SICK TRANSIC100LP | Gas Transmitter For Measuring Oxygen

Gas Transmitters

Gas Transmitters

SICK TRANSIC100LP

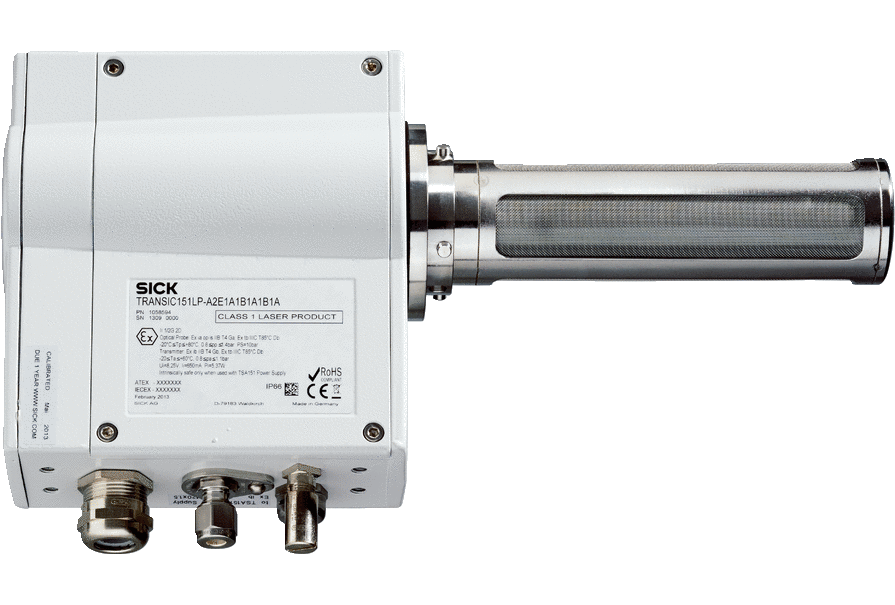

TRANSIC100LP is a Gas Transmitter manufactured by SICK which makes measuring oxygen in the process simple.

The TRANSIC100LP is a rugged transmitter which uses Tunable Diode Laser Spectroscopy (TDLS) to reliably measure O2 (Oxygen).

A technology more common in the world of high-tech gas analysis, is now being used in a field instrument at an attractive price with easy installation, a long life, low-maintenance, and suitability to be used in explosive atmospheres and hazardous areas.

Typical Applications for SICK TRANSIC100LP Gas Transmitters

- Monitoring of inert gas blanketing in tanks and vessels

- O2 measurement in process gases

- Measurements in potentially explosive atmospheres

- Process monitoring in fermenters and bioreactors

- Room air monitoring

- Quality monitoring for the production of technical gases

- Replacement of extractive paramagnetic oxygen analysers and electrochemical cells

➡ T&D stock Process Instrumentation for industrial processes, explosive atmospheres & hazardous areas.

Pressure Gauges | Solenoid Valves | Flowmeters | Pressure Transmitters & Sensors | Control Valves | Temperature Sensors

SICK TRANSIC100LP Gas transmitter

Features

- High selectivity due to high spectral resolution

- No calibration required

- No moving parts: minimal wear and tear

- Heated multipath measurement cell

- Hot-wet measurement technology

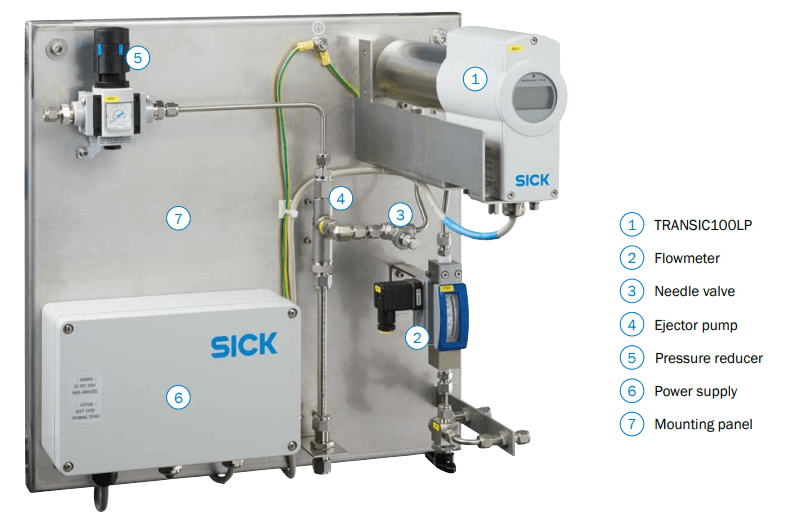

- Optimal adaptation to measuring task through suitable gas conditioner

- High reliability during operation

- Can also be used in harsh ambient conditions

- Easy integration into existing extractive systems

- No problematic test gases required

➡ T&D also distribute the range of SICK In-Situ Gas Analysers & SICK Extractive Gas Analysers

SICK TRANSIC100LP Gas Transmitters

SICK TRANSIC100LP

Technical SPECIFICATION

| Measured Values | O2 |

| Measurement Principles | Diode laser spectroscopy (TDLS) |

| Measuring Ranges | O2: 0 … 5 Vol.-% / 0 … 100 Vol.-% |

| Response Time (t90) | ≤ 10 s |

| Accuracy | ≤ 0.2 Vol.-% |

| Zero Point Drift | ± 0.1 Vol.-%: per year |

| Process Temperature | –20 °C … +80 °C |

| Process Pressure | 800 hPa … 1,400 hPa |

| Ambient Temperature | –20 °C … +60 °C |

| Storage Temperature | –30 °C … +80 °C |

| Hazardous Area Approvals | IECEx Sender/receiver unit: Ex op is / ib IIB T4 Ga/Gb; Ex ib tb op is IIIC T85°C Db TSA151 connecting unit: Ex eb mb [ib] IIB T4 Gb; Ex tb [ib] IIIC T85°C Db ATEX Sender/receiver unit: II 1/2 G Ex op is / ib IIB T4 Ga/Gb; II 2 D Ex ib tb op is IIIC T85°C Db TSA151 connecting unit: II 2 G Ex eb mb [ib] IIB T4 Gb; II 2 D Ex tb [ib] IIIC T85°C Db NEC/CEC (US/CA) Sender/receiver unit: Class I, Division 2, Group A, B, C, D T4 Measuring probe: Class I, Division 1 + 2, Group A, B, C, D T4 |

| Electrical Safety | CE, FM |

| Enclosure Rating | IP66 |

| Analog Outputs | 1 output active: 0/4 … 20 mA, + 500 Ω 1 output active: 0/4 … 20 mA, + 200 Ω Only for ATEX/IECEx version TRANSIC151LP |

| Digital Outputs | 1 relay contact: + 30 V AC, 1 A / 60 V DC, 0.5 A 1 NAMUR output: Only for ATEX/IECEx version TRANSIC151LP |

| Communication Interface | Serial, USB Remark: Not for the ATEX/IECEx version, Not approved for Ex-applications Type of fieldbus integration: RS-232, RS-485 Function: Proprietary service interface |

| Number | 1 |

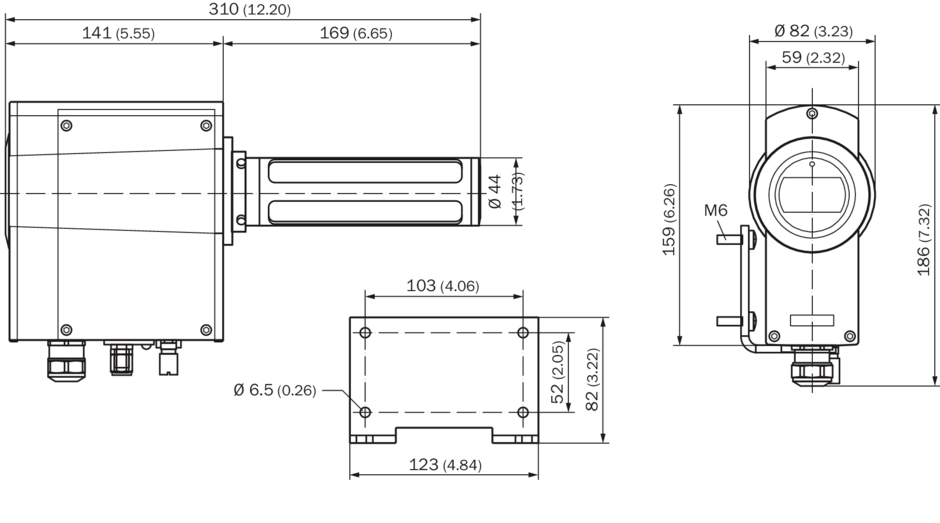

| Dimensions (W x H x D) | Dimensions may vary. For details, see the dimensional drawings |

| Weight | 2.2 kg |

| Material In Contact With Media | Stainless steel 1.4404 (AISI 316L), Kalrez®, EPDM, PTFE, SiN, MgF2, polymer coating |

| Mounting | Flange for direct installation in the process, Wall-mounting bracket for ambient air measurement, Wall-mounting bracket for measurement with measuring gas cell |

| Power Supply | Voltage: 24 V DC, TRANSIC151LP: 21.6 … 26.4 V, For ATEX/IECEx version via TSA151 connecting unit, a PELV power supply is mandatory Current consumption: ≤ 500 mA Power consumption: ≤ 6 W, TRANSIC151LP: ≤ 5.2 W |

| Corrective Functions | Adjustment with ambient air or test gases |

| Test Functions | Contamination check |

SICK TRANSIC100LP with wall bracket for ambient measurements Dimensions in mm (inch)

ELECTRICAL & PROCESS INSTRUMENTATION EQUIPMENT

FOR EXPLOSIVE ATMOSPHERES & Hazardous Areas

Thorne & Derrick are Specialist Distributors of Hazardous Area & Explosion Proof Equipment with IECEx & ATEX Certifications to the onshore and offshore oil, gas, petrochemicals and process industries.

Key Product Categories: Control Panels | Plugs & Sockets | Isolators | Enclosures & Junction Boxes | Lighting | Control Stations | Motor Starters | Heat Trace Cables & Systems | Gas Detection & Detectors | Fire Detection & Detectors | Heat Detectors | Electrical Heating & Heaters