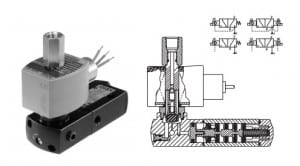

ASCO EV 8551 Ex Proof ATEX Solenoid Valve (Explosion Proof Encapsulated Coils)

T&D – ASCO Numatics Authorised Distribution Channel. Process and flow control of air, gas, water, oil and steam using advanced solenoid valve technology.

ASCO EV 8551 Explosion Proof Encapsulated Coils

ASCO EV 8551 explosion proof encapsulated coils are part of the hazardous area solenoid valve range suitable for use in ATEX Zone 1 and Zone 2 hazardous area applications.

The ASCO EV 8551 is a compact spool valve that is available in single and dual solenoid constructions.

The solenoid valve has a unique design that combines hard T-seals and flexible o-rings, provides bubble-tight shutoff, resistance to dirt and multimillion cycle life controlling air or inert gas.

ASCO EV 8551 Hazardous Area Solenoid Valve With Manual Operator

EV 8551 is also available in low power and intrinsically safe construction.

The nominal ambient working temperature ranges for the ASCO EV 8551 hazardous area solenoid valve are Aluminum AC: 5˚F to 125˚F (-15˚C to 52˚C) DC: 5˚F to 104˚F (-15˚C to 40˚C), Brass AC: -40˚F to 125˚F (-40˚C to 52˚C) and Stainless Steel DC: -40˚F to 104˚F (-40˚C to 40˚C)

ASCO EV 8551

Solenoid Valve HAZARDOUS area Certifications

CSA UL FM ATEX IECEX

| ASCO Valve Series | Type | Pipe Size (in) | Max. Cv (Kv) |

CSA |

UL FM |

ATEX IECEx |

| ASCO EV 8551 | 3-Way/4-Way Valve | 1/4 | 86 (.75) | ✓ | ✓ | ✓ |

Contact T&D for copy hazardous area certificates – for complete technical specification and certification refer to the ASCO EV 8551 download opposite.

Hazardous Area Classification ATEX

ATEX IECEx Certified Valves

ATEX II 2G Ex d mb IIC T

ATEX Gb II 2D Ex mb IIIC T Db IP67

Hazardous Area Classification IECEx

IECEx Ex d mb IIC T

IECEx Gb Ex mb IIIC T Db

ASCO EV 8551 Hazardous Area Solenoid Valve Construction

| Valve Parts In Contact With Fluid | |||

| Solenoid Valve Body | Brass | Stainless Steel | 316L Stainless Steel |

| End Cover (Spring end) | Glass-filled Polyamide | Brass | 316L Stainless Steel |

| Spool Valve Internals | Zamak, Stainless Steel, Acetal (POM), Aluminum | Brass, Acetal (POM), Delrin | |

| Pilot End Covers | Aluminum, Black Anodized | Brass | 316L Stainless Steel |

| Core Tube | Stainless Steel | ||

| Core and Plugnut | Stainless Steel | ||

| Springs | Stainless Steel | ||

| Seals and Discs | NBR | ||

| Top Disc | Nylon (PA) | ||

| Core Guide | Acetal | ||

| Seat and Seat Insert | Brass, Acetal | ||

| Shading Coil | Copper | ||

| Rider Ring (low power) | PTFE | ||

ASCO Solenoid Valves, Coils & Enclosures With IECEX & ATEX Hazardous Area Approvals

HAZARDOUS AREA VALVES

ASCO solenoid valves provide flow control in hazardous area industries including oil, gas, petrochem, mining, power and process industries to ATEX (European), IECEx (International), CSA (North America), UL (United States & Canada), NEPSI (China), INMETRO (Brazil) and TR CU (Russia) approvals.

➡ Did you know? T&D are Trained users of Thermon CompuTrace software to enable the design of steam and electric trace heating systems for frost protection and process temperature maintenance of pipework in industrial and hazardous area locations.

➡ Read Blog: ATEX Solenoid Valves – ASCO Valves for International Hazardous Area Installations