to a better understanding of friction spark ignition capability e.g. the effect of the level of thrust at the point of impact.

In many instances, steel-on-steel friction and grinding sparks do not give cause for concern, due to the relatively slow rotational speeds of equipment i.e. if contact occurs at all, it is likely to result in increased surface temperatures rather than multiple sparks.

Therefore, potential sources of ignition can be eliminated by maintaining low circumferential (contact) velocities i.e. below 1 m.s-1.

Hot Surfaces

In accordance with BS EN 1127-1:1998 ‘Explosive Atmospheres – Explosion Prevention and Protection’, for gases, vapours and mists, the maximum surface temperature must not exceed:

- 80% of the AIT value in C (even in the case of rare malfunctions) for Category 1 equipment (i.e. Zone 0 areas)

- 80% of the AIT value in C (during normal operation and in the case of rare malfunctions) for Category 2 equipment (i.e. Zone 1 areas)

- 100% of the AIT value in C (during normal operation) for Category 3 equipment (i.e. Zone 2 areas)

Hot surfaces can arise in many situations, both intentionally (e.g. drying operations) or spuriously (e.g. binding friction from Screw Conveyors and similar mechanised equipment, in this case the 1m/s does not apply. Hot particles from exhausts need to be eliminated in zoned areas, also.

Control of drying temperatures is of particular importance. To eliminate hot particles from direct red systems, it is necessary to:

- Clean / filtered air if re-circulated

- Clean burners regularly

- Fit 3mm mesh on air inlet to restrict large (glowing) particles

The Dryer inlet and outlet temperatures must be restricted also. Typical values for an explosion protected Dryer are:

- 50K below MIT cloud value

- 50K below MIT cloud value 10-20K below AirOver-Layer exotherm onset temp

Flames & Hot Gases

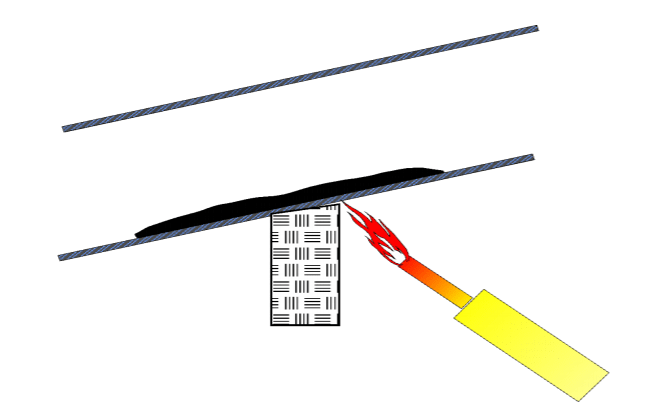

The most obvious risk of flame arises from unauthorised ‘hot-work’ and clearly procedures should be in place to ensure that this cannot arise – a near-miss was witnessed when an operator was sweeping dust from one side of a large sieve screen whilst welding work was being undertaken on the opposite side.

Hot work is a well-known cause of dust explosions and this activity needs special consideration. Instances are given in the open literature where (unknowingly) smouldering material has arisen inside the plant item, which then resulted in ignition on start-up.

In bulk storage areas, burning embers from the engine of trucks should be precluded by means of a certified flame arrester. Provided the necessary maintenance and inspection regimes, associated with this device (and any other heated surfaces e.g. engine block, manifold, etc.) are adhered to, this form of ignition hazard can be eliminated.

Electrical Equipment

Electrical apparatus used within the hazardous areas should be certified for the Gas Group (gases, vapours and mists/sprays) and the Temperature Class (‘T’ rating).

The maximum surface temperature of equipment (‘T’ rating) is the highest temperature attained in service under the most adverse operating conditions (but within the recognised tolerance) by any part or surface of the equipment which would be able to produce an ignition of the surrounding potentially explosive atmosphere.

The ‘T’ rating of equipment intended for use in flammable atmospheres and based on a max. ambient temperature of 40 °C, is listed as follows:

| Temperature Class | Max. Surface Temperature (C) |

| T1 | 450 |

| T2 | 300 |

| T3 | 200 |

| T4 | 135 |

| T5 | 100 |

| T6 | 85 |

The criteria for selection of equipment is:

- less than 2/3rds MITcloud

AND

- more than 75K below MIT5mm layer

- Using ‘typical’ wood nes as an example :

- MITcloud : 470 * 2/3 = 313 ºC

- MIT5mmlayer : 260 – 75 = 185 ºC

Therefore, the required Rating is T4 – T6 (for

max. 5mm thickness)

It is important to use the correct Ingress Protection (IP) rating also (i.e. typically IP5X or IP6X for dusts) – the first and second digits refer to restricting dust and water ingress, respectively.

In general terms, if electrical equipment needs cleaning more often than daily to keep dust deposits to negligible thickness and it is not dust tight (IP6X), it should be replaced or relocated.

Overheating of dust layers on electrical equipment (e.g. motors) leading to a re is usually a slow process. Dust layers should be removed regularly to control this problem and in any case, should not exceed 5 mm thickness.

Lightning

If lightning strikes a flammable atmosphere, ignition will always occur. Moreover, there is also a possibility of ignition due to the high temperature reached by lightning conductors.

Large currents ow from where the lightning strikes and these currents can produce sparks in the vicinity of the point of impact.

Even in the absence of lightning strikes, thunderstorms can cause high induced voltages in equipment, protective systems and components. In practice, the probability of a lightning strike depends on the specific location of the site and a specialist should be consulted to ascertain whether additional precautionary measures are required.

As a general precaution against external sources of ignition, all vents handling flammable gases and vapours should be fitted with a suitable flame-trap!

Static Ignition & Thermal Instability

The next article in this series of eight is entitled: Static Ignition & Thermal Instability.

The aim of these articles is to help you establish a simple basis of safety in your plant and dispel some of the myths associated with process and safety risk assessments.

More Explosion Hazards Articles

- ATEX Safety | Establishing A Basis Of Safety In Explosive Atmospheres

- ATEX Safety | Characterising Material Hazards

- ATEX Safety | Hazardous Area Classification

- ATEX Safety | Static Ignition & Thermal Instability

- ATEX Safety | Prevention

- ATEX Safety | Protection

- ATEX Safety | Management Procedures

EXPERTS IN EQUIPMENT FOR EXPLOSIVE ATMOSPHERES

LEADERS IN ATEX INNOVATION TO THE HAZARDOUS AREA INDUSTRIES

Thorne & Derrick are leaders in the development and distribution of Product Innovations that deliver significant improvements to clients plant, people and operational safety in the explosive atmosphere industries.

Your proactive problem solvers experienced in succession planning for the replacement of obsolete, non-conformant and legacy equipment in hazardous areas.

Your first-choice provider of innovative and competitive solutions to ensure ATEX & IECEx Compliance for Hazardous Area Electrical, HVAC & Process Instrumentation Equipment to UK and international projects.

Control Panels | Plugs | Isolators | Enclosures & Junction Boxes | Lighting | Control Stations | Motor Starters | Heat Trace | Gas Detection | Flame Detection | Process Instrumentation | Process Heating | Ventilation Fans | Security Access Control

Competitive Prices | Extensive Stocks | Technical Support | Express Delivery