Living in the Zone – Rotronic Instruments New ATEX Transmitters and Calibration Rigs for Self-Contained Reliance

Published 29 Sep 2016

- By Chris Dodds : estimated reading time 5 minutes

The Gas and Oil industries are obvious examples of where potentially explosive environments exist, but other industries have their own set of hazardous conditions that need to be monitored and controlled.

Fine particulates from sugar beet processing, wood dust, pharmaceutical powders and vapours from paint spraying processes are also examples of where equipment, including products designed and manufactured for “own” use, are not excluded from the requirements of the ATEX Directive.

In the Dangerous Substances and Explosive Atmospheres Regulations 2002 (DSEAR) an explosive atmosphere is defined as a mixture of dangerous substances with air, under atmospheric conditions, in the form of gases, vapours, mist or dust in which, after ignition has occurred, combustion spreads to the entire unburned mixture.

Atmospheric conditions are commonly referred to as ambient temperatures and pressures. That is to say temperatures of –20°C to 40°C and pressures of 0.8 to 1.1 bar.

The Swiss based company, Rotronic Instruments, have been manufacturing and supplying ATEX transmitters for 20 years. The accuracy, durability and the reluctance of their probes to drift are seen as key attributes for companies who work in challenging conditions.

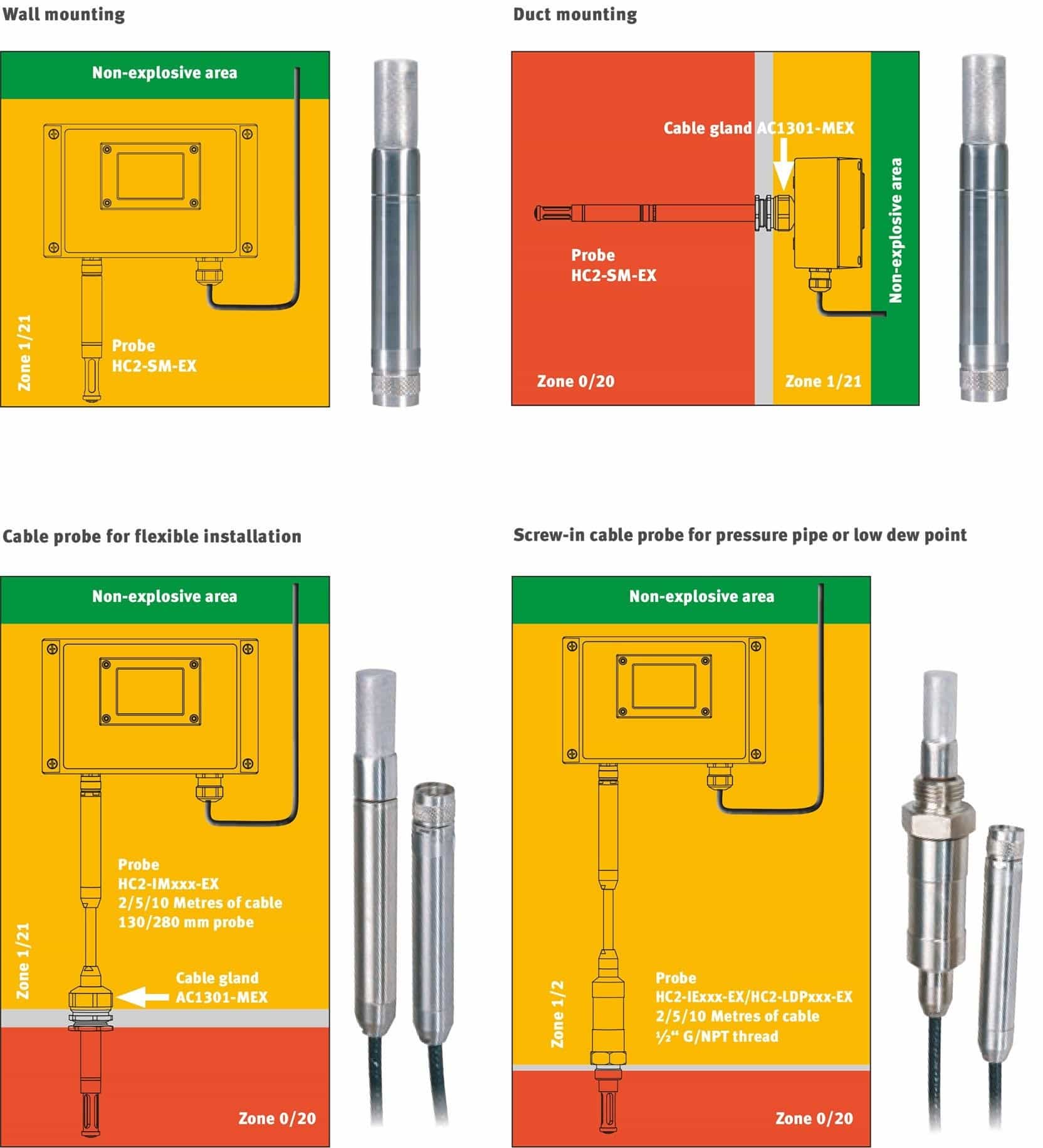

Rotronic’s Hygroflex5-EX range of Wall and Duct mount transmitters comply with all the current ATEX regulations. They have greatly simplified the installation and maintenance of ATEX equipment with galvanic separation and no need for an intrinsically safe power supply.

Their “Hot Swap” probes also significantly reduce line downtime when probes require calibration, enabling the user to attach a replacement sensor in seconds without having to unwire / rewire the transmitter.

All Rotronic probes have a working range of -40°C…+85°C / 0…100 %rh.

The aluminium housing of the transmitter (with display) -10°C…+60°C.

Rotronic Humidity & Temperature Probes

There are a range of probes available for the Hygroflex5-EX series to meet specific applications. Apart from the standard probe pictured above there are also cable probes with 2/5/10 metre cable lengths

Rotronic HC2-IM-EX humidity and temperature probe

For processes that require humidity and temperature measurements under pressure the HC2-IE-EX probe may be employed. Available with either ½”G or ½” NPT thread and with cable lengths of 2/5/10m the probe is pressure resistant to 100 bar / 1450 PSI.

Rotronic HC2-IE-EX humidity and temperature probe

Low Dew Point Measurement

For those wishing to measure trace moisture in bodies such as gas pipes or compressed air systems the HC2-LDP-EX low dew point probe provides highly accurate dew point and temperature measurement up to 100 bar.

Rotronic HC2-LDP-EX dew point and temperature probe

Diagramatic layout for various Zone applications

Islands of Self-Sufficiency

Layered on top of the DSEAR are a company’s individual practices and processes which determine how often instrumentation needs to be calibrated. In order to be self-sufficient, whether from a geographical or process driven perspective, many companies have also taken on board the Rotronic HygroGen2 humidity and temperature generator. The HygroGen2 sets a new standard in terms of portable calibration.

The generator is not exclusively for use with Rotronic probes. Many different manufacturers’ instruments can be calibrated by use of interchangeable diameter port sleeves, clear acrylic and even custom made doors. The user simply enters the required temperature and humidity set points to build a calibration profile.

The range of the Hygrogen2 is:

- 0….60°C (-5….60°C with optional range extension)

- 5….95 %rh (2….99 %rh with optional range extension)

Temperature control stability at equilibrium is better than ± 0.02 °C whilst humidity control stability is better than 0.1 %RH.

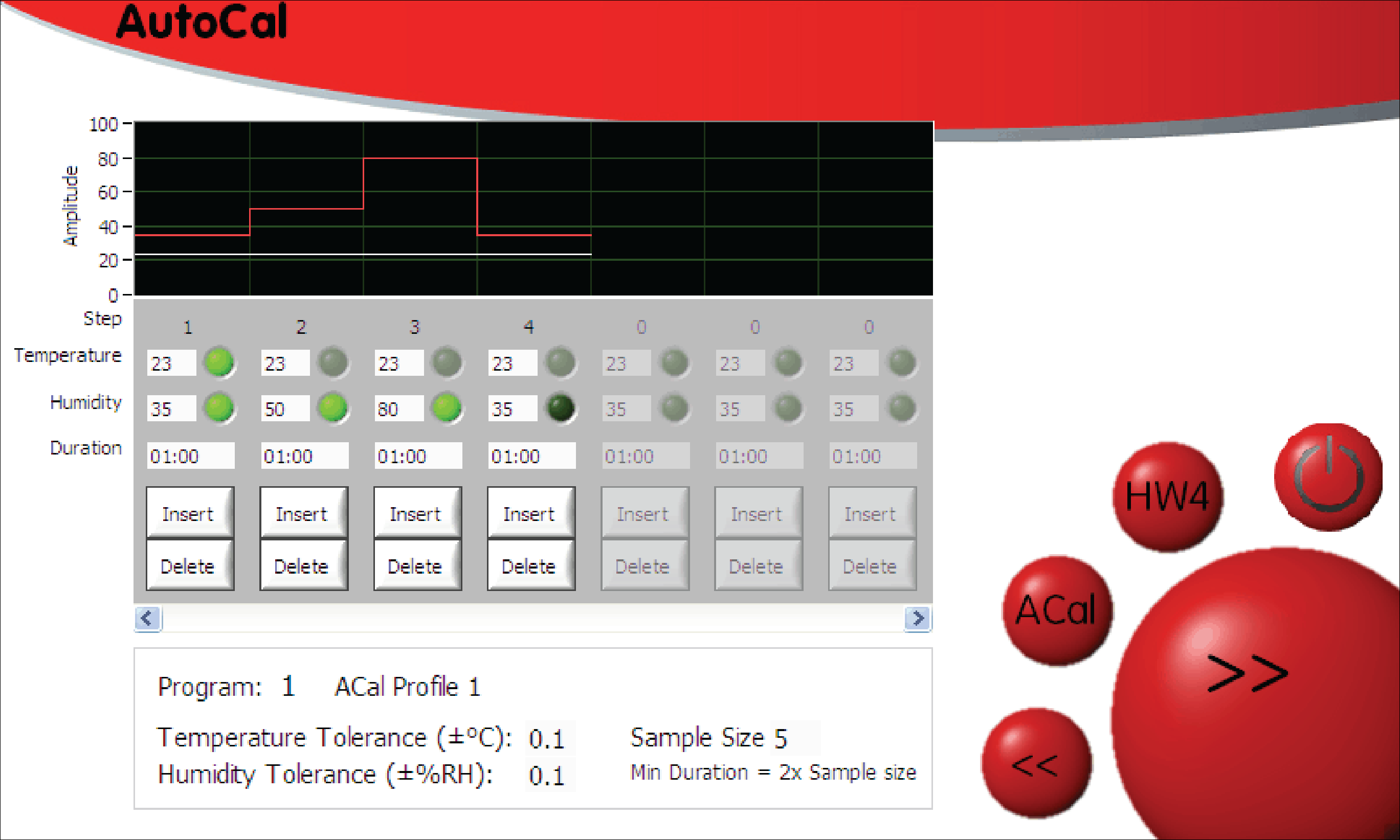

AutoCalibration

One of the main benefits of the HygroGen2, when used in conjunction with Rotronic’s HC2 series probes, is the ability to automatically calibrate the probes (and adjust if required). The AutoCal feature also creates a PDF calibration certificate for each probe under test.

20 storable programmes each with 200 set points provide the flexibility to quickly recall standard profiles for efficient use. Humidity equilibrium between set points is typically achieved in around 5 minutes – a considerable time saving when compared to using calibration salts!

“The installation of the Rotronic ATEX transmitters on a blending suite was simple and the hot swap probes will virtually eliminate line downtime.

The calibration of the probes is now so quick that we even adjusted them out, and back in, just to see how it would work and found the adjustments very logical and easy to complete.

For us, these new probes along with the HydroGen2 chamber represent a huge step forward in the calibration of temperature and humidity instrumentation” – Dave Gregson, GlaxoSmithKline

Reducing uncertainty in uncertain environments

At the very highest level of measurement such as National Standards Laboratories, MBW chilled mirror hygrometers are considered to be the most accurate, reliable and consistent humidity measurement technology available. They are a primary reference standard against which other sensors are calibrated.

As well as calibration laboratories, MBW chilled mirrors are used in Oil and Gas applications, chemistry laboratories and throughout meteorological, processing, manufacturing, engineering and storage industries across a dew/frost point range of -95°Cfp to +95°Cdp and pressures up to 200 bar.

Rotronic has worked closely with MBW, to integrate their products into the HygroGen2 portable temperature and humidity calibration system. Particularly well suited is the MBW 473 Dew Point Mirror, whose RP2 measuring head is designed to be directly inserted into the working volume of the HygroGen2 chamber and work across its full range. Temperature and humidity probes from all manufacturers can be calibrated with typical expanded measurement uncertainty at ambient conditions of less than 0.7 %rh

More Reading

- ATEX Transmitters For Hazardous Area Temperature & Humidity Measurement From Rotronic

- How Much Does It Cost If Your Production Capabilities Are Down For An Hour?

- ATEX Certified Humidity & Temperature Sensors – Rotronic HygroFlex5-EX

ELECTRICAL & PROCESS INSTRUMENTATION EQUIPMENT

FOR EXPLOSIVE ATMOSPHERES

Thorne & Derrick are Specialist Distributors of Hazardous Area & Explosion Proof Equipment with IECEx & ATEX Certifications to the onshore and offshore oil, gas, petrochemicals and process industries.

Key Product Categories: Control Panels | Plugs & Sockets | Isolators | Enclosures & Junction Boxes | Lighting | Control Stations | Motor Starters | Heat Trace Cables & Systems | Gas Detection & Detectors | Fire Detection & Detectors | Heat Detectors | Electrical Heating & Heaters

Trace Heating | System Design & Supply