ATEX Safety | Characterising Material Hazards

Published 14 Dec 2020

A Series of Articles to educate and inform those involved in the Hazardous Area & Explosive Atmosphere industries.

This Article is number 2 of 8 in the ATEX Safety & Explosive Atmospheres series.

Republished with the kind permission of Declan Barry, Managing Director of ATEX Explosion Hazards Ltd.

Also in association with INBUREX Consulting.

Declan Barry has an objective to make the industry safe by installing the  appropriate explosion protection solutions to industry with full back up services. With 42 years of experience providing Explosion Hazard Services to the process industry, ATEX Explosion Hazards Ltd have a wide range of expertise within their group of companies.

appropriate explosion protection solutions to industry with full back up services. With 42 years of experience providing Explosion Hazard Services to the process industry, ATEX Explosion Hazards Ltd have a wide range of expertise within their group of companies.

This is the second in a series of eight articles, which aim to help you establish a simple basis of safety in your plant and dispel some of the myths associated with process and safety risk assessments.

materiaL Hazards

This article focuses on Characterising Material Hazards

Industries producing and/or handling materials, which may form hazardous (flammable) atmospheres, must comply with the ATEX Directives.

In the UK, this requires compliance with the Dangerous Substances & Explosive Atmospheres Regulations (DSEAR). Similar NFPA Codes apply In the USA.

You cannot define the necessary systematic approach to protecting people and plant, without a knowledge of the potential material hazards in your work place: are flammable atmospheres present within your plant or processing areas?

The first step is to check your suppliers’ MSDS’s, your own records and the open literature for relevant test data.

Gestis is an EU funded database of combustion and explosion characteristics of more than 6000 dust samples from virtually all sectors of industry to help establish a basis of safety for the safe handling of combustible dusts. Gestis data is generic and may be indicative only e.g. it may not cover specific formulations or compounds, in which case, testing will be required.

Where a dangerous substance is or is liable to be present at the workplace, the employer shall make a suitable and sufficient assessment of the risks to his employees which arise from that substance.

— Gestis

MAterial HAzards

How do you know a material is dangerous unless you test it?

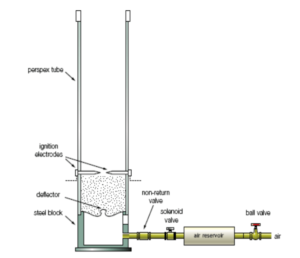

Group A/B (Vertical Tube) Test: Essentially, the dust under test is dispersed in air at ambient temperatures, past a source of ignition and observations of flame propagation made by the operative. The photograph shows the test apparatus with the tube removed for clarity. This classification test is a qualitative assessment of the ability of a dust to take part in an explosion:

- Group A is a dust, which is able to ignite and propagate flame.

- Group B is a dust, which does not propagate flame

characterising material hazards

As in all explosion testing, the sample selected must be representative of the material from the plant at risk, typically the finest and driest material found.

Further testing is required for Group B samples if handled at elevated temperatures >110 degree C. Although this test may be superseded by the 20-litre sphere, it does give a very good visual feel for how the dust reacts to an ignition source at ambient temperature.

Once you have established that the dust is Group A Explosible, the next step is to examine the specific ignition and explosion parameters.

MAterial hazards | Dust Concentration

Lower Explosion Level (LEL for gases and vapours) or Minimum Explosible Concentration (MEC for powders) is typically of the order 45g/m3 and 30-60 g/m3 respectively. The Upper Explosion Level (UEL) is not as clearly defined for powders, but usually is >1000g/m3.

Do you leave footprints where you walk?

If so, there may be a secondary explosion risk. Consider a room 10 m x 10 m x 5 m high. What thickness of deposits will form a flammable (explosible) atmosphere throughout the room? A thickness of just 1 mm can equate to 75 kg of powder (depending on density) and if this was dispersed in the 500 m3 volume, the resulting concentration is 75,000 / 500 = 150 g/m3 i.e. well within the flammable range. How might this be dispersed, you may ask? During cleaning operations using air-jetting!

PArticle Size

This is a very important factor as particles greater than 500micron are unlikely to cause dust explosion hazards. This is why most tests are carried out below 100 micron or the standardised 63 micron. This may be a futile action due to attrition, as transportation of granular material may create a fines fraction.

MAterial hazards | Moisture Effects

Explosion violence falls at higher moisture contents:

- 0-5% has little effect

- 5-10% decreases sensitivity

- >25% particles unlikely to stay in suspension

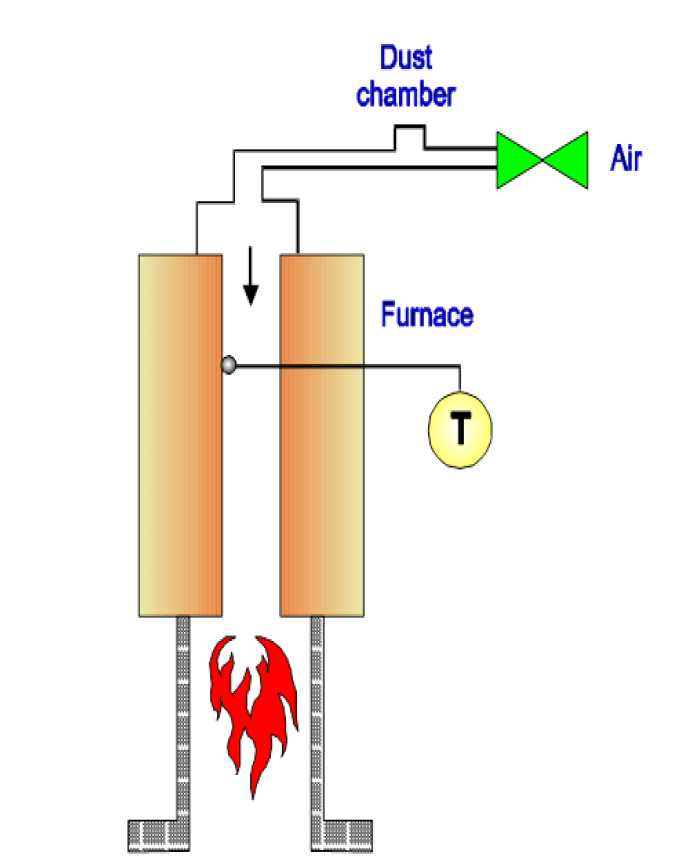

Minimum ignition temperature: MIT Cloud

The Minimum Ignition Temperature of a dust suspension is the lowest temperature at which it will ignite spontaneously and propagate flame. This MIT value is particularly relevant to problems involving relatively large heated areas of plant e.g. surfaces of dryers, mills, electrical equipment, etc.

For example, you need to ensure that any escape of dust (as a cloud) does not spontaneously ignite on nearby heated surfaces e.g. electrical motors, insect-o-cuters, etc.

Ancillary equipment such as this is often ‘missed’ (overlooked) when shutting down plant for cleaning and maintenance purposes.

Minimum ignition temperature

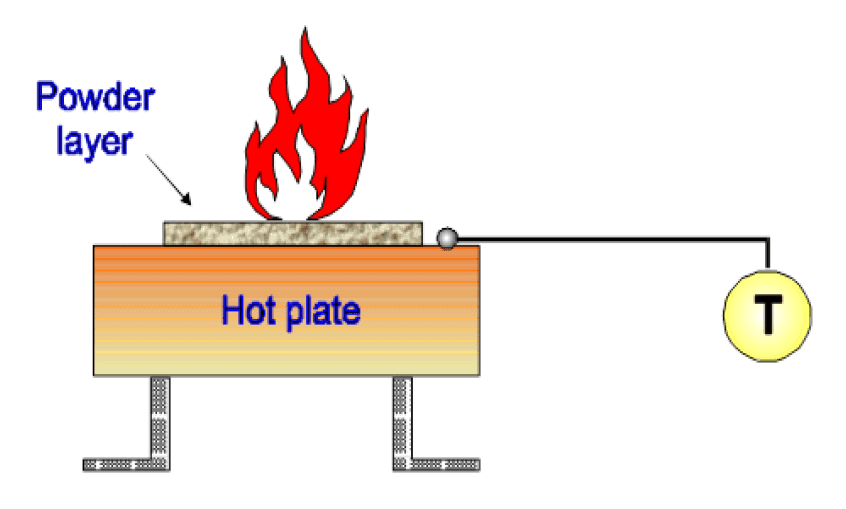

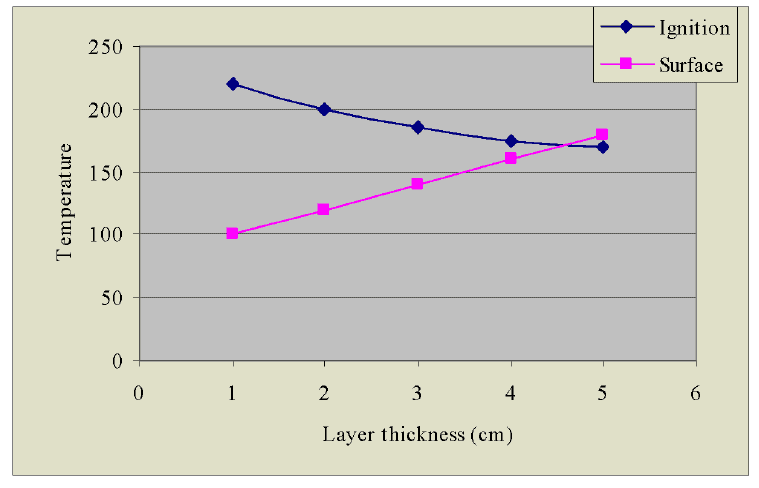

MIT (LIT) 5 mm Layer

The test determines the minimum temperature of a prescribed hot surface, which will result in the decomposition and/or ignition of a layer of powder of specified thickness. The test is particularly relevant to industrial equipment with hot surfaces, on which dust deposits may form. For example, you need to ensure that any escape of dust (which forms a layer) does not result in smouldering. Equipment must be kept clean with surface layers not exceeding 5 mm. Thicker layers will invalidate the T class rating of equipment and may cause ignition.

Minimum ignition Energy: The Dust cloud

Minimum Ignition Energy of a dust suspension is the lowest energy at which ignition and flame propagation away from the spark kernel occurs – the value being particularly relevant to identifying potential electrostatic ignition hazards. In principle, the test is similar to the Group A/B Test. Two circuits are employed – capacitive (for electrostatic ignition) and inductive (for friction spark ignition). Essentially, the difference between them lies in the duration of the spark i.e. increasing inductance will lengthen the duration of the discharge making it more incendive. Consequently, the MIE value with this circuit will be lower than that with a capacitated circuit e.g. 10 mJ compared to 30 mJ. Typically, MIEcap values range from 3 – 1000 mJ for dusts and 0.017 – 0.4 mJ for gases and vapours.

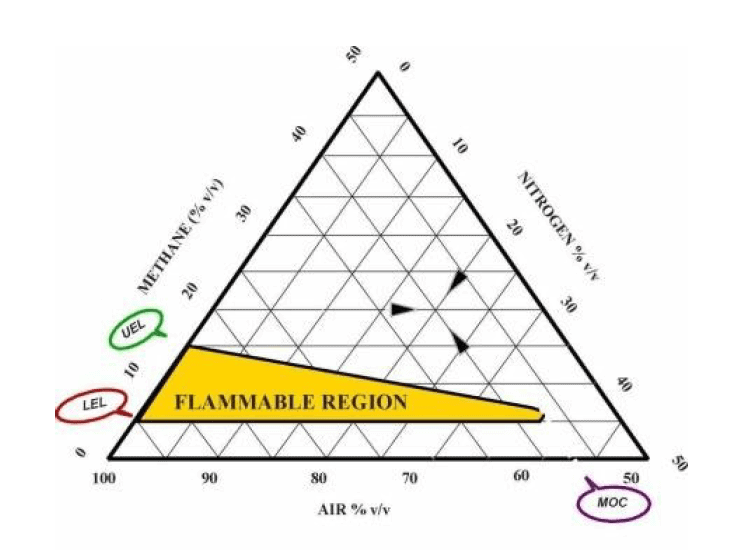

Minimum Oxygen for Combustion / Limiting Oxygen Concentration (MOC / LOC)

Essentially, a flammable atmosphere (be it gas, vapour or airborne dust) cannot exist below this level of depleted oxygen. The data is needed when basing safety on the use of inert gas, in certain milling or solvent handling operations, for example. The test is conducted in a 20 Litre Explosion Sphere. Typical MOC values lie in the range 8 – 15 % v/v (for powders) and 5 – 10 % v/v for gases and vapours. It is important to note that the MOC value depends on the type of material and the type of inert gas.

The schematic shows the flammable envelope for Methane.

Explosion Characteristics: Kst & Pmax

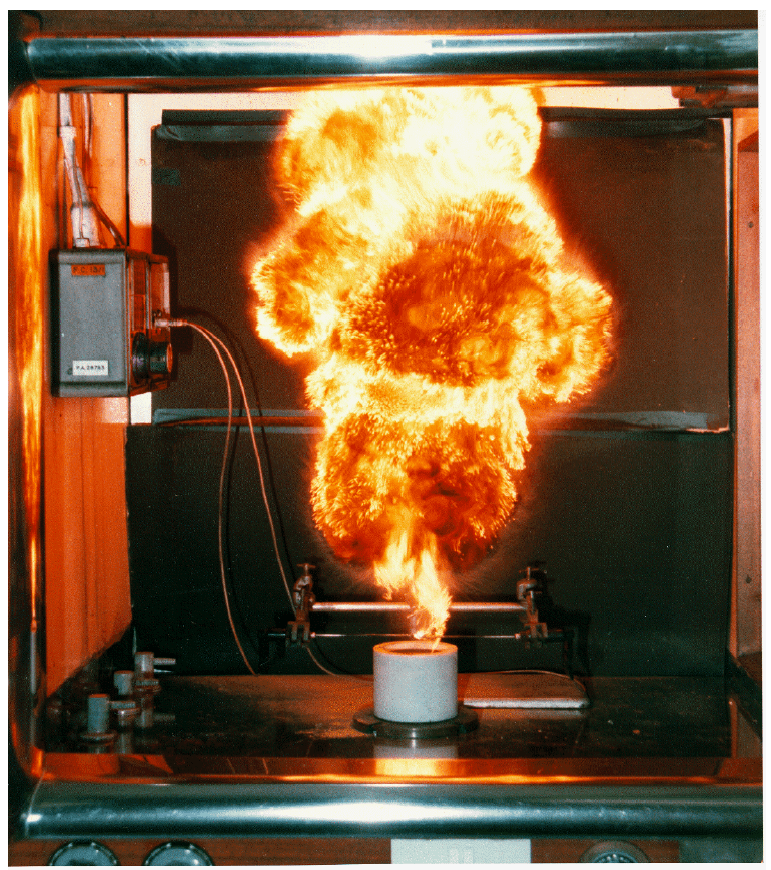

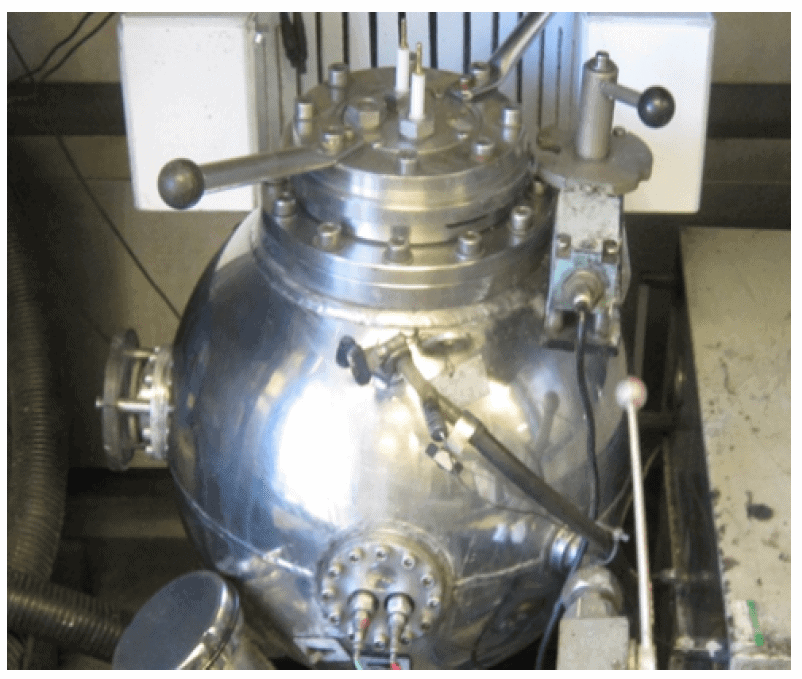

Although the methods above are relevant for prevention of flame and explosions, to confirm the quantitative assessment of a design for explosion protection you will need to conduct an actual controlled dust explosion in either the 20 litre or 1m3 test apparatus.

The dust sample is homogenously dispersed via deflector plates (typically) and ignited by a 10kJ source.

The development of the explosion pressure with time is monitored and the maximum peak pressure Pmax and maximum rate of pressure rise is obtained after a testing over a range of dust concentrations.

The peak value of the maximum rate of pressure rise (dp/dt) max is used to calculate a dust specific explosibility characteristic called Kst or Kmax = dp/dt max. V1/3

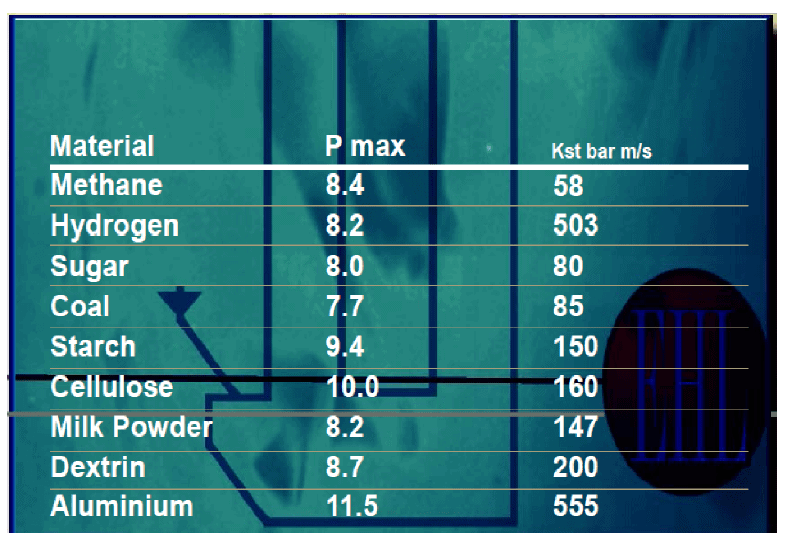

As shown, dust explosion pressures can reach the same as gases/vapours and some metal dusts can be as dangerous as Hydrogen.

Thermal Instability Testing

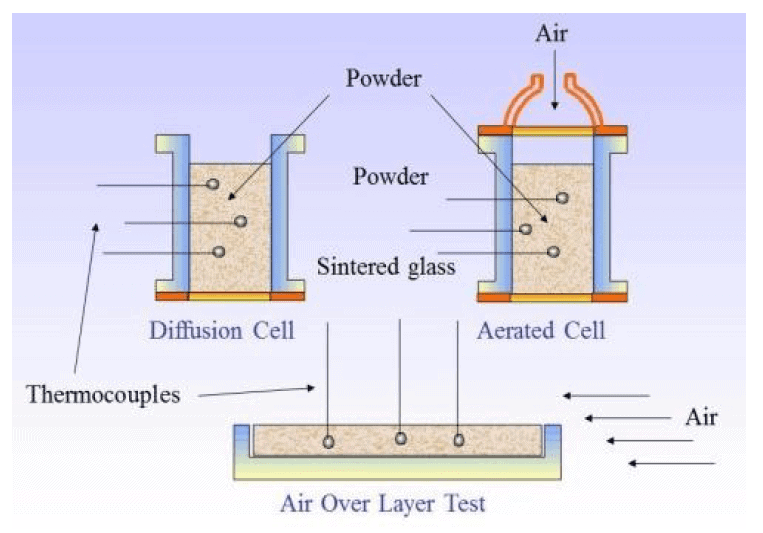

The Diffusion Cell, Aerated Cell and Layer Tests are used to assess the thermal stability of a material in bulk or layer form e.g. inside Dryers, etc. The cells are located in fan assisted ovens which can be run isothermally or in ramped mode. In addition, large scale basket tests may be required to assess the effect of scale.

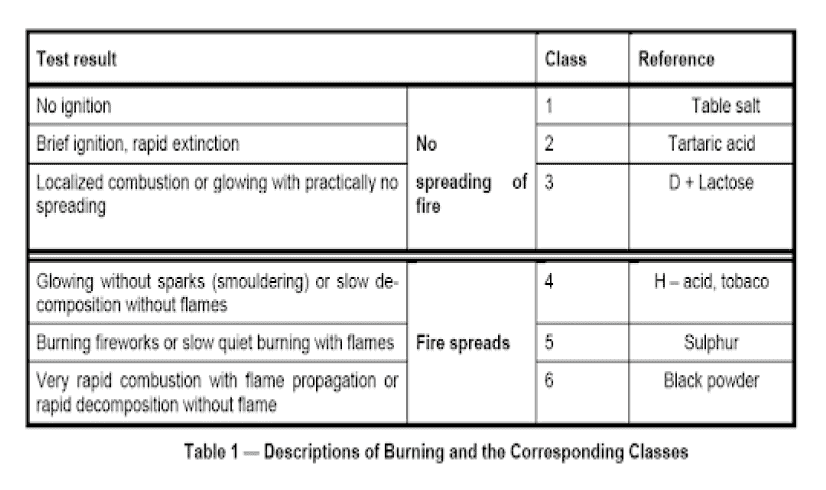

A separate Combustibility Test (comprising a train of powder ≈ 200mm long, ≈ 30mm wide and ≈ 20mm high) is used to assess the type and rate of flame/smoulder propagation along a layer of material e.g. inside ductwork, etc. It can also be used as an indicator of UN. Div. 4.1 ‘Flammable Solid’ materials for transport purposes.

The next article in this series of eight is entitled: Hazardous Area Classification. The aim of these articles is to help you establish a simple basis of safety in your plant and dispel some of the myths associated with process and safety risk assessments.

More Explosion Hazards Articles

- ATEX Safety | Establishing A Basis Of Safety In Explosive Atmospheres

- ATEX Safety | Hazardous Area Classification

- ATEX Safety | Potential Sources of Ignition

- ATEX Safety | Static Ignition & Thermal Instability

- ATEX Safety | Prevention

- ATEX Safety | Protection

- ATEX Safety | Management Procedures

EXPERTS IN EQUIPMENT FOR EXPLOSIVE ATMOSPHERES

LEADERS IN ATEX INNOVATION TO THE HAZARDOUS AREA INDUSTRIES

Thorne & Derrick are leaders in the development and distribution of Product Innovations that deliver significant improvements to clients plant, people and operational safety in the explosive atmosphere industries.

Your proactive problem solvers experienced in succession planning for the replacement of obsolete, non-conformant and legacy equipment in hazardous areas.

Your first-choice provider of innovative and competitive solutions to ensure ATEX & IECEx Compliance for Hazardous Area Electrical, HVAC & Process Instrumentation Equipment to UK and international projects.

Control Panels | Plugs | Isolators | Enclosures & Junction Boxes | Lighting | Control Stations | Motor Starters | Heat Trace | Gas Detection | Flame Detection | Process Instrumentation | Process Heating | Ventilation Fans | Security Access Control

Competitive Prices | Extensive Stocks | Technical Support | Express Delivery