Hazardous Area Air Heaters For Offshore Painting, Curing & Shotblasting

Published 04 Dec 2016

Hazardous Area Heating

- By Chris Dodds : estimated reading time 3 minutes

Safe. Reliable. Dependable.

Thorne & Derrick are specialist Hazardous Area Electrical Heating Equipment Distributors – we distribute Flameproof, Explosion Proof and Intrinsically Safe equipment for Zone 1, 2, 21 and 22 hazardous area heating.

T&D, based in the UK, service the global oil, gas and petrochemical industries with heat tracing and electrical process heating equipment.

T&D are the UK Approved Distributor for Hazloc Heaters for heating hazardous areas and in this article we focus on the significant cost-efficiencies that can be achieved by using portable electric heaters to secure faster drying times for offshore painting by increasing the ambient temperature.

Hazloc’s AEU1 Explosion Proof Air Heater is the most extensively specified hazardous area electrical air heating product to provide reliable and safe heating on offshore vessels including drill ships, jack-up vessels, semi-submersible vessels, offshore barges and floating platforms.

Offshore Painting, Coating & Shotblasting

Speeding Up Curing Times

The drying and curing time of paint coatings is affected by ambient temperature and relative humidity (RH). RH prevents paint curing effectively to offshore/marine substrates and structures such as carbon steel.

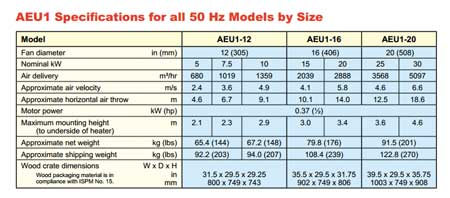

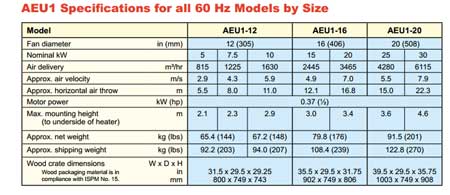

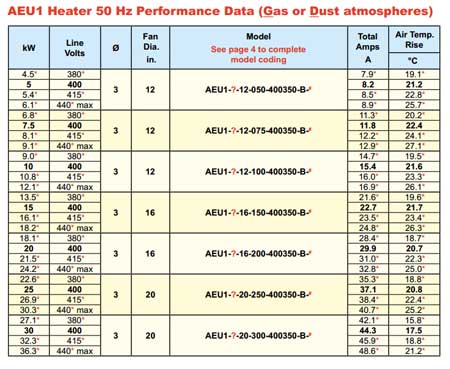

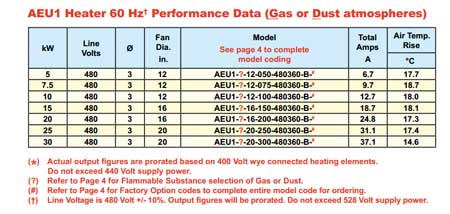

Hazloc’s AEU1 air heaters, available in both 50 Hz and 60 Hz models, are used to provide reliable and consistent ambient heating in hazardous areas Zone 1 and Zone 2 – ideal for warming enclosed workspaces which are “sheeted-off” for offshore shot blasting and industrial painting of tanks, pipework and structures.

The following table establishes the correlation between paint curing time and substrate/ambient temperatures.

Paint Drying & Curing Time

| Substrate Temperature | 5°C | 10°C | 23°C | 40°C |

| Surface (Touch) Dry | 1 hour | 45 minutes | 30 minutes | 15 minutes |

| Walk-On-Dry | 10 hours | 9 hours | 7 hours | 4 hours |

| Dry To Over Coat (Minimum) | 5 hours | 4 hours | 2 hours | 1.5 hours |

- Drying and curing times are determined under controlled temperatures and relative humidity below 85%.

- Tabled data based upon JOTUN Pioneer Topcoat technical data sheet.

Offshore Shotblasting & Painting

Designing-out risk through careful specification of electrical heating that eliminates or minimises danger is a key consideration for offshore multi-disciplined contractors.

All thought and effort is geared towards preventing sparks in explosive atmospheres.

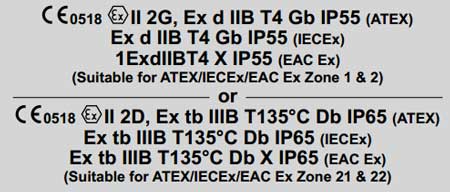

Hazloc Explosion Proof AEU1 air heater is ATEX Certified and designed to provide primary or supplementary heating for comfort or freeze protection in hazardous area (Gas or Dust) atmospheres.

Zone 1 Paint Shop Containers

This paint shop and storage container manufactured by Trans Construction AS is typically used for storing and mixing paint. The hazardous area paintshop container is insulated to A60 and fully equipped with a mixer bench, storage lockers and ventilation supply.

Hazardous Area Light, Heat & Power For Onshore Paint Spray Booths

Whether paint spraying is done in onshore booths or offshore workshops it is impossible to avoid flammable atmospheres during the spraying of flammable liquids, therefore the control of ignition sources in hazardous areas is essential. Hazardous area classification, according to European Directives such as ATEX, identify such workplace locations into Zones dependent upon the concentration and duration of flammable gas, vapour or liquid.

Electrical equipment including heaters, lighting and power distribution equipment such as plugs and sockets MUST be hazardous area certificated for location inside the spray area.

For onshore applications we can provide hazardous area fixed, portable or temporary heating, lighting and power distribution for paint spray booths, spray rooms, store rooms, drying and curing ovens.

We service both spray booth manufacturers and clients planning to retrospectively upgrade.

The EXHEAT Bulldog – safe electrical heating for hazardous area paint spray booths. ATEX certified portable heaters for dry filter extraction chambers.

Typically, onshore Paint Booths & Rooms are galvanised mild steel plenum chambers used for the application of wet spray paints such as solvent based or water based paints, lacquers and stains. The chamber works by extracting the paint overspray in to the atmosphere through an efflux cowl, via an exhaust fan and suitable filter media – paint spray booths provide separation from sources of ignition, prevent fire spread and overspray.

Conclusion

Hazardous Area Air Heaters

Significant drying time reductions can be achieved using electric heaters to improve local heating and increase the surrounding ambient temperatures – electrical heaters can be used to improve labour productivity, paint surface coverage rates and faster job completions based on an accelerated curing time of paint coatings.

Slow paint curing and drying can be overcome in protected workshop environments with potentially explosive atmospheres using appropriately certified hazardous area electrical heaters. The heater MUST only be used in atmospheres that are compliant with the hazardous area atmosphere certification – talk to us about your specific requirements.

Clearly, where multiple paint coats are required the drying time savings also multiply – contact us to discuss the benefits explosion-proof electrical air heaters provide for hazardous area heating applications.

Contact T&D, The “EX” Experts – trust us to make hazardous areas safe.

T&D supply the Offshore & Marine industries with an extensive range of Hazardous Area & Explosion Proof Equipment.

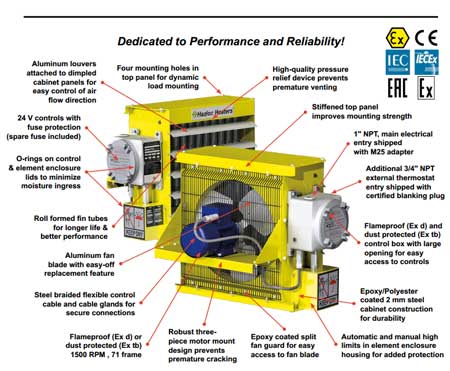

Explosion Proof Air Heaters

Hazloc AEU1

The design and dual ATEX & IECEx Hazardous Area Certification makes the Hazloc AEU1 explosion proof air heater suitable for providing air to heating oil and gas drilling rigs, petrochemical facilities, refineries, chemical storage and handling, paint storage areas, sewage treatment plants and whiskey distilleries.

Certification & Specification

Hazloc AEU1 Explosion Proof Electric Air Heaters

For Zone 1 & Zone 2 Hazardous Areas

EXPERTS IN WINTERISATION SOLUTIONS FOR INDUSTRIAL & HAZARDOUS AREA ENVIRONMENTS

Thorne & Derrick hold the largest UK stocks of frost protection & winterisation equipment to help keep your plant and personnel operational during the winter months.

Thorne & Derrick understand that prolonged periods of low ambient temperatures can bring operations to a standstill costing thousands of pounds in lost downtime.

Experts in heating solutions for use in industrial & explosive atmospheres, Thorne & Derrick have the knowledge & expertise to help clients prevent unnecessary down time this winter.

We can provide overnight delivery of Trace Heating Cables at the most competitive prices to guarantee frost protection of your pipelines and mechanical services.| Ask About Our Heat Trace Design Service.

💡 Contact us today and our skilled and friendly team can provide technical support as well as reliable, fit for purpose and compliant solutions to suit your exact requirements.

Trace Heating | Process Heating | Heating Jackets | Drum & IBC Heaters | Heated Hoses |Silicone Heating Mats

➡See our Winterisation blog TOP PICKS, including our most read articles about Trace Heating and the requirement for electrical heating products and systems to combat and mitigate Winter weather effects.

Competitive Prices | Extensive Stocks | Technical Support | Express Delivery

Further Reading

-

Hazloc Heaters AEU1 Explosion Proof Electric Heater Data Sheet

Size: 1.62 MB

Hazloc Heaters AEU1 Explosion Proof Electric Heater Data Sheet

Size: 1.62 MB

-

Thorne & Derrick Hazardous Area Brochure

Size: 883.61 KB

Thorne & Derrick Hazardous Area Brochure

Size: 883.61 KB