Hazardous Area & Process Heating For Zone 1 & Zone 2 Locations

Thorne & Derrick International | The Hazardous Area Heating Specialists

◊ UK & EXPORT SALES ◊ TECHNICAL SUPPORT ◊ BEST PRICES ◊ STOCK

◊ hazardous area & explosive atmospheres ◊

Zone 1 & Zone 2

Hazardous Area Heating

Explosive Atmospheres & Hazardous Area Electrical Heating Products

International Distributor, World Class Service

Thorne & Derrick International are leading UK and Export distributors of the most comprehensive range of hazardous area heating products, certified according to ATEX and IECEx classifications, for safe use in potentially explosive atmospheres in the oil, gas and petrochemical industries.

We are acknowledged industry experts in providing Electrical Heating Solutions for explosive atmopheres – we are partners with world leading manufacturers including EXHEAT, Thermon, Hazloc, Chromalox and Emerson.

To fulfil the requirements of our global client base, we can supply explosion-proof heating equipment with cross border certifications such as ATEX, IECEx and EAC-EX as well as country specific certifications certified for use in Zone 1 & 21 (Gas) and Zone 2 & 22 (Dust).

- Water Heaters

- Line Heaters

- Immersion Heaters

- Air Warmers & Fan Heaters

- Portable Heaters

- Drum Heaters

- IBC Container Heaters

- Gas Bottle Heaters

- Heated Hoses

- Trace Heating

Hazardous Area Electrical Heaters | International Certifications

Hazardous Areas Explained

There are many gases, mists, vapours and dusts that can form explosive atmospheres when mixed with air and exposed to a source of ignition – commonly referred to as a hazardous area zone classified according to the ATEX Directive.

Hazardous area classifications are used to identify and categorize the presence or potential threat of gases in a working area and are specified as Zone 1, Zone 2, Zone 21 and Zone 22 according to the ATEX Directive.

The classification and designation of an area as hazardous enables the correct precautions to be taken over sources of ignition in order to prevent fires and explosions. Hazardous area classification should always be carried out as part of a work place risk assessment.

When assessing the level of risk, hazardous and non-hazardous area classification should be carried out systematically and should be used to determine if hazardous areas exist and to then assign zones to those areas.

The risks from not using the appropriate or properly specified and certified equipment in the wrong areas or zones can be catastrophic with explosion risks endangering personnel and plant.

The Dangerous Substances and Explosive Atmospheres Regulations 2002 (DSEAR) provide a specific legal requirement to carry out a hazardous area study, and document the conclusions, in the form of zones.

Electrical Heating | Pipework, Drums, IBC Containers, Gas Bottles, Tanks & Workspace Heaters. Contact the EX Specialists.

Hazardous Areas Explained

T&D provide greater, in-depth analysis of hazardous areas and electrical heating on our Blog.

Hazardous areas are classified into the following zones according to the concentration levels of flammable gas and the explosion risk potential:

Gases, Vapours And Mists

Zone 1 – Zone 1 hazardous areas are considered to be a place in which an explosive atmosphere consisting of a mixture with air of dangerous substances in the form of gas, vapour or mist is likely to occur in normal operation occasionally.

Zone 2 – Zone 2 hazardous areas are classified as a place in which an explosive atmosphere consisting of a mixture with air of dangerous substances in the form of gas, vapour or mist is not likely to occur in normal operation but, if it does occur, will persist for a short period only.

Dusts

Zone 21 – A place in which an explosive atmosphere in the form of a cloud of combustible dust in air is likely to occur in normal operation occasionally.

Zone 22 – Zone 22 hazardous areas are a place in which an explosive atmosphere in the form of a cloud of combustible dust in air is not likely to occur in normal operation but, if it does occur, will persist for a short period only.

Equipment that is suitable for use in hazardous areas or that has been specifically manufactured for that purpose will typically have an ATEX hexagon marking on for easy identification and in many cases this marking will include a temperature rating expressed as a “T” marking and sometimes a gas group.

These indicate limitations of safe use. Employers and those installing equipment should consider the marking and documentation provided with “Ex” equipment when it is being installed.

Hazardous Area Temperature (T) Ratings

In addition to direct ignition sources, hazardous area rated equipment must also meet relevant temperature ratings in order to be classified as safe for use. The temperature should be considered at which a mixture of vapour, gas and dust would ignite and become a self-sustaining reaction in the area in which the equipment would operate.

This temperature (T) class rating refers to the maximum outside temperature equipment can reach and is based upon the auto-ignition temperature of gases.

| Temperature Classification | Maximum Surface Temperature, °C | Ignition Temperature of gas or vapour, °C |

| T1 | 450 | >450 |

| T2 | 300 | >300 |

| T3 | 200 | >200 |

| T4 | 135 | >135 |

| T5 | 100 | >100 |

| T6 | 85 | >85 |

Hazardous Area Heaters: Drums, IBC’s & Gas Bottle Heating

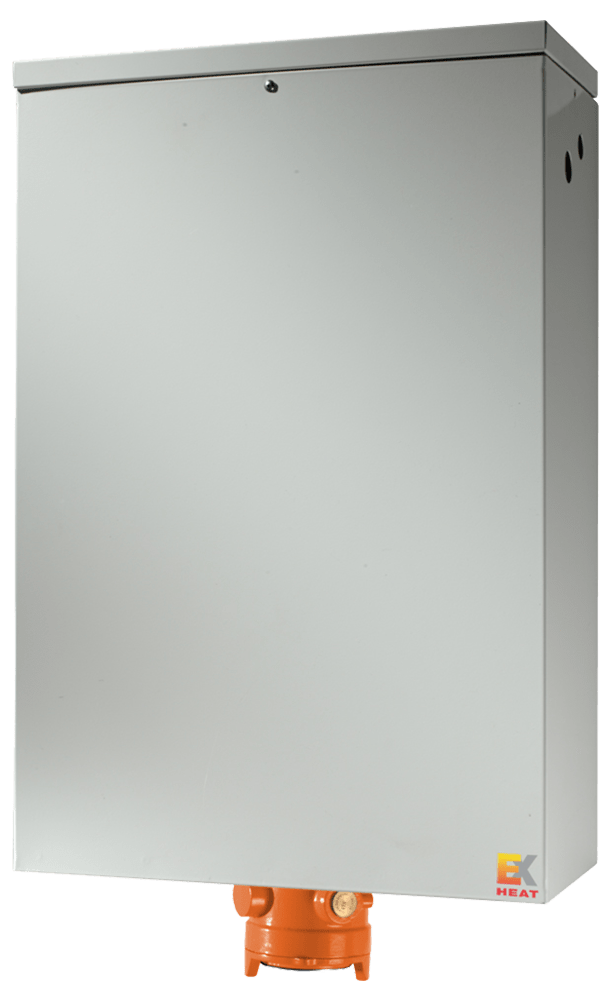

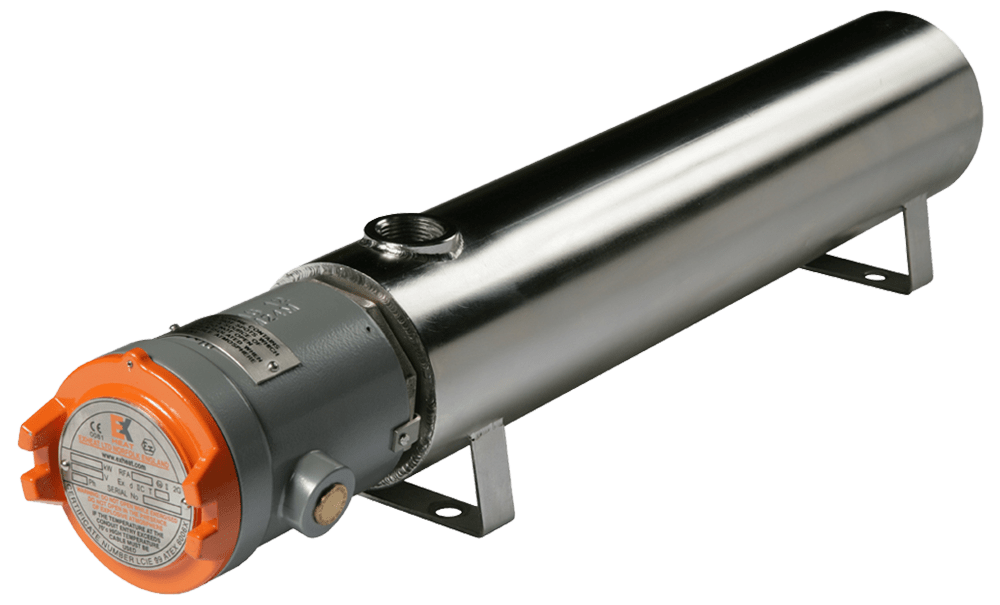

EXHEAT

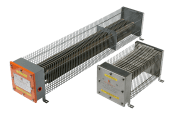

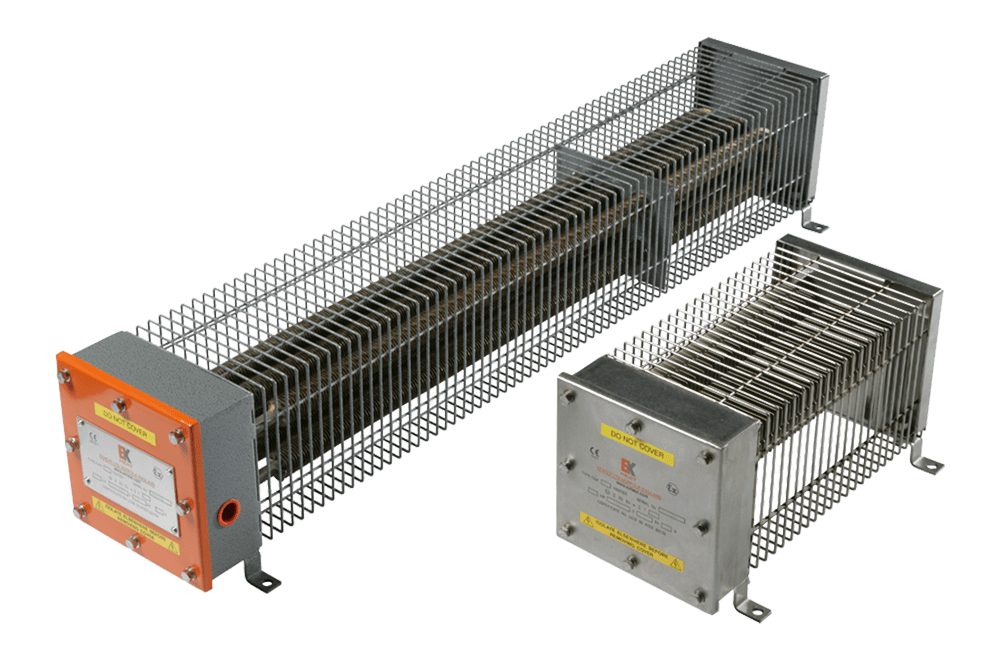

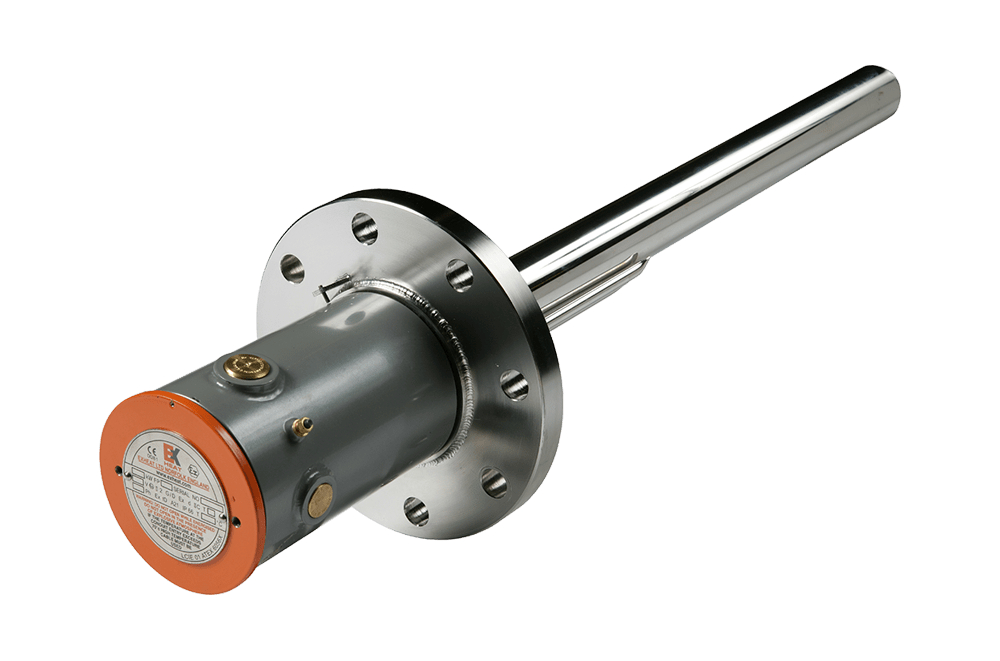

T&D are Main Distributors for the EXHEAT range of hazardous area heating equipment including air heaters, immersion heaters, water heaters, line heaters and thermostats suitable for Zone 1 & 21 and Zone 2 & 22.

| Air Heaters & Warmers | Immersion Heaters | Water Heaters | Line Heaters | Thermostats |

|

|

|

|

|

Some Typical Electrical Heating Applications

➡ Should you require assistance with a specific process or space heating application or selection of the correct electric heater please do not hesitate to contact us – for specialist custom and complex surface heating applications please see our range of silicone heaters.

| Air | Air Handling | Air Heating | Air Thermostats | Air Conditioning | Aircraft Hangers | Ammunition | Analyser Houses |

| Anti-Ice Stations | Aviation Fuel Test Areas | Battery Rooms | Canopy | Catalyst Oxidastion | Flameproof Areas | Chemical Injection Systems | Chemical Plant Warehouses |

| Chemical Plants | Chemical Stores | Containers | Crane Cabs | Dairies | Deluge Skids | Dimplex Heaters | Dog Houses |

| Drilling Floors | Drying Ovens & Rooms | Dust Extractors | Electrical Substations | Equipment Cabins | Explosive Stores | Fire Equipment Skids | Fire Shelters |

| Firework Factories | Flammable Liquid Stores | FPSO | Frost Protection | Gas Installations | Gas Regeneration | Gas Storage | Generator Rooms |

| Resin Drying Rooms | Safe Containers | Salty Atmospheres | Sewage Plants | Shipping Containers | Silo Heaters | Site Cabins | Skids |

| Solvent Storage | Space Heating | Spray Booths | Substations HV | Sugar Refineries | Surface Mining Heaters | Test Rigs | Ventilation |

Process Heating

| Fuel Gas | Glycol Regeneration | Crude Oil | Hydrocarbon Liquids | Seawater | Nitrogen | Air |

| Oxygen | Process Gas | Heat Transfer Liquids | Water | Hot Water Calorifiers | HVAC |

| Natural Gas | Flammable Gas | Fuel Oil | Hydrocarbons | Steams | Solvents |

Offshore Oil & Gas Electrical, HVAC & Process Instrumentation Equipment

Thorne & Derrick | Experts in Equipment for Explosive Atmospheres

Specialist Distributors of Hazardous Area & Explosion Proof Equipment with IECEx & ATEX Certifications to the onshore and offshore oil, gas, petrochemicals and process industries.

Key Product Categories: Control Panels | Plugs & Sockets | Isolators | Enclosures & Junction Boxes | Lighting | Control Stations | Motor Starters | Heat Trace Cables & Systems | Gas Detection & Detectors | Fire Detection & Detectors | Heat Detectors