Hazardous Area Lighting | LED Linears Light Fittings Compared

Published 09 Jun 2020

Raytec | Hazardous Area Lighting

-

Republished with the kind permission of Raytec | LED Technology Lighting for Hazardous Areas

Hazardous Area Lighting

LED Linears Light Fittings Compared

Linear luminaires represent the most common light fixtures found in hazardous areas today.

Traditionally in hazardous area lighting, linears used fluorescent technology but more recently the trend has been to replace them with more modern LED luminaires or light fittings. The benefits of LED over traditional lighting technology are well documented and has allowed luminaires to provide a longer lifetime, reduce maintenance and improve overall performance in both industrial and hazardous area applications.

The purpose of this White-Paper, published by Raytec, is to provide an in-depth comparison of LED Linear solutions for ATEX lighting applications in potentially explosive atmospheres.

We’ll identify the most common design approaches adopted by Ex manufacturers, and highlight the impact they have on end users in relation to cost and day to day operation.

By the end, you should have a better understanding of the strengths and weaknesses of the main lighting design approaches and understand the key things to consider when specifying LED linear lighting for hazardous areas.

The design of an LED linear luminaire can generally be categorised in two ways;

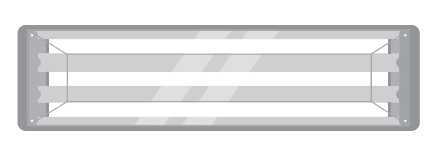

Boat Style Luminaires – the term ‘boat ‘refers to luminaires which use the same Glass Reinforced Plastic (GRP) housing as a traditional fluorescent light fitting. Their external appearance is generally identical to its fluorescent predecessor, with internal components which are modified or replaced to house LEDs in place of the old fluorescent tubes.

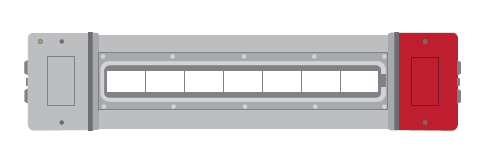

Bespoke Luminaires – these luminaires are built using a custom housing, designed around the LEDs to, in theory, deliver optimum performance. The design of the housing is not constrained by that of an existing fluorescent luminaire or light fitting.

Boat style luminaires use the same GRP housing as traditional fluorescent

Bespoke LED luminaires use a custom housing designed around the LEDs

Before we can establish if either of these design approaches provide a better overall hazardous area lighting solution, we need to look at the differences between them in more detail. To do so we will address the benefits and drawbacks of each in the context of four key areas;

- Physical Design

- Suitability to Specific Applications

- Installation

- Maintenance

Section A – Boat vs Bespoke

1. Physical Design

With the most obvious difference between the two approaches being the housing of the luminaire, we’ll start by reviewing the strengths and limitations of each light fitting.

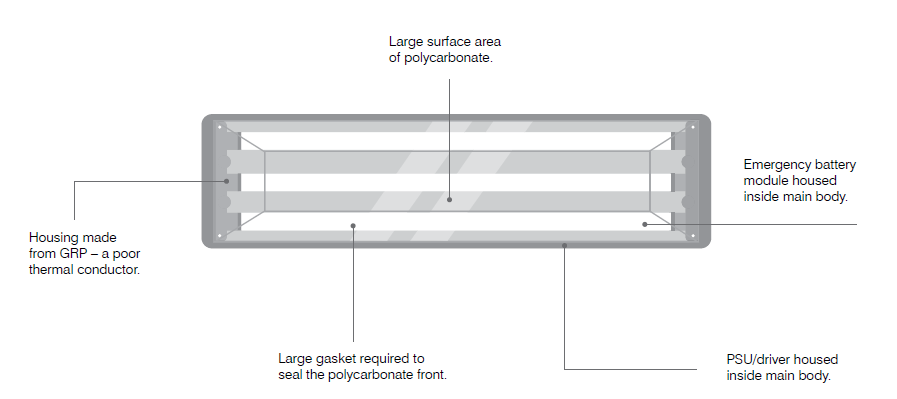

Boat Style Luminaire

A boat style luminaire is designed with a large polycarbonate lens which makes up the entire front section of the luminaire. Designed around fluorescent tubes, this large polycarbonate front was essential to maximising light output – given that the tubes disperse light 360° (i.e. they are not a directional light source).

However, removing the fluorescent tubes and replacing them with LEDs (a directional light source), means that such a large front lens is no longer required. For the majority of LED boat style luminaires, the large polycarbonate lens is a design feature which has simply been carried over from the existing fluorescent design. The drawback of this is two-fold;

- Such a large polycarbonate front makes the luminaire inherently weaker. It is more susceptible to being damaged from impact

- A significantly larger gasket is required to seal the unit. This makes the luminaire more susceptible to problems with water ingress and increases the likelihood of issues occurring on the back of any maintenance procedures which are carried out

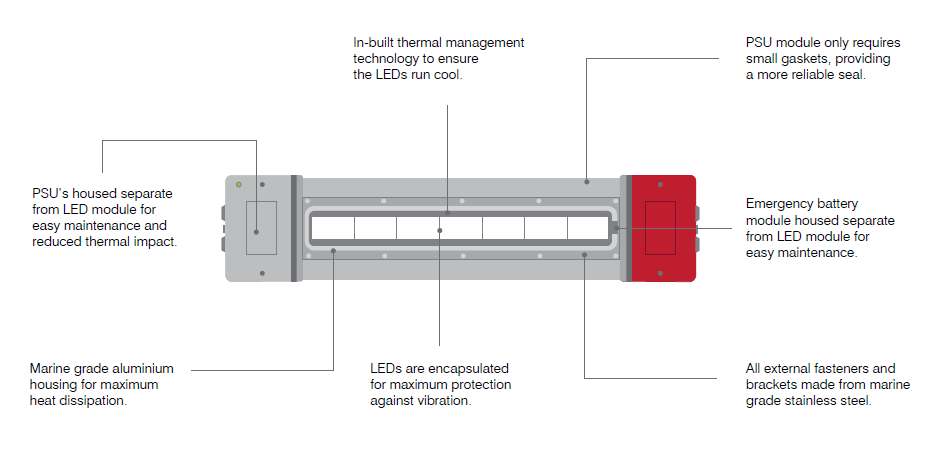

Bespoke LED Luminaire

Designed specifically to house the LEDs, a bespoke luminaire or light fitting can utilise a significantly smaller polycarbonate lens, tailored to the directional nature of the LEDs.

Manufacturers are therefore able to design them to be inherently stronger and less susceptible to damage. A bespoke luminaire can use up to 90% less polycarbonate for the front lens when compared to a boat style luminaire.

Less polycarbonate means a smaller gasket can be used.

This makes the luminaire less susceptible to issues with water ingress and reduces the chance of complications during lighting maintenance procedures. In hazardous area locations, which are often demanding environments and require robust equipment to be installed, this can be a significant advantage.

2. Suitability to Specific Lighting Applications

As well as hazardous area locations often being demanding environments, specifying lighting in these applications can also throw up specific challenges based on the conditions in which they are installed. Most commonly for Linear luminaires this includes the presence of chemicals and solvents, as well as exposure to ultraviolet (UV) light.

Depending on the materials used, these elements can attack the luminaire’s housing or cause the light fitting to degrade over a period of time.

Presence of Chemicals & Solvents

Most hazardous area Linear luminaires and lighting fittings contain materials which are susceptible to chemical attack, making them unsuitable for applications where certain chemicals or solvents are present.

Typical examples include spray booths using solvent based paints, or other applications which may simply use chemicals as part of a cleaning solution to wash down areas of the site where the luminaires are installed. As mentioned earlier, boat style luminaires tend to use a GRP housing and a large polycarbonate lens; both materials which are susceptible to chemical attack.

Although some bespoke luminaires may use an aluminium or steel housing, most will still use a polycarbonate lens.

For specifiers of lighting systems for hazardous area locations, this significantly restricts the choice of Linears that are available for these types of applications. The suitability of a specific luminaire will of course depend on the application and which chemicals or solvents are present.

For bespoke luminaires where the polycarbonate is an issue, some manufacturers may be able to offer an alternative variant fitted with a glass lens specifically for chemical applications.

UV Exposure of Light Fittings

Exposure to UV light is common when luminaires are installed in hot, sunny countries, and can cause the housing of some Linear light fixtures to degrade over time. Linears made from GRP are most susceptible. When exposed to UV for long periods, GRP can degrade and become brittle. For boat style luminaires this could cause cracks in the luminaire’s housing, or the hinges used for front internal access to snap during maintenance. Issues such as these would render the entire luminaire as useless.

While boat style luminaires exclusively use a GRP housing, some bespoke LED Linears use an aluminium or steel housing; this can overcome many of the problems associated with UV exposure. However, some manufacturers of lighting fittings for hazardous area applications may still opt to design bespoke luminaires using a GRP housing. While these luminaires may provide a low-cost alternative in applications where there is little UV exposure or risk of chemical attack, specifiers and end users should be aware of the limitations which a GRP housing has.

Pro-Tip: If installing luminaires or light fittings in a hot climate, with a high level of exposure to sunlight, avoid Linear luminaires made from GRP and specify one manufactured from aluminium or stainless steel.

3. Lighting Installation

The process of replacing or upgrading existing fluorescent luminaires to LED, also known as the ‘retrofit market’, is enormous. With so many fluorescent fittings installed worldwide, and thanks to the benefits of LED over conventional fluorescent technology, there is a real drive to upgrade and replace them. Ease of installation is critical to doing this cost effectively and should be an important consideration when specifying an ex luminaire.

Boat Style Luminaires & Lighting Fittings

With little or no change to the light fitting housing, replacing a fluorescent fitting with an LED boat style luminaire is straightforward. While there could be some variance in the fixing centres if switching between manufacturers, generally they tend to be consistent across different luminaires.

Some manufacturers that have an existing range of fluorescent luminaires also offer an upgrade kit. This allows an end user to retain the same housing and fit a new LED module to replace the existing fluorescent tubes (and any corresponding control gear).

For lighting manufacturers who have previously sold fluorescent fittings this makes commercial sense – given that selling a lighting upgrade kit is likely to increase their chance of being able to retain business from existing customers who have previously installed their fluorescent products.

But is this the fastest, most cost-effective method?

While some kits are easy to replace, it does vary between manufacturers and some are more complicated to fit than others. Carrying out this kind of maintenance work at height, while the luminaire is installed, may also be problematic.

End users should review what the process of installing the kit involves; in some cases, it might actually be easier to replace the whole light fitting.

Bespoke Luminaire Installation

So long as they are operating within the constraints of the Ex certification, manufacturers effectively have carte blanche when designing a bespoke LED Linear. Unlike the boat style luminaires we have discussed, manufacturers are not constrained by an existing housing, or by the materials that can be used.

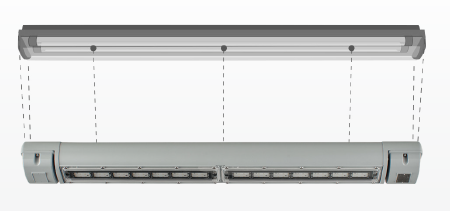

However, for retrofit jobs (where existing fluorescent luminaires are being replaced with LED Linears), specifying a light fixture which matches the dimensions and specifications of the existing fluorescent is critical to keeping installation costs down.

For this reason, lighting manufacturers should limit any ‘design flare’ regarding the physical shape and size of the luminaire.

Retaining the same dimensions, cable entries and fixing centres as conventional fluorescents will mean an end user can still use the same cables, glands and bracketry. This could make the installation process significantly easier and more cost effective. This is an area we will cover in more detail during Section B of the White-Paper.

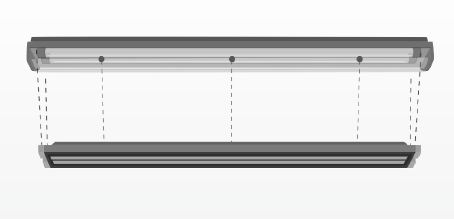

Fitting an LED module inside an existing GRP fluorescent housing

Replacing an existing fluorescent fixture with a bespoke LED luminaire

4. Hazardous Area Lighting Maintenance

Opting for LED will help to reduce the amount of maintenance required to the Linear luminaire over its lifetime, but as with any electrical product, there is always some risk of failure which requires maintenance to be carried out. In hazardous area applications, where the environment can be particularly harsh and challenging, this risk is often amplified.

Specifying a luminaire or light fitting which helps to make maintenance easier in hazardous areas can therefore provide significant costs savings.

Hazardous Area Lighting Maintenance by Design

The design of a boat style luminaire, and its large polycarbonate front cover (which generally opens on a hinge for internal access), means that all control gear must be housed inside the main body of the luminaire.

For maintenance purposes, access to the LED module should be relatively straightforward, but maintenance to other components (such as replacing drivers or emergency batteries) could be more complex if the gear tray must be removed in order to access them.

This is especially true when the luminaire is still installed and the person carrying out the lighting maintenance is working at height; it could lead to components, or fixings, falling and being lost or damaged.

Thanks to the greater level of flexibility a lighting manufacturer has when designing a bespoke LED linear, these luminaires are not restricted to locating all control gear within the main body; a bespoke luminaire can be designed to be more maintenance friendly.

SPARTAN Linear is a good example of this; with the PSU’s housed in the luminaires’ end caps, they can be removed using just two M6 bolts and swapped out in just a couple of minutes. The end cap covers are also attached using a small retention clip; meaning there is no risk of the PSU module falling while maintenance is being carried out at height.

However, not all bespoke luminaires are necessarily easy to maintain. It will depend on how the luminaire has been designed and whether maintenance has been prioritised during the design phase. This is something we will focus on in Section B.

Micro-Switches

Boat style luminaires tend to feature a micro-switch which turns the lighting module on/off when the housing is opened or closed; all other control gear remains live. The micro-switch is another feature which has been carried over from traditional fluorescent fittings.

Because fluorescent tubes needed to be replaced frequently, the micro-switch would make the process of re-lamping faster and easier.

However, with an LED luminaire there is no need for re-lamping. For all intents and purposes this makes a micro-switch on an LED Linear an unnecessary feature with no tangible benefit to the end user. While it could be argued that it has no detrimental impact, it does add unnecessary cost to the build which is likely to be passed on to the customer. In contrast, a bespoke luminaire is designed from the ground up, specifically for the LEDs.

5. Boat vs. Bespoke Light Fittings : A Summary

Having covered ease of maintenance, installation and durability, as well as highlighting some of the strengths and weaknesses of the two main design approaches, we can conclude that;

- Bespoke LED luminaires can be designed from the ground up to get the optimum performance from the LEDs. They are not restricted to using an old style of housing in the same way a boat style luminaire is.

- With the ability to use more robust and durable materials, bespoke LED luminaires can be more suited to demanding applications, such as those with high levels of UV exposure. Boat style luminaires are inherently weaker due to their large polycarbonate front and GRP housing.

- Bespoke luminaires which are designed to retrofit existing fluorescent fittings can be just as easy to install as a boat style luminaire.

Accessing the internal components of a boat style luminaire can be challenging, whereas a bespoke luminaire, designed with maintenance in mind, makes servicing easier.

We can therefore conclude that a bespoke LED Linear provides the best long-term solution for an end user. The main benefits of opting for a boat style luminaire are to the manufacturer; modifying an existing fluorescent fitting being an easy method of developing, certifying and launching an LED luminaire.

For end users though, the decision to upgrade to LED is likely to be based around performance and long life, and they should also give consideration towards ease of maintenance, installation, and durability. With this in mind, a bespoke LED linear can offer many advantages.

However, the advantages of a bespoke LED luminaire are only relevant when the manufacturer has given these areas proper consideration during the design process, i.e. so it is easy to install, maintain and uses materials which are suited to demanding environments. Not all are equal. Section B of this White-Paper will therefore focus on how to pick the right bespoke luminaire, and the key features and specifications to look for.

| Bespoke LED Linear | Boat Style LED Linear | |

| Physical Design | ✓ Can be designed to be robust and suited to demanding applications | X Inherently weaker due to large areas of GRP and polycarbonate |

| Suitability to Specific Applications | ✓ More flexibility in the choice of materials which the luminaire can design with | X Restricted in choice of materials – unsuitable to applications at risk of UV exposure or chemical attack |

| Installation | ✓ Can be designed for easy installation – but always check with the manufacturer | ✓ Based on an existing fluorescent and should be easy to replace |

| Maintenance | ✓ Manufacturer has more flexibility to design the luminaire to be easy to maintain | X All components housed within main body, which can restrict access to some components |

Lighting Diagrams: Boat v Bespoke Light Fittings

Boat Style Housing Features

Bespoke Housing Features (based on SPARTAN Linear WL84)

Section B – Choosing the Right Bespoke LED Luminaire

Having compared the different types of luminaires available in Section A, we established that a bespoke LED luminaire provides the best solution for an end user, providing it has been designed in the correct way – this is the crucial bit. Because there are fewer design restrictions, manufacturers can apply their own ideas and interpretations.

This has led to a range of bespoke LED Linear solutions on the market which are vastly different. To help you when choosing an LED Linear, in this section we’ll focus on three important areas to assess prior to specifying; ease of maintenance, ease of installation, and emergency performance.

1. Lighting Maintenance – Go Modular

How do you identify whether your bespoke luminaire is easy to maintain or not? It all depends on how much importance a manufacturer has attributed to future maintenance during the design of the luminaire. In simple terms, a manufacturer can use one of two main methods when designing a luminaire, and it has a significant impact on how easy it is to maintain.

Sealed for Life

A luminaire or light fitting which is ‘sealed for life’ restricts the level of maintenance which can be carried out on-site. The luminaire is factory sealed (or encapsulated), primarily as a method of protection (as part of the luminaires hazardous area certification). Once the luminaire is sealed, it cannot be re-opened and internal components cannot be accessed without invalidating the Ex certification.

Should a problem occur, such as a failed PSU (power supply unit), because the luminaire is sealed there is unlikely to be anything that on-site engineers can do to rectify the problem. The luminaire must therefore be returned to the manufacturer for repair.

As well as being environmentally irresponsible, the end user could also be left without light which will have consequences for the safety and security of that area of the site.

Modular Luminaires

Luminaires which are designed with maintenance in mind can be referred to as ‘modular’. Components of a modular Ex luminaire are interchangeable, meaning spare parts can be kept on-site to service the unit. This can be achieved because the luminaire does not rely on being factory-sealed to achieve its hazardous area rating.

A modular luminaire will allow the engineers on site to change key components, such as the PSU, in a matter of minutes. This allows light to be restored quickly and down-time to be minimised. Ultimately, a luminaire that has been developed with maintenance in mind will reduce long-term costs.

Pro-Tip – Identifying easy maintenance;

- Ensure PSUs, emergency batteries and other serviceable parts can be accessed easily, quickly, and without the need for specialist tools.

- Ensure spare parts are available from the manufacturer and can be stocked on-site if requested

2. Lighting Installation – Use A Retrofit

In Section A, we identified that bespoke LED luminaires can be just as easy to install as a boat style luminaire, providing they have been designed as a retrofit to existing fluorescent luminaires. This means using the same general dimensions, cable entries and fixing centres. Let’s look at these elements in more detail;

- Dimensions – if the new luminaire is the same length as the existing fluorescent fitting, the end user should be able to utilise existing cables. Specifying a smaller luminaire could mean the existing cable layout is no longer suitable, and new cable would likely be required throughout the installation. Look for a luminaire which is 600mm/2ft in length when replacing 2x18W fluorescents, or 1200mm/4ft in length when replacing 2x36W fluorescents

- Cable Entries – specifying a luminaire with the same sized cable entries will allow the existing cable glands to be used. Specifying a luminaire with different sized entries will mean the existing glands will no longer be suitable. While gland reducers or adaptors could help in some cases, it will result in additional expense to the overall installation. Because entry size can vary between regions, manufacturers should offer the luminaire with a range of different sizes to suit different applications.

- Fixing Centres – on conventional fluorescent fittings, the fixing centres used to mount the luminaire are generally consistent across different manufacturers; M8 (or sometimes M6) threaded holes, with a 400mm spacing between mounting centres for 2x18W fluorescents, and 700mm spacing for 2x36W fluorescents. If the fixing centres of the new LED fitting match these specifications, the existing bracketry can be used.

Failure to match your new luminaire to any of these three specifications and you could be faced with a sizeable cost to supply new brackets, cables or glands.

Pro-Tip: To reduce time and cost of installation, a true retrofit solution should use the same dimensions, fixing centres and gland entries as traditional fluorescent fittings.

3. Emergency Lighting Performance in Hazardous Areas

Emergency Ex lighting plays an important role in maintaining safety in hazardous locations and the well-being of those who work in them, providing back-up illumination when the primary power source fails. However, with a range of emergency luminaires on the market, each provide different levels of power when in emergency mode.

The most common way of measuring emergency performance is by looking at both duration (how long it provides back-up illumination for) and percentage output (the level of illumination the luminaire provides in emergency mode compared to normal operation).

Output and duration are always a trade-off. Generally, the higher the output, the shorter the duration will be. A duration of 3 hours is commonplace in order to meet regulations relating to emergency lighting, but the percentage output which manufacturers offer will often vary significantly – in some cases dropping significantly in order to achieve the 3-hour duration.

The impact of specifying emergency luminaires for hazarodus area lighting which have a lower percentage output could be that;

- Light levels in emergency scenarios are below minimum lux requirements. This would put workers at risk during emergency conditions

- More emergency luminaires are required to achieve minimum lux levels

The capability of the emergency luminaire largely depends on the size and specification of the battery which is used.

Larger, higher specification batteries provide higher output and longer duration, but also come at greater cost.

For hazardous area lighting manufacturers looking to keep costs down, the obvious way around this is to use smaller batteries and reduce the percentage output in emergency mode. However, from an end user’s perspective this could drastically increase costs as more emergency luminaires will be required to hit the target lux level.

To avoid any surprises following installation, always check the duration and percentage output of an emergency luminaire.

Where possible, it’s also advised to perform a full hazardous area lighting design for both standard and emergency operating conditions.

Raytec Lighting Design Service

A free lighting design service brings any project to life, providing a visual representation of what the final installed lighting solution will look like.

Intelligent Emergency

Another feature to look out for when specifying an emergency luminaire are intelligent systems, such as SPARTAN Intelligent Emergency, which help to increase the ease of inspection and automate testing procedures.

To operate effectively, an emergency luminaire’s battery must be regularly checked and tested to ensure there is no degradation in its capacity. Further conditioning is also required to maintain its optimum performance.

SPARTAN Intelligent Emergency luminaires feature an in-built microprocessor which automatically cycle the emergency batteries, checks the health status of the luminaire, and communicates the information via an LED indicator.

In contrast, conventional emergency luminaires rely on human intervention for the process of routinely monitoring, checking and testing the luminaire, meaning there is also an associated risk of human error or neglect. If the luminaire is not properly tested and maintained, there could be serious implications on the performance of the luminaire when an emergency situation arises.

This could lead to safety issues on-site. Automating the process, by introducing intelligent emergency luminaires, effectively eliminates this risk; increasing reliability of the emergency network and improving overall site safety. This also means a reduction in the time and cost of maintenance, given the elimination of human inputs to the maintenance process.

Pro-Tip: Intelligent emergency solutions help to improve on-site safety, while reducing the time and cost associated with inspecting and testing Ex luminaires.

Summary

To recap, in order to make the most of the benefits which upgrading to LED offers, end users should specify a luminaire which has been designed around the LEDs, using a custom housing which allows performance to be optimised.

However, beyond this end users also need to ensure they are specifying a luminaire which has been designed (from an installation perspective) to easily replace conventional fluorescent fittings, is easy to maintain, and (when required) provides an effective emergency option which can reduce costs and increase safety using intelligent, automated testing procedures.

Follow this general rule of thumb when specifying Linear luminaires for your lighting installation, and you’ll achieve a solution which delivers the best performance and reduced long terms costs.

Specifying an LED Linear – The Key Features to Look For

- A housing which is built around the LEDs, ideally with a material which is a good conductor of heat

- If upgrading from fluorescent, a luminaire which has been designed to allow easy installation with the same dimensions, fixing centres and cable entries

- Ensure the luminaire can be maintained on-site and will allow light to be restored quickly, easily, and affordably in the event of any failures

- Ensure the emergency output levels will provide adequate lux levels for emergency scenarios

EXPERTS IN EQUIPMENT FOR EXPLOSIVE ATMOSPHERES

leaders in ATEX Innovation To The Hazardous Area Industries

Thorne & Derrick are leaders in the development and distribution of Product Innovations that deliver significant improvements to clients plant, people and operational safety in the explosive atmosphere industries.

Your proactive problem solvers experienced in succession planning for the replacement of obsolete, non-conformant and legacy equipment in hazardous areas.

Your first-choice provider of innovative and competitive solutions to ensure ATEX & IECEx Compliance for Hazardous Area Electrical, HVAC & Process Instrumentation Equipment to UK and international projects.

Control Panels | Plugs | Isolators | Enclosures & Junction Boxes | Lighting | Control Stations | Motor Starters | Heat Trace | Gas Detection | Flame Detection | Process Instrumentation | Process Heating | Ventilation Fans | Security Access Control

Competitive Prices | Extensive Stocks | Technical Support | Express Delivery