How Changing To Wolf Airlamps Significantly Reduces Downtime At US Mine

Published 24 Sep 2019

How Changing To Wolf Airlamps Significantly Reduces Downtime At US Mine

-

uploaded by Chris Dodds - Sales & Marketing Manager Thorne & Derrick

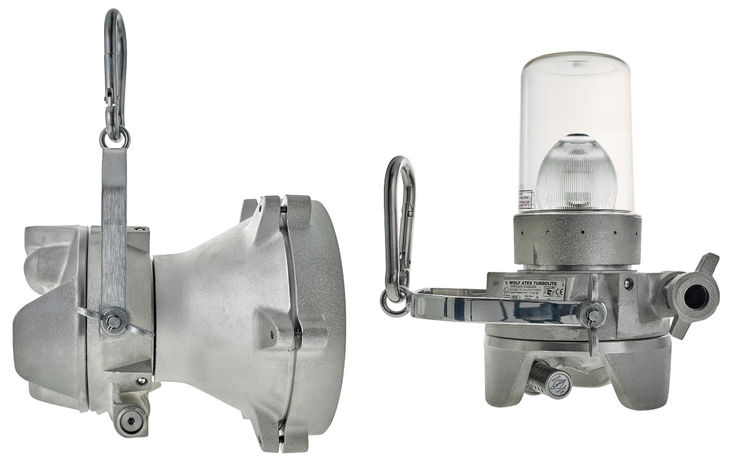

Wolf Airlamps

ATEX Turbolite

T&D are Main Distributors for Wolf Hazardous Area Lighting – this includes the complete range of hazardous area Wolf Airlamps forming part of their portable and temporary lighting range. The airlamps are certified according to ATEX for safe use in hazardous areas Zone 1 & Zone 2 (Gas) and Zone 21 & Zone 22 (Dust).

“Changing from electric lights to Airlamps has reduced downtime and increased efficiency at the mine substantially.” Jim Reeves, Safety Lamp of Houston.

Climax Molybdenum Co, is part of Freeport-McMoRan, one of world’s largest molybdenum producer and supplier. Molybdenum is a silvery-white metal that is ductile and highly resistant to corrosion.

They have a mine in Henderson, Colorado where they extract and transport Molybdenum by conveyor system 15 miles through the mountain to the mill for processing. Molybdenum is used in a variety of metallurgical and chemical products.

Electric cables coming from the main shaft and through to electric lights used to illuminate the tunnels for mucking operations. Unfortunately the electric cables were often damaged causing the lights to no longer work resulting in delays in production time and costly replacements using expensive copper wire.

Safety Lamp of Houston (Wolf Safety’s partner in USA) were approached by Climax Molybdenum Co to find a more cost effective solution to the problem

Safety Lamp of Houston decided on the Wolf Turbolite airlamps providing a reliable and versatile hazardous area lighting solution – a high powered compressed air driven lamp with a light output of up to 9,000 lumens.

Hooks are also present so the airlamps can be screwed onto or suspended from the roof of the tunnels, attached to a folding tripod and plugged in to the supply hose. The hose doesn’t need to be removed during blasting and if it does get cut jointing back together wouldn’t take long at all eliminating expensive production downtime.

Wolf ATEX Turbolites

One issue that could be encountered is the risk of condensation which is caused by the air compressing at 12,000 feet and sending it down metal ductile pipes for nearly a mile into the ground where the temperature is as cool as 10°C which has the potential to cause rust and risk damage to the light.

The problem was combated by installing a double filter unit to each lamp between the connection to the light and connection to air hose. When the bulbs are replaced this is the perfect opportunity to clean the filters. As new operations were opened up, the ATEX Turbolite, which has a sealed bearing, was purchased and used to further reduce the risk of rust and extend the life of the lamp.

The Climax Henderson mine continues to use Wolf Airlamps and since 2009 has purchased nearly 150 Turbolites and ATEX Turbolites. They have trained personnel on site to maintain the lights.

WOLF AIRLAMP ATEX TURBOLITE TECHNICAL INFORMATION

The following table explains the technical specification differences for the Wolf ATEX Turbolite range of airlamp – should you require support or advice on selecting the correct hazardous area airlamp please do not hesitate to contact us.

| Wolf ATEX Turbolite Part Reference | Wolf A-TL44A | Wolf A-TL44B | Wolf A-TL45A | Wolf A-TL45B | |

| Airlamp Description | Safety Bay Light, Compressed Air Powered | Safety Flood Light, Compressed Air Powered | |||

| Hazardous Area Code | ATEX | II 2 GD II T4 (Tamb = 55°C) T135°C | |||

| Mining | – | I M2 | – | I M2 | |

| FM | Class 1 Div 1 Groups A, B, C, D. T4 Ta = 55°C | ||||

| Apparatus Standards | EN1127:1998 | ||||

| Type of Protection | Technical File | ||||

| Area of Hazardous Classification (Gas) | Zones 1 and 2, Gas Groups IIA, IIB, IIC | ||||

| Temperature Classification (Gas) | T4 | ||||

| Area of Hazardous Classification (Dust) | Zones 21 and 22 | ||||

| Maximum Surface Temperature (Dust) | T135°C | ||||

| Ambient Temperature | -20ºC to +40ºC | ||||

| ATEX Certificate | SIRA02ATEX5099X | ||||

| Enclosure | Aluminium | Brass | Aluminium | Brass | |

| Lens | Lens Ball Glass/Plastic Dome | Toughened Glass (15mm) | |||

| Beam Type | All-around 360°C Illumination | Flood (as standard) or Spot (to order) | |||

| Light Source | Part Number | A-129 (as standard) / A-159 (alternative) | |||

| Type | Halogen Filled Filament Bulb | ||||

| Volts | 24v | ||||

| Watts | 250w | ||||

| Output | 6000 lm/9000 lm | ||||

| Life | 2000 hrs/200 hrs | ||||

| Power Source | Type | Compressed Air Driven Turbo-alternator | |||

| Air Pressure | 5.0-8.0 bar | ||||

| Consumption | 0.75m3/min | ||||

| Ingress Protection | Once pressurised may be used underwater | ||||

| Weight | 5.5kg | 9.4kg | 7.1kg | 13.5kg | |

WOLF AIRLAMP TURBOLITE TECHNICAL INFORMATION

The following table explains the technical specification differences for the Wolf Turbolite range of airlamps – should you require support or advice on selecting the correct hazardous area airlamp please do not hesitate to contact us.

| Wolf Turbolite Part Reference | Wolf A-TL44 | Wolf A-TL45 | ||

| Airlamp Description | Safety Bay Light, Compressed Air Powered | Safety Flood Light Compressed Air Powered | ||

| Hazardous Area Code | Ex s II T4 | |||

| Apparatus Standards | SFA 3009:1972 | |||

| Type of Protection | “s” special protection | |||

| Area of Hazardous Classification (Gas) | Zones 1 and 2, Gas Groups IIA, IIB, IIC | |||

| Temperature Classification | T4 | |||

| Ambient Temperature | -20ºC to +40ºC | |||

| ATEX Certificate | BASEEFA Ex 78209X* | |||

| Enclosure | Nickel Plated Brass and Gun Metal | |||

| Lens | Ball Glass/Polycarbonate Dome | Toughened Glass (15mm) | ||

| Beam Type | All-around 360° Illumination | Flood (Matt Reflector) (as standard) or Spot (Polished Reflector) (to order) | ||

| Light Source | Part Reference | A-129 (as std) or A-159 (as alt) |

A-129 (as std) or A-159 (as alt) |

|

| Type | Tungsten Halogen Filled Filament Bulb | |||

| Volts | 24v | |||

| Watts | 250w | |||

| Output | 6000 lm – 9000 lm | 6000 lm – 9000 lm | ||

| Life | 2000 hrs – 200 hrs | 2000 hrs – 200 hrs | ||

| Power Source | Type | Compressed Air Driven Turbo-alternator | ||

| Air Pressure | 4.0-8.0 bar | |||

| Consumption | 0.75m3/min | |||

| Ingress Protection | Once pressurised may be used underwater | |||

| Weight | 7.9kg | 12.2kg | ||

| *Special certification conditions | A clean dry air supply must be used. Supply hose must be anti-static. | |||

Portable Lighting for hazardous areas

Wolf Safety Lamp lighting ranges include an extensive range of ATEX and IECEx certified portable lighting for safe use in potentially explosive atmospheres, including hazardous area Zone 1 & Zone 2: explosion proof Wolf handheld torches, headtorches, handlamps with bulb or LED versions.

- Handlamps Wolf | Hazardous Area Zone 1 Zone 2 ATEX

- Torches Wolf | Hazardous Area Zone 1 Zone 2 ATEX

- Headtorches Wolf | Hazardous Area Zone 1 Zone 2 ATEX

- Luminaires & Floodlites Wolf LinkEx | Hazardous Area Zone 1 Zone 2 ATEX

- Handheld Leadlamps Wolf | Hazardous Area Zone 1 Zone 2 ATEX

- Airlamps Wolf | Hazardous Area Zone 1 Zone 2 ATEX

- Floodlights & Worklights Wolf | Hazardous Area Zone 1 Zone 2 ATEX

- Tank Lighting Wolf LinkEx | Hazardous Area Zone 1 Zone 2 ATEX

Wolf | Handlamps | Torches | Headtorches | Tank Lights | ATEX Hazardous Areas

Thorne & Derrick are hazardous area lighting specialists stocking a complete range of portable and permanent fixed lighting including both fluorescent and LED technology in standard linear light fittings, wellglass, high bay and floodlight design certified by ATEX for both Zone 1 and Zone 2 hazardous areas.

ELECTRICAL & PROCESS INSTRUMENTATION EQUIPMENT

FOR EXPLOSIVE ATMOSPHERES

Thorne & Derrick are Specialist Distributors of Hazardous Area & Explosion Proof Equipment with IECEx & ATEX Certifications to the onshore and offshore oil, gas, petrochemicals and process industries.

Key Product Categories: Control Panels | Plugs & Sockets | Isolators | Enclosures & Junction Boxes | Lighting | Control Stations | Motor Starters | Heat Trace Cables & Systems | Gas Detection & Detectors | Fire Detection & Detectors | Heat Detectors | Electrical Heating & Heaters

Trace Heating | System Design & Supply

Further Reading

-

Wolf Airlamp ATEX Turbolite – Data Sheet

Size: 149.28 KB

Wolf Airlamp ATEX Turbolite – Data Sheet

Size: 149.28 KB

-

Wolf Airlamp ATEX Turbolite – Instructions

Size: 14.96 MB

Wolf Airlamp ATEX Turbolite – Instructions

Size: 14.96 MB