Heated Hoses | Temperature Maintenance In Hot and Cold Bitumen Processes In Industrial & Hazardous Areas

Published 20 Jan 2021

Temperature Maintenance In Hot and Cold Bitumen Processes In Industrial & Hazardous Areas

Heat Tracing Cables By Eltherm

Frost Protection For Industrial & Hazardous Areas Available From Stock At T&D

In the seventh of this blog series by Eltherm they will discuss the best electrical trace heating system including heated hoses will ensure temperature maintenance and freeze prevention to keep Bitumen flowable at 180ºC.

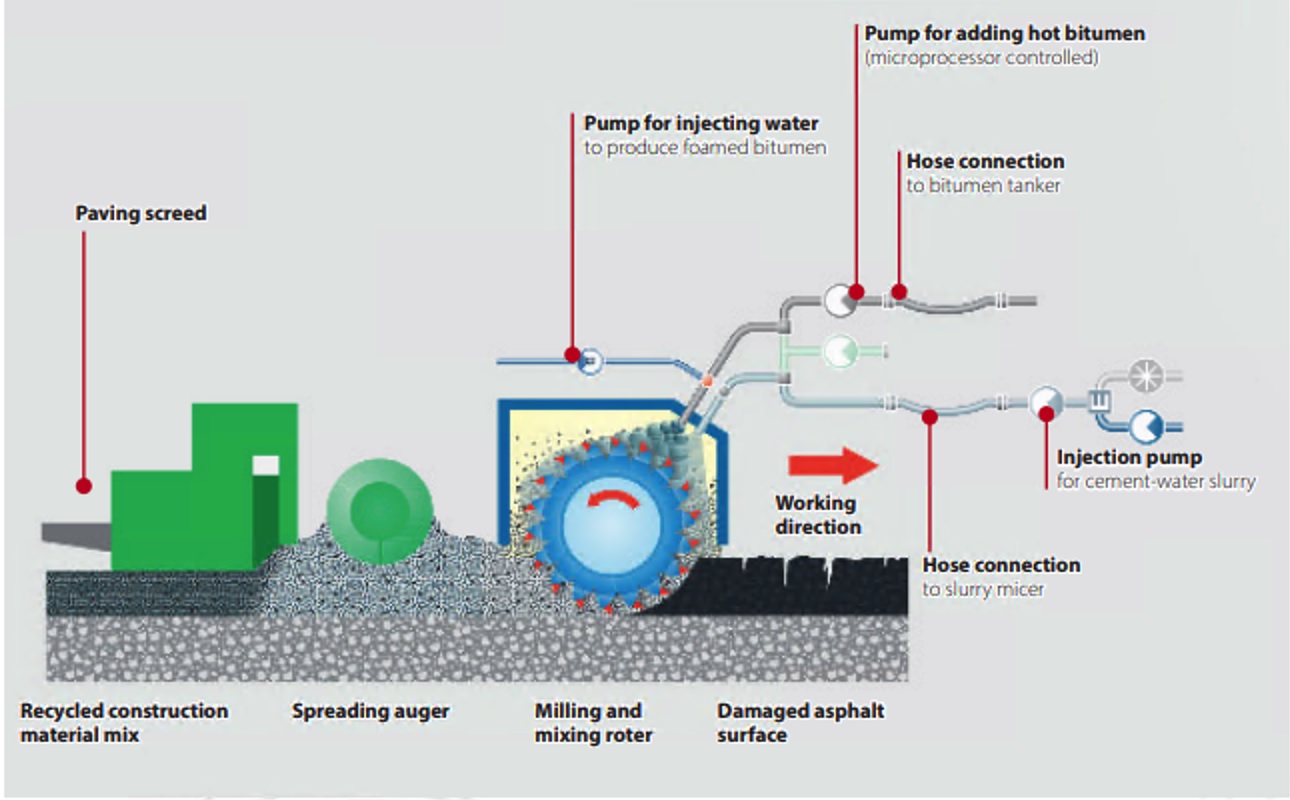

Cold recyclers are used to skim the old road surface and apply a new surface simultaneously. The skimmed material is then recycled. To achieve a homogeneous surface finish, hot Bitumen is added to the process. b Due to the varying width of the working surface, the feeder hoses need to be flexible and up to 5 m long.

Keeping Bitumen Flowable at 180°C

Bitumen is used in road construction for asphalt overlays and to repair road damage. It is also used in joint and sealing technology for concrete and asphalt surfaces. Hot asphalt installation is a highly automated process in which heated pressure hoses are used to keep the bitumen at 180 °C. Without heat tracing, bitumen would loose its flowability and pumpability, causing damage to machines, pumps and dispensers.

Heated Pressure Hoses Advantages

- Reliable temperature maintain to safeguard specific properties such as bitumen flowability (viscosity)

- Flexibility and yet robust in tough industrial use

- Reliable protection against condensation

- Long-term reliable function

- Resistance to aggressive product components

- Long-term reliable function

- Low maintenance, reduced down times

Heated Pressure Hoses in Bitumen Applications

- Pipelines that carry bitumen

- Storage tanks and containers for bitumen

- Containers for transporting bitumen

- Flexible heated hoses for transporting bitumen from storage to dispensing

- Temperatures: 160 to 250 °C

Related Applications

- Hotmelt glue systems

- Filling machine

- PUR foam machine

- Processing of heavy oil

- Dosing and spray-painting machines

Heated pressure hoses serve to maintain a constant temperature for transporting oil, grease, wax, resin, tar, paint, water, glue, plastics or casting compounds. The heated hose is implemented in machines and robotic systems.

Schematic view of a bitumen processing unit

Thorne & Derrick specialise in providing specialist heating for industrial and hazardous areas including Eltherm’s heat tracing cables and heated hoses.

ELTHERM INDUSTRIAL & HAZARDOUS AREA HEATING

Eltherm heating products provide freeze protection, temperature maintenance and temperature control ranges of up to 1000°C and are used in many industries and applications from oil and gas to utilities and power generation. Eltherm products are manufactured to the highest hazardous area specifications including ATEX and IECEx for heating pipes, hoses, drums, vessels and IBC’s.

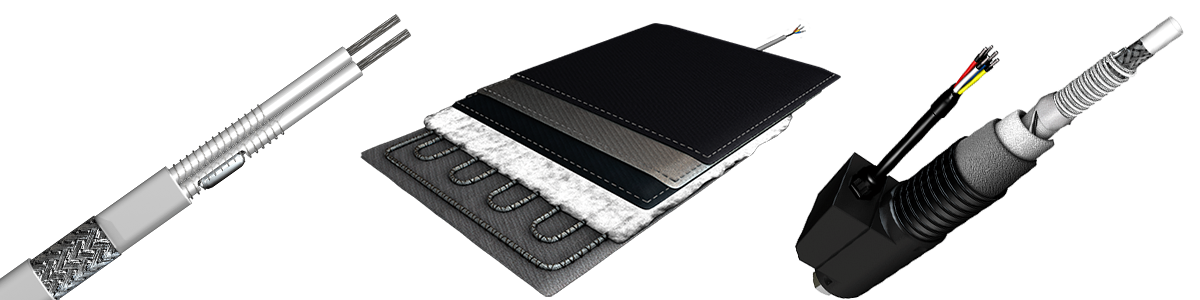

Eltherm self regulating heat trace cable provides frost protection and maintains product viscosity in pipes, tanks, drums and vessels

Electrical Heating Specialists

Thorne & Derrick International, based in the UK, can specify and supply from stock an extensive range of Electrical Heating Equipment for industrial and process heating applications – this includes temperature maintenance and frost protection (Winterisation) products for pipework, valves, IBC’s, drums, hoses, tanks and vessels. We produce custom silicone heaters for rapid and high temperature heat-up of complex shapes and surfaces – from concept, design to the delivery of standard or bespoke heaters on the shortest lead times. From the largest UK heat tracing cable stocks we deliver Electric Trace Heating Systems for pipework frost protection, ramp heating, roof/gutter snow melting and de-icing – enquire about our in-house design service.

Further Reading : Winterisation | Electrical Heating Solutions to Overcome Cold Climate Challenges

EXPERTS IN WINTERISATION SOLUTIONS FOR INDUSTRIAL & HAZARDOUS AREA ENVIRONMENTS

Thorne & Derrick hold the largest UK stocks of frost protection & winterisation equipment to help keep your plant and personnel operational during the winter months.

Thorne & Derrick understand that prolonged periods of low ambient temperatures can bring operations to a standstill costing thousands of pounds in lost downtime.

Experts in heating solutions for use in industrial & explosive atmospheres, Thorne & Derrick have the knowledge & expertise to help clients prevent unnecessary down time this winter.

We can provide overnight delivery of Trace Heating Cables at the most competitive prices to guarantee frost protection of your pipelines and mechanical services.| Ask About Our Heat Trace Design Service.

💡 Contact us today and our skilled and friendly team can provide technical support as well as reliable, fit for purpose and compliant solutions to suit your exact requirements.

Trace Heating | Process Heating | Heating Jackets | Drum & IBC Heaters | Heated Hoses |Silicone Heating Mats

➡See our Winterisation blog TOP PICKS, including our most read articles about Trace Heating and the requirement for electrical heating products and systems to combat and mitigate Winter weather effects.

Competitive Prices | Extensive Stocks | Technical Support | Express Delivery