Heat Tracing Cables For Pipework Frost Protection By Eltherm

Published 02 Feb 2021

Eltherm Heat Tracing Cables – Frost Protection For Pipework Can Be Used in Hazardous & Non-Hazardous Areas

- By Chris Dodds : estimated reading time 5 minutes

➡ Please note that this blog article was originally written in 2017 and was correct at the time of publish

Winter wreaks havoc and inflicts damage to process plant equipment, pipework and vessels every year if an adequate preventative maintenance plan is not in place – it is not unreasonable to expect freezing temperatures, wind chills and seasonally cold weather from October to March in the UK.

Add on the strength of the wind and it will feel bitter for many of us today, so you will need that extra layer ❄️ pic.twitter.com/C0nqGf8yVw

— Met Office (@metoffice) January 26, 2017

What often catches plant managers and operations out however, is not simply that exposed areas of pipework can freeze if not suitably trace heated and insulated using heat tracing cables, but actually that the more extreme weather has a physical effect on products within process equipment.

For instance, drum heaters can be deployed to provide viscosity maintenance to prevent drum contents from freezing, provide heat-up and high temperature process heating.

Heat Tracing Cables For Pipework Protection

Against Freezing Temperatures

For many products, colder temperatures will also mean higher viscosities and whilst a well specified trace heating solution would normally cater for this and regulate working temperatures thermostatically, it is often overlooked that extreme cold snaps can actually mean that the watts per metre of heating power installed maybe insufficient to maintain a higher temperature (perhaps of 30°C or more) against an extremely sharp fall in ambient temperatures, unless this is considered up-front.

During the winter of 2010, temperatures of -17°C were recorded in parts of the UK.

Eltherm Heat Trace Frost Protection

Whilst a conventional frost protection set-up can prevent water pipes from freezing, process lines operating at higher temperatures can become blocked causing overworking to pumps and resulting in the product under process not being manufactured to sub-standard with an under-powered system.

To counter this, the process temperature should always be stated upfront and used in heat-loss calculations and not simply the frost protection level of +5°. This may sound an obvious statement, but often heat tracing installations are sub-contracted to third parties to resolve, with the ensuing ‘Chinese Whispers’ scenario resulting in a defacto frost protection solution being arrived at.

Heat Tracing Cable

Eltherm Self-Regulating Key Features

- Self-regulating heat tracing cable with adaptable output

- A wide range of temperature applications

- Demand orientated output grading

- High chemical resistance for hazardous area heating

- No temperature limitation required

- Simple to lay and install and can be cut to length

- Connection with plug-in connectors

Self regulating heat tracing cables have become the cornerstone of Winterisation systems in recent years and if specified correctly will provide an effective and energy efficient solution to frost protection as well as process temperature maintenance applications in industrial and hazardous area heating requirements – it is crucial to understand that the heating cable power output decreases as the ambient temperature rises, this is the “intelligent cable” concept of self-regulating cables.

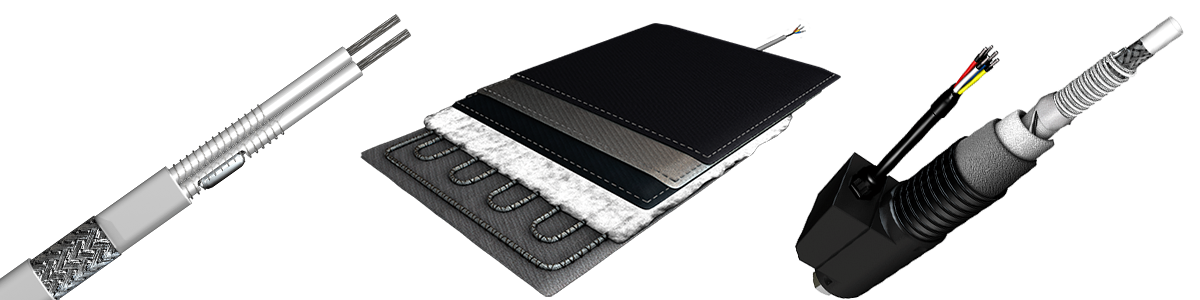

Eltherm – Heating Cables, Surface Heating Mats & Heated Hoses

Heat Tracing Cables

Frost Protection & Hazardous Area Heat Tracing

The self regulating characteristic will mean that the power output at the intended temperature is somewhat less. It’s vital that the manufacturers trace heating cable datasheets are referred to and that the output for the trace heater cable is selected based upon the target maintain temperature and not the ambient temperature.

Another misconception is that self regulating heat tracing cables will automatically maintain a sensible frost protection level. It may well materialise this way under certain circumstances but a correctly set thermostatic line sensing controller is important to prevent water and other products in pipes from overheating.

Even a 10 watts per metre heat tracing cable if incorrectly specified can spell trouble on small pipes. For plastic pipework, we would always recommend remaining below 20W/m, whether thermostatically controlled or not. Simply put, when the trace heating cable is energised, depending on the level of the thermal insulation and the current temperature of the pipe contents, it’s not impossible to weaken pipes made from lower melt temperature plastics, for example PVC pipes.

Conversely, plastic pipes do not transfer the heat from a trace cable efficiently therefore heating cables should be over-wrapped with aluminium foil tape to improve heat dissipation to the pipework.

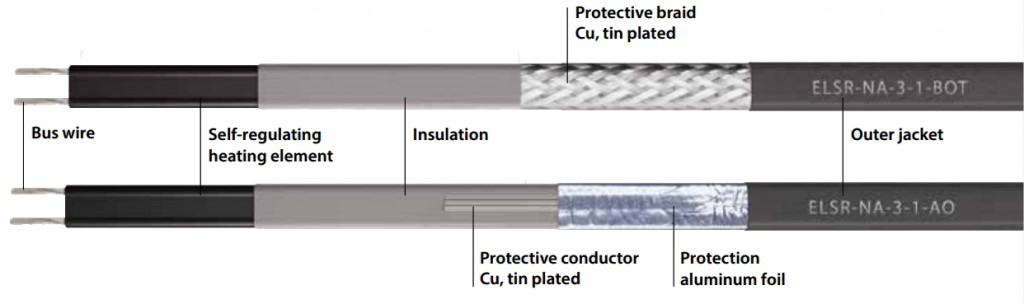

Eltherm Self-Regulating Heat Trace Cable Components

The Electrical Heating Package

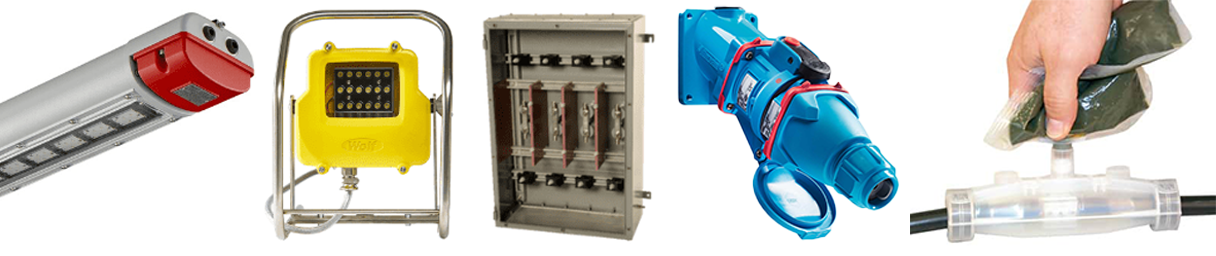

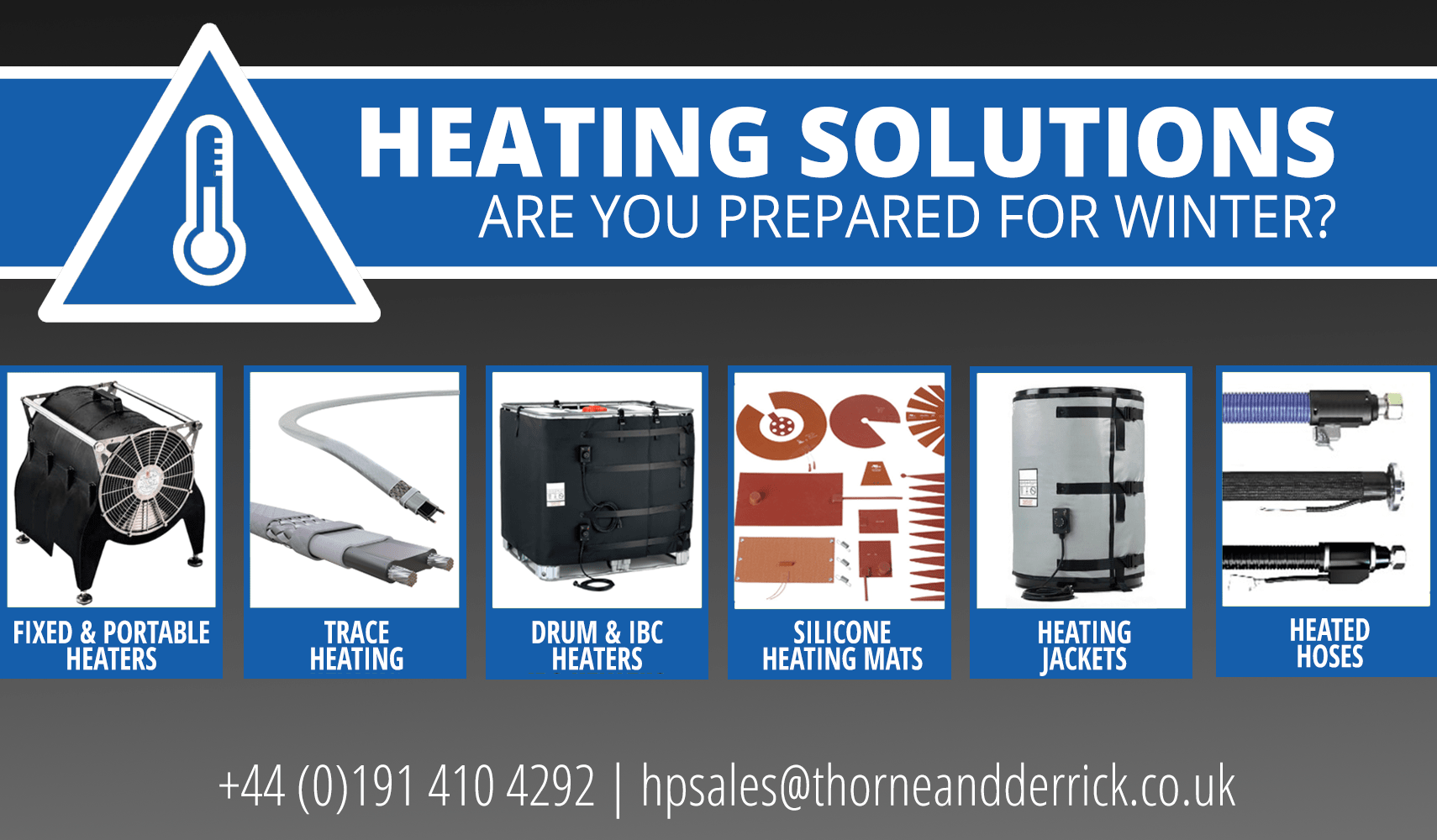

Thorne & Derrick provide a complete portfolio of Electric Process & Trace Heating Solutions for Industrial, Hazardous Area & Explosive Atmospheres,

- Trace Heating Systems & Cables

- Serial Resistance Trace Heaters

- Parallel Resistance Trace Heaters

- Self-Regulating Parallel Trace Heaters

- Mineral-Insulated Trace Heaters

- Commercial |Ramp Heating & Gutter Heating

- Industrial | Explosive Proof ATEX & IECEx Certified for Hazardous Areas

- Zone 1 & 2 (Flammable Gas) or Zone 21 & 22 (Combustible Dust) | Class I, Division 1 & 2

- Process Heating

- Air, Immersion & Line Heaters

- Heated Hoses – Analytic & Pressure

- Heating Mats & Jackets

- Drum, IBC & Container Heaters

Specialist Distributors of Electrical Heating, Lighting, Power & Process Instrumentation Equipment to deliver significant safety and reliability improvements in the Industrial, Explosive Atmosphere & Energy sectors.

Your proactive problem solvers experienced in succession planning for the replacement of obsolete, non-conformant and legacy equipment in hazardous areas with ATEX & IECEx Certification & DSEAR Regulatory Compliance.

Industries Supplied | Process, Oil & Gas, Petrochemical, Utility (Water, Gas & Electricity), Food & Beverage, Pharmaceutical, Renewable, Rail, Datacentre, Battery Storage

Product Categories | Electric Heating | Lighting | Control Panels | Confined Space Safety | Plugs & Sockets | Isolators | Enclosures & Junction Boxes | Control Stations | Motor Starters Gas Detection | Security Access Control | Duct Seals | Cable Accessories LV HV | Earthing & Lightning Protection | Feeder Pillars | High Voltage Electrical Equipment | Joints Terminations Connectors MV HV